Manufacturing method of silicon-based MEMS micro nano through hole structure

A manufacturing method and a technology of through-silicon vias, which are applied in the direction of microstructure technology, microstructure devices, and manufacturing microstructure devices, etc., can solve the problems of unsuitability for large-scale micro-nano manufacturing, poor consistency and stability, and complicated thinning and polishing. , to achieve good consistency in different batches, simple steps, and low difficulty in achieving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

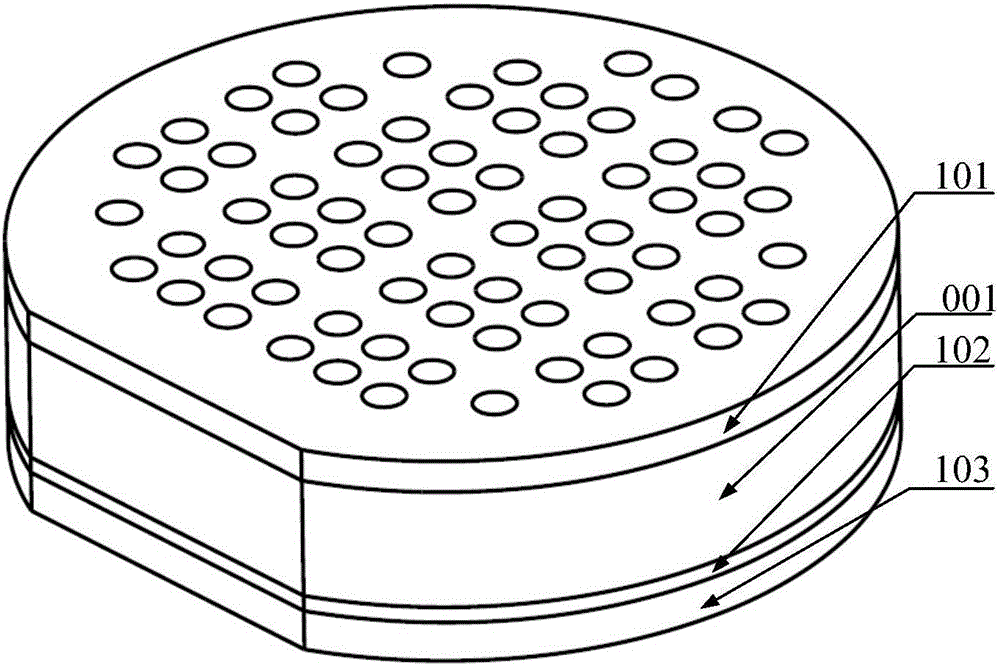

[0040] Such as figure 1 Shown is a schematic diagram of a three-dimensional structure of a silicon MEMS through-hole structure micro-nano implementation method. It can be seen from the figure that a method for manufacturing a silicon-based MEMS micro-nano through-hole structure includes the following steps:

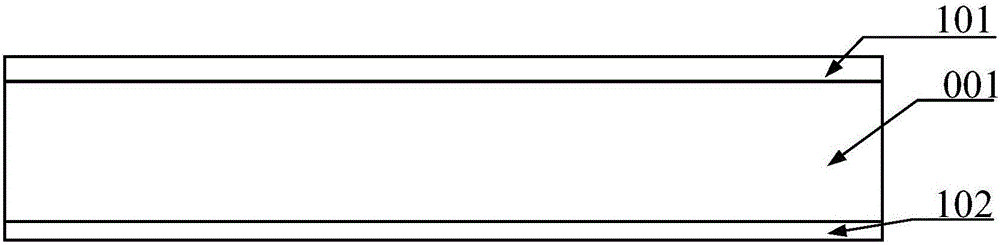

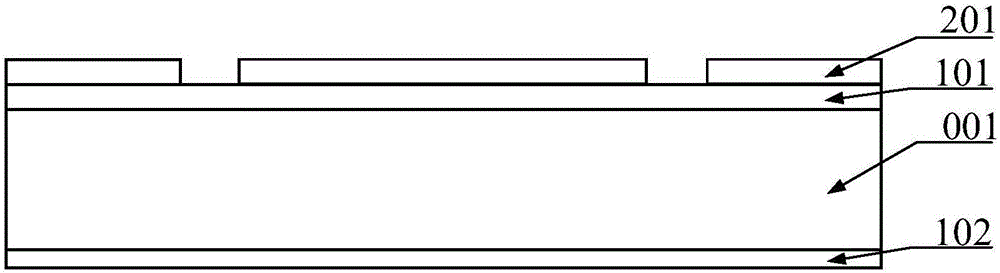

[0041] Step (1), such as figure 2 Shown is a schematic diagram of the steps of depositing a silicon dioxide film / metal film. It can be seen from the figure that a silicon dioxide film layer 101 is grown on the upper surface of the silicon wafer substrate 001, and a silicon dioxide film layer 101 is grown on the lower surface of the silicon wafer substrate 001. Deposit a layer of metal thin film layer 102; wherein, the method for growing silicon dioxide thin film layer 101 is PECVD method, thermal oxidation method or LPCVD method, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com