Soil humus extraction and purification method

A purification method and technology of humus, which is applied in the field of extraction and purification of soil humus, can solve the problems of low data comparability, achieve the effect of improving extraction yield, reducing production cost, and avoiding the consumption of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The humus in the soil of Inner Mongolia grassland area is extracted, and the implementation method is as follows:

[0025] Grassland soil pretreatment, the air-dried soil sample was ground through a sieve with a 2mm aperture, and mixed for use in experiments.

[0026] 1) Coarse separation of three components of grassland soil humus:

[0027] Weigh 55g of the above-mentioned soil sample passed through a 2mm sieve, place it in a 600ml centrifuge bottle, then add 550mL of 0.13M HCl and shake it well, empty the centrifuge bottle of 50mL of empty bottle volume, and promote the violent vibration of the liquid in the bottle during the shaking process. It is beneficial to fully contact the soil with the extractant and improve the extraction yield. Sonicate in a 150W ultrasonic cleaner at room temperature for 30min, then shake at a constant temperature of 25°C at a rate of 150rpm for 1h, and then centrifuge at a speed of 3500rpm for 30min. The residue in the lower layer contain...

Embodiment 2

[0038] The humic substances extracted from the above examples have deashed (DHA, DFA and DHu) and non-ashed (HA, FA and Hu) products, and their properties were analyzed by FTIR and titration experiments.

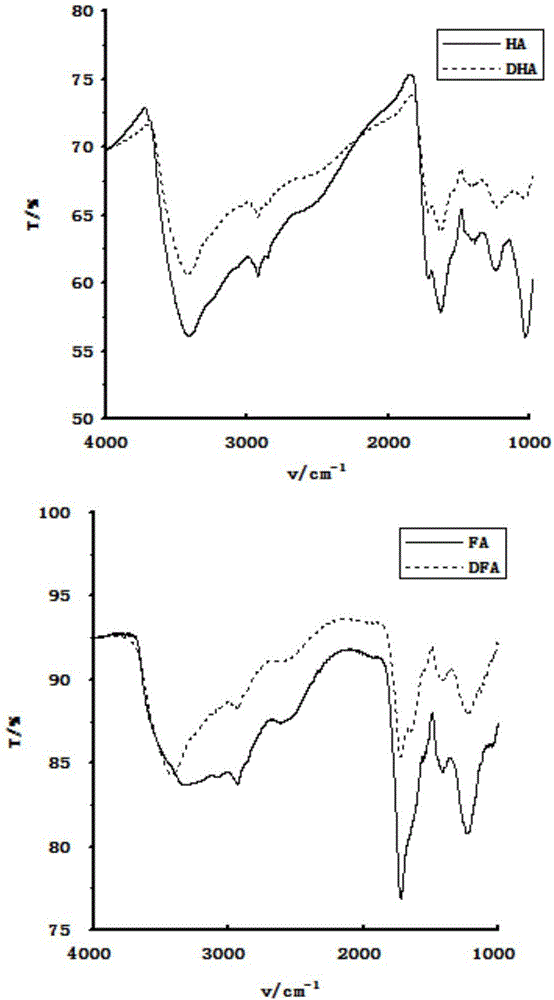

[0039] Take 1mg samples of each of DHA, HA, DFA and FA, mix each sample with 100mg of KBr, grind them thoroughly, press them into tablets and dry them in an infrared drying oven to remove the influence of water molecules in the samples. Measured on a Fourier transform infrared spectrometer, the measurement parameters are: resolution 4cm -1 , measuring range 4000-400cm -1 (see image 3 ).

[0040] Depend on image 3 It can be seen that humic acid and fulvic acid molecules have the same characteristic absorption peak, among which 3600-3100cm -1 The broad peaks are -OH (free or associated), -NH stretching shock absorption peaks, 2960cm -1 、2850cm -1 Symmetrical stretching vibration absorption peaks of methyl or methylene respectively, 1725cm -1 It is the carbonyl stretch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com