UV offset print freezing-point printing ink and preparation method thereof

An ink and freezing point technology, which is applied in the field of UV offset printing freezing point ink and its preparation, can solve the problems of poor water resistance, slow drying speed, and weak adhesion, and achieve the effects of strong water resistance, fast drying speed, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

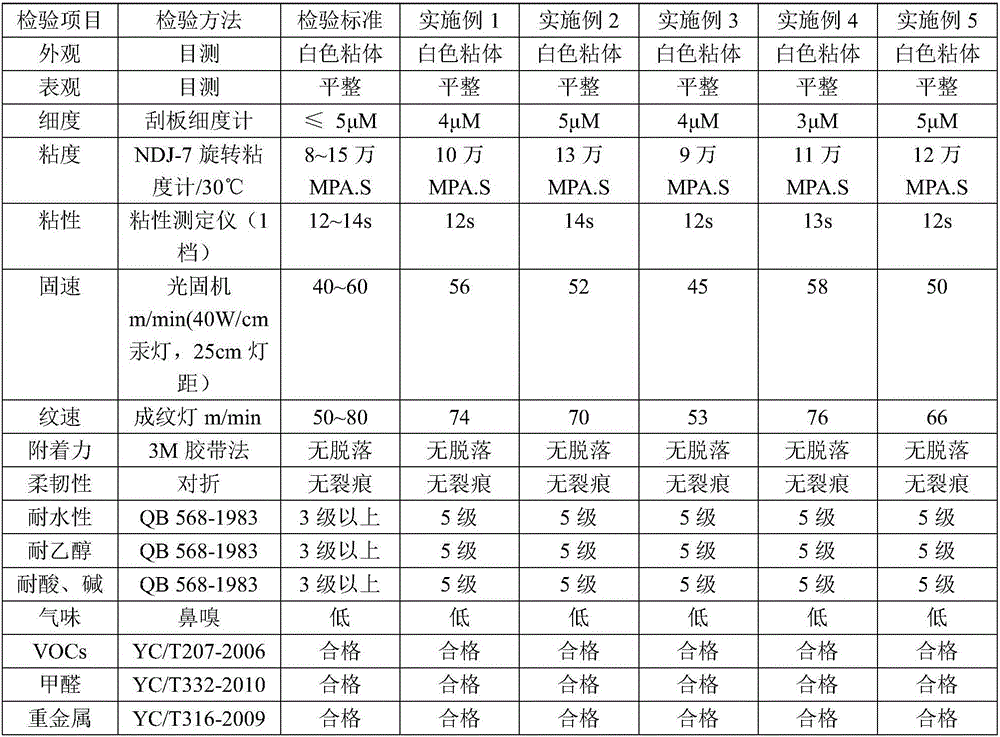

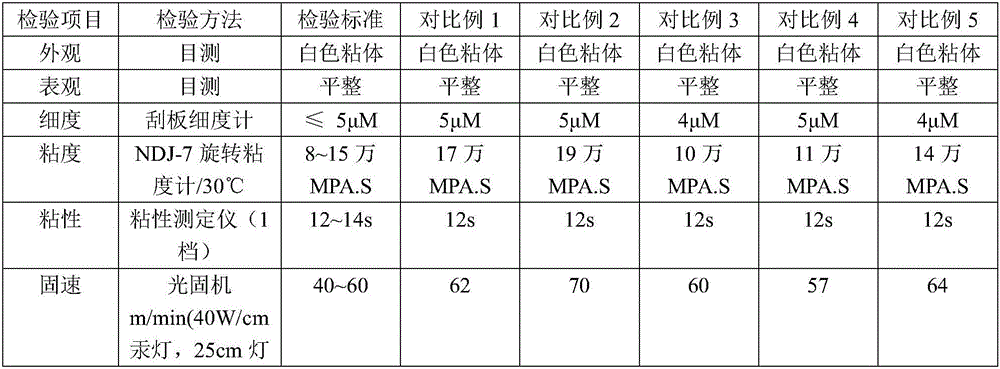

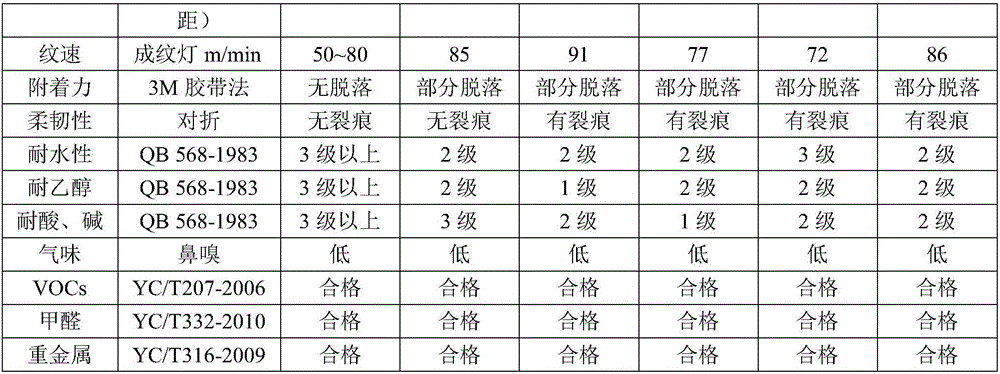

Examples

Embodiment 1

[0032] Embodiment 1, UV offset printing freezing point ink of the present invention and its preparation

[0033] Formula: polymer resin binder 300kg, reactive diluent 300kg, photoinitiator ITX 50kg, PTFE wax powder 80kg and Lubrizol hyperdispersant 325001kg.

[0034] The polymer resin binder is obtained by mixing polyketone resin, polyurethane acrylate resin and polyester acrylic resin in a weight ratio of 1:1.8:1.6.

[0035] The reactive diluent is obtained by mixing trimethylolpropane triacrylate and acryloyl morpholine in a weight ratio of 1:2.

[0036] Preparation method: S1. Mix and boil the photoinitiator of the formulated amount and 1 / 3 of the reactive diluent of the formulated amount to obtain the photoinitiator mixed solution, which is set aside;

[0037] S2. Add the formula amount of polymer resin binder and 2 / 3 formula amount of reactive diluent into the stirring tank, disperse and stir at 600r / min for 20min to obtain the pre-prepared resin liquid, and then add the...

Embodiment 2

[0039] Embodiment 2, UV offset printing freezing point ink of the present invention and its preparation

[0040] Formula: polymer resin binder 500kg, reactive diluent 500kg, photoinitiator 379100kg, nano calcium carbonate 150kg and Lubrizol hyperdispersant 3250020kg.

[0041] The polymer resin binder is obtained by mixing polyketone resin, polyurethane acrylate resin and polyester acrylic resin in a weight ratio of 1:2.4:2.2.

[0042] The reactive diluent is obtained by mixing trimethylolpropane triacrylate and acryloyl morpholine in a weight ratio of 1:4.

[0043] Preparation method: S1. Mix and boil the photoinitiator of the formulated amount and 1 / 3 of the reactive diluent of the formulated amount to obtain the photoinitiator mixed solution, which is set aside;

[0044] S2. Add the formula amount of polymer resin binder and 2 / 3 formula amount of reactive diluent into the stirring tank, disperse and stir at 800r / min for 30min to obtain the pre-prepared resin liquid, and the...

Embodiment 3

[0046] Embodiment 3, UV offset printing freezing point ink of the present invention and its preparation

[0047] Formula: polymer resin binder 460kg, reactive diluent 380kg, photoinitiator TPO 80kg, polytetrafluoroethylene wax powder 100kg and Lubrizol hyperdispersant 3250010kg.

[0048] The polymer resin binder is obtained by mixing polyketone resin, polyurethane acrylate resin and polyester acrylic resin in a weight ratio of 1:2.0:1.8.

[0049] The reactive diluent is obtained by mixing trimethylolpropane triacrylate and acryloyl morpholine in a weight ratio of 1:3.

[0050] Preparation method: S1. Mix and boil the photoinitiator of the formulated amount and 1 / 3 of the reactive diluent of the formulated amount to obtain the photoinitiator mixed solution, which is set aside;

[0051] S2. Add the formula amount of polymer resin binder and 2 / 3 formula amount of reactive diluent into the mixing tank, disperse and stir at 700r / min for 25min to obtain the pre-prepared resin liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com