Regulation method of high-temperature thermoelectricity Sr3Co4O9 thin-film electrical resistivity

A thin-film resistor and thermoelectric technology, which is applied in the manufacture/processing of thermoelectric devices, ion implantation plating, coating, etc., can solve the problems of high cost and complicated single crystal preparation process, and achieve the effect of continuous control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

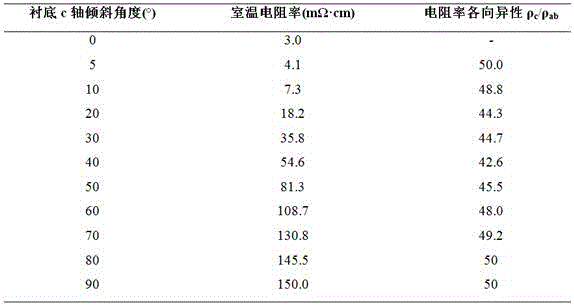

[0015] Pretreatment of c-axis tilted single crystal substrates: SrTiO with 0° tilt 3 (100) The single crystal substrate is annealed at 1000°C in the air atmosphere for 1 hour, and then treated with acetone, alcohol and deionized water in an ultrasonic cleaner at room temperature for 2 minutes each, and then annealed at 1000°C in the air atmosphere. 1h to obtain a single TiO 2 Termination layer, single crystal substrate with atomically smooth surface.

[0016] Epitaxial thin film growth: using pulsed laser deposition technology with KrF excimer laser with a wavelength of 248nm and a pulse width of 28ns as the light source, with a laser energy of 175mJ, a laser frequency of 3Hz, and a background vacuum of 1×10 -3 Pa, the substrate temperature is 780°C, and the flowing oxygen pressure is 30Pa as the growth process, and the pretreated SrTiO 3 Sr Growth on (001) Single Crystal Substrate 3 co 4 o 9 film, after which at 780°C and 1×10 4 In situ annealing under Pa static oxygen...

Embodiment 2

[0019] Pretreatment of c-axis tilted single crystal substrates: SrTiO with 5° tilt 3 (100) The single crystal substrate is annealed at 1000°C in the air atmosphere for 1 hour, and then treated with acetone, alcohol and deionized water in an ultrasonic cleaner at room temperature for 2 minutes each, and then annealed at 1000°C in the air atmosphere. 1h to obtain a single TiO 2 Termination layer, single crystal substrate with atomically smooth steps.

[0020] Epitaxial thin film growth: using pulsed laser deposition technology with KrF excimer laser with a wavelength of 248nm and a pulse width of 28ns as the light source, with a laser energy of 175mJ, a laser frequency of 3Hz, and a background vacuum of 1×10 -3 Pa, the substrate temperature is 780°C, and the flowing oxygen pressure is 30Pa as the growth process, and the pretreated SrTiO 3 Sr Growth on (001) Single Crystal Substrate 3 co 4 o 9 film, after which at 780°C and 1×10 4 In situ annealing under Pa static oxygen p...

Embodiment 3

[0023] Pretreatment of c-axis tilted single crystal substrates: SrTiO with 10° tilt 3 (100) The single crystal substrate is annealed at 1000°C in the air atmosphere for 1 hour, and then treated with acetone, alcohol and deionized water in an ultrasonic cleaner at room temperature for 2 minutes each, and then annealed at 1000°C in the air atmosphere. 1h to obtain a single TiO 2 Termination layer, single crystal substrate with atomically smooth steps.

[0024] Epitaxial thin film growth: using pulsed laser deposition technology with KrF excimer laser with a wavelength of 248nm and a pulse width of 28ns as the light source, with a laser energy of 175mJ, a laser frequency of 3Hz, and a background vacuum of 1×10 -3 Pa, the substrate temperature is 780°C, and the flowing oxygen pressure is 30Pa as the growth process, and the pretreated SrTiO 3 Sr Growth on (001) Single Crystal Substrate 3 co 4 o 9 film, after which at 780°C and 1×10 4 In situ annealing under Pa static oxygen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com