Application of sodium alginate oligose and derivative to treatment of pain

A technology for oligosaccharides and derivatives of alginate, which is applied to the preparation of sugar derivatives, sugar derivatives, and sugar derivatives, etc., can solve the problems of large molecular weight of alginate, limitation of drug application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

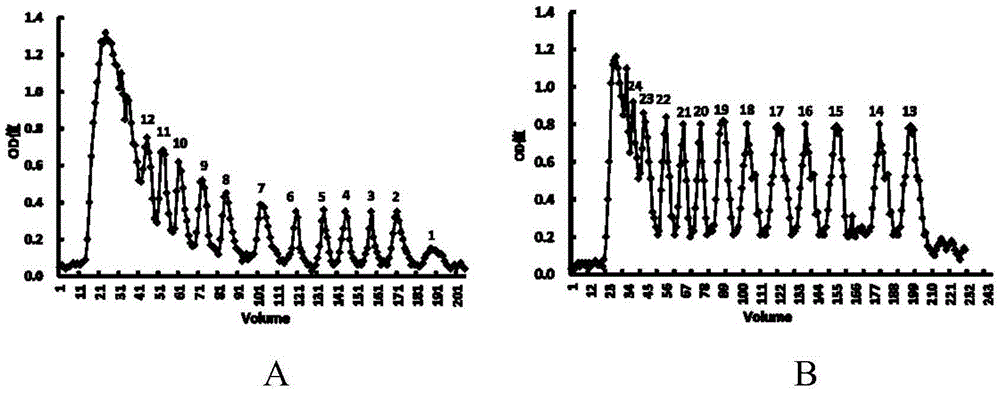

[0044] Embodiment 1 Preparation of algin oligosaccharides

[0045] Weigh 1 g of polymannuronic acid sodium salt (weight average molecular weight 8235 Da, provided by Shanghai Green Valley Pharmaceutical Co., Ltd.), and add appropriate amount of distilled water to prepare a 1% (weight percent) aqueous solution of polymannuronate sodium. The pH value of the 1% aqueous sodium polymannuronate solution was adjusted to 4 with hydrochloric acid, and then the aqueous solution was placed in an autoclave. The reaction was heated at 110°C for 4 hours. The reacted solution was taken out from the autoclave and allowed to cool. After cooling, the pH value of the reacted solution was adjusted with NaOH solution to obtain a neutral liquid. Under the condition of stirring, the neutral liquid was slowly added into ethanol in an amount 4 times the volume of the liquid, alcohol precipitation was carried out and the mixture was allowed to stand overnight. The solid matter obtained by alcohol pr...

Embodiment 2

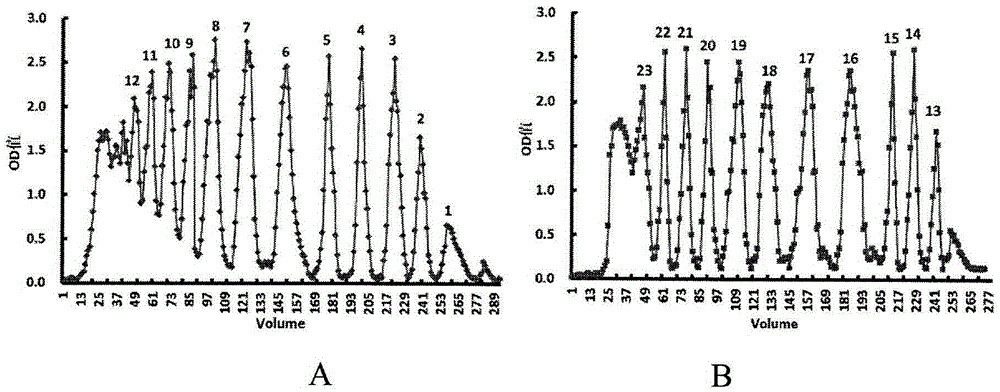

[0047] Example 2 Preparation of algin oligosaccharide oxygen hydrolysis product

[0048] Take 5 g of the above-mentioned crude alginate oligosaccharides that have not been separated by molecular exclusion chromatography to prepare a 5% (weight percent) aqueous solution. Fresh oxidant copper hydroxide was prepared by adding 25 ml of 5% (weight percent) copper sulfate solution to 50 ml of 10% (weight percent) sodium hydroxide solution and mixing immediately. The fresh oxidant copper hydroxide was immediately added to 40ml of the above-mentioned 5% (weight percent) alginate oligosaccharide solution, and heated in a boiling water bath until no brick-red precipitate was produced. The reaction system was centrifuged to remove precipitates to obtain a supernatant. Get a little supernatant and add the oxidizing agent again to check whether there is brick red precipitate. If there is still a brick-red precipitate, then continue to react all the supernatant obtained by the centrifugat...

Embodiment 3

[0050] Example 3 Effect of Alginate Oligosaccharide Derivatives on Pain in Mice Induced by Acetic Acid

[0051] 1 Experimental materials

[0052] 1.1 Drugs and reagents

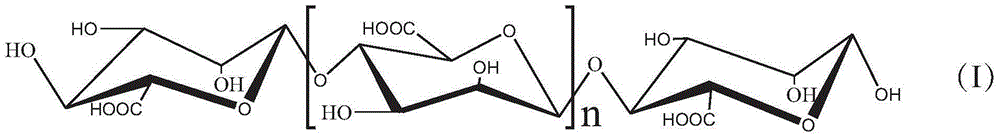

[0053]According to the method of Example 2, a mixture of alginic oligosaccharides (n=2-8, ie components 4-10 in the figure) of formula (II) was prepared. The mixture is off-white powder, easily soluble in water; acetic acid, produced by Tianjin Kaitong Chemical Reagent Co., Ltd.; aspirin, produced by Shijiazhuang Ouyi Pharmaceutical Co., Ltd.

[0054] 1.2 Experimental animals

[0055] Kunming mice, half male and half male, weighing 18-22 g, were provided by Shanghai Xipuer-Bikay Experimental Animal Co., Ltd.

[0056] 2 Experimental methods

[0057] 2.1 Animal grouping, drug administration and treatment

[0058] The mice were randomly divided into 5 groups, namely blank control group, positive drug aspirin 200mg / kg group, alginate oligosaccharide derivatives 25mg / kg, 50mg / kg, 100mg / kg groups, with 10 anim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com