Low-temperature rapid freezing and freeze-drying system

A freeze-drying and low-temperature technology, which is applied in the direction of drying, drying solid materials, and drying solid materials without heating. It can solve the problems of reduced total installed power, extra energy consumption of the system, and inconvenient application, and achieves a large heat transfer coefficient. , miniaturization of equipment, high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

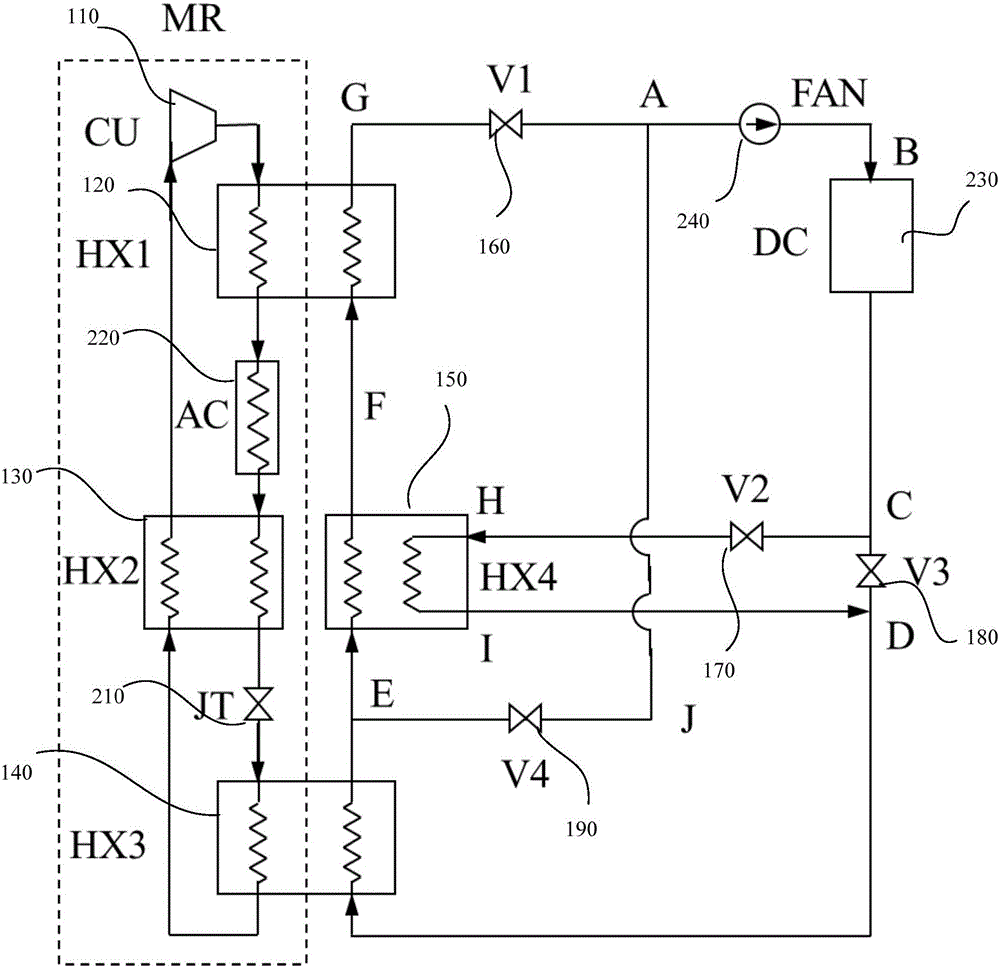

[0030] see figure 1 It is a schematic diagram of the structure of the ultra-low temperature quick freeze-drying system provided in Example 1 of the present invention for drying streptomycin drugs, and its working method is as follows:

[0031]When the refrigeration cycle system is turned on, the refrigerant enters the high-pressure refrigerant inlet of the first heat exchanger (HX1) 120 at the high-pressure refrigerant outlet of the compressor unit (CU) 110, and the high-pressure refrigerant of the first heat exchanger (HX1) 120 The outlet enters the inlet of the air cooler (AC) 220, enters the high-pressure refrigerant inlet connected to the second heat exchanger (HX2) 130 through the air cooler (AC) 220, and passes through the high-pressure refrigeration of the second heat exchanger (HX2) 130 The refrigerant outlet enters the refrigerant high-pressure inlet of the throttling element (JT) 210, and the refrigerant low-pressure outlet of the throttling element (JT) 210 enters t...

Embodiment 2

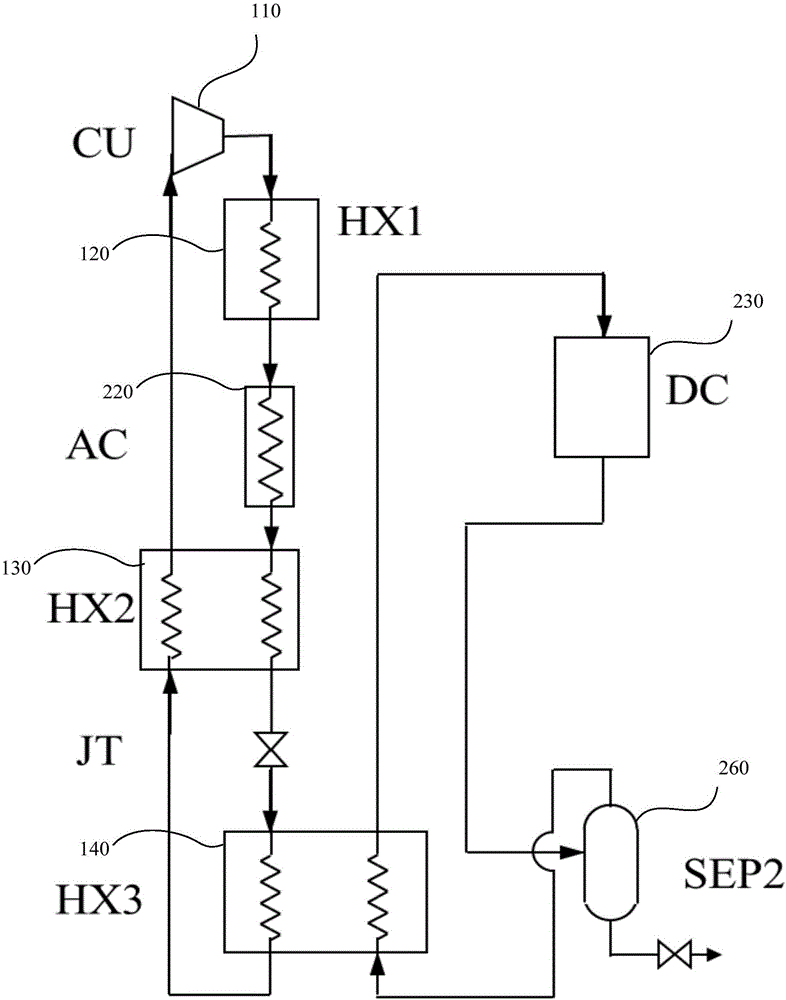

[0033] Such as figure 2 As shown, it is the quick-freezing / freeze-drying working mode provided by the second embodiment of the present invention, and its working mode is as follows:

[0034] The low-temperature and low-humidity air A1 passes through the circulation fan (FAN) 240 to form air B1, absorbs the moisture in the air B1 in the drying chamber (DC) 230 to form wet air C1, and the wet air C1 passes through the third valve (V3) 180 to form air D1, after gas-solid separation, and cooling from the third heat exchanger (HX3) 140 to form low-humidity low-temperature air E1, and to form low-temperature low-humidity air after passing through the fourth valve (V4) 190 A1 completes the quick-freezing / freeze-drying cycle: A→B→C→D→E→J→A.

[0035] It can be understood that since the saturated moisture content of air is 3.9×10-4g / kg at -80°C, the quick freezing / lyophilization cycle can remove most of the moisture, remove the remaining adsorbed moisture, and start the desorption dry...

Embodiment 3

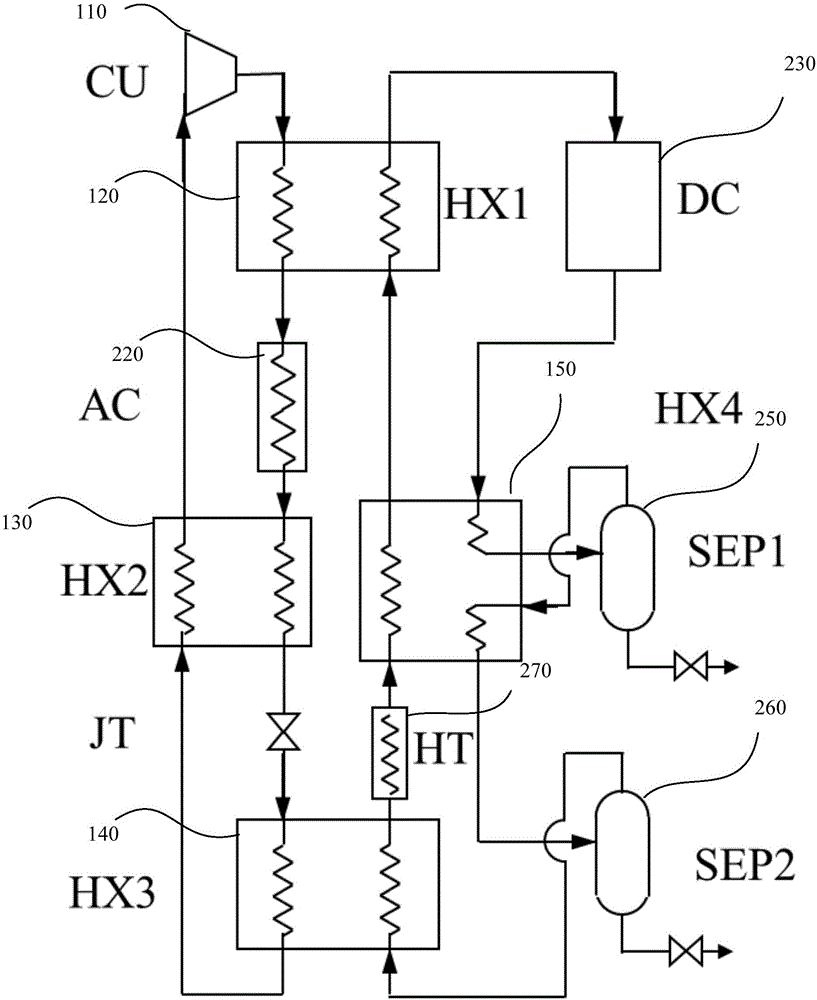

[0037] see image 3 , is the desorption drying working mode provided by Embodiment 3 of the present invention, and its working mode is as follows:

[0038] The air A2 at 40°C passes through the circulation fan (FAN) 240 to form B2, absorbs the bound water in the high-temperature air A2 in the drying chamber (DC) 230 to form humid air C2, and the humid air C2 passes through the second valve (V2) After 170, in the fourth heat exchanger (HX4) 150, complete the gas-water separation and cooling process of air state H to I and form air D2, and then form air D2 through the third heat exchanger (HX3) 140 to form air E2, the air E2 passes through the fourth heat exchanger (HX4) 150 to form air F, the air F passes through the first heat exchanger (HX1) 120 to form air G, and the air G passes through the first valve (V1) After 160°C, the high-temperature air A2 is formed to complete the desorption drying cycle, A→B→C→H→I→D→E→F→G→A, and complete the ultra-low temperature quick-freezing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com