Vacuum film-plating process for gate pattern of semiconductor chip shielded by mask at high accuracy

A processing technology and semiconductor technology, which can be used in vacuum evaporation plating, photoengraving process exposure devices, semiconductor/solid-state device manufacturing, etc., and can solve the problems of secondary metal film blistering, silver flakes shifting, and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

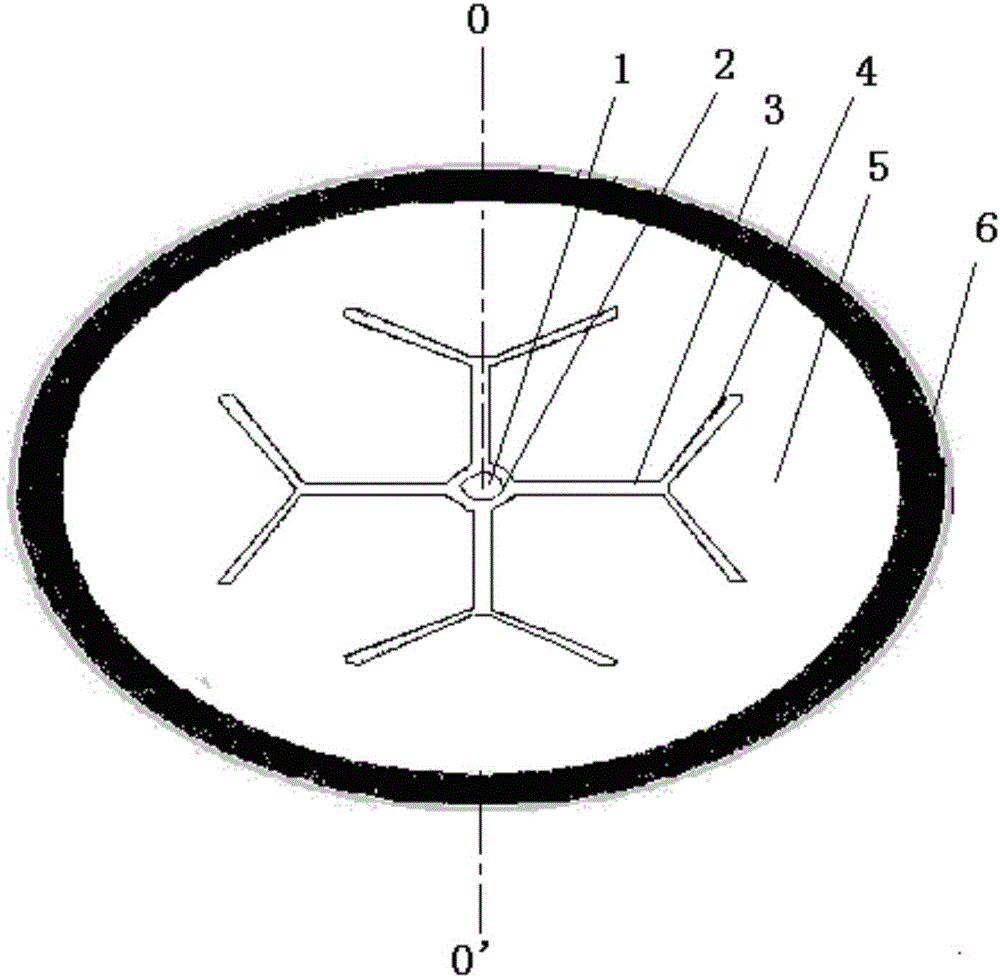

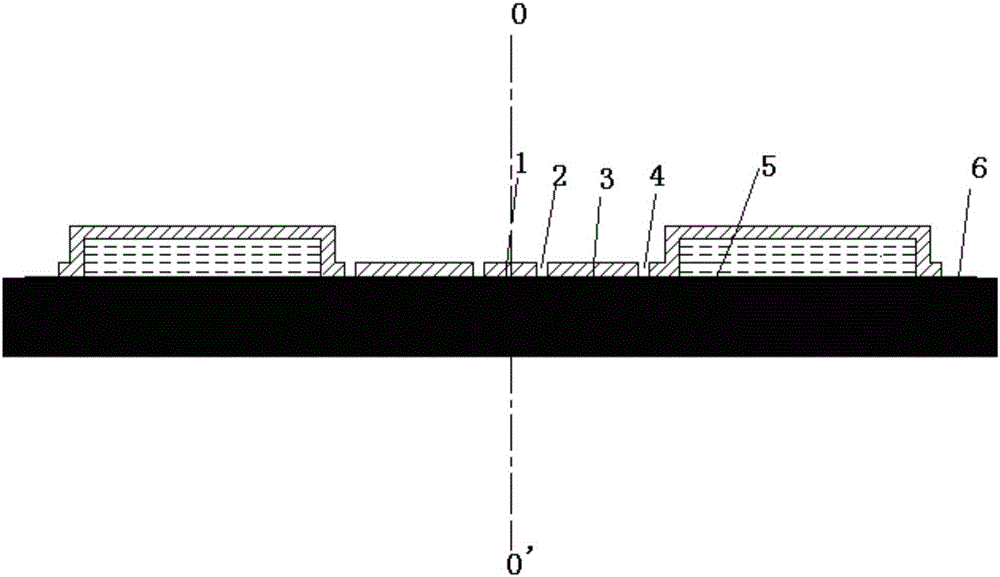

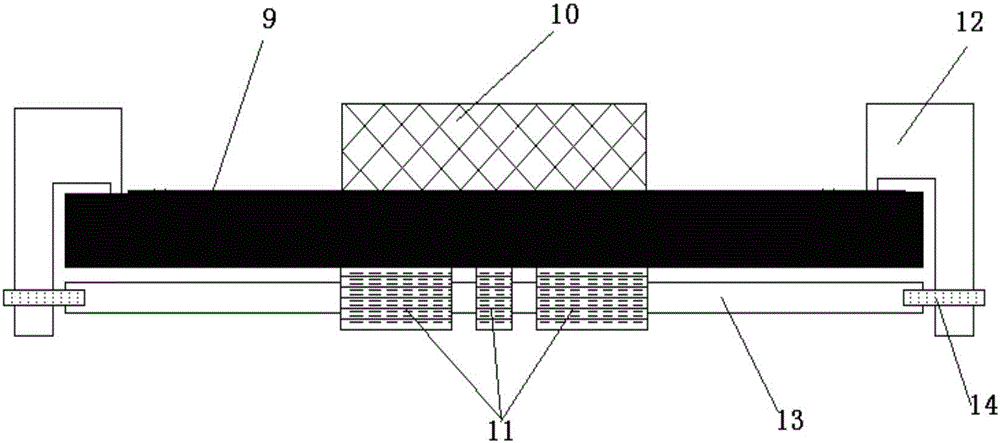

[0031] Such as Figure 1-7 As shown, the high-power thyristor semiconductor device includes a semiconductor chip 9, and the semiconductor chip 9 is provided with a central gate pattern 1, an enlarged gate pattern 3, a cathode pattern 5 and a mesa pattern 6. The first layer of metal film 8 is distributed on the cathode pattern 5 on the semiconductor chip 9; the second layer of metal film 7 is distributed on the first layer of the central gate pattern 1 and the enlarged gate pattern 3 and cathode pattern 5 on the semiconductor chip 9 On the metal film 8; the central gate pattern 1 metal film and the enlarged gate pattern 3 metal film are separated by the isolation line 2; the enlarged gate pattern 3 metal film and the cathode pattern 5 metal film are separated by the isolation line 4, and the cathode pattern 5 metal can be seen The film is composed of a first layer of metal film 8 and a second layer of metal film 7; the second layer of metal film 7 has good ohmic contact with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com