Solid beverage composition containing lactoprotein and preparation method thereof

A solid beverage and composition technology, applied in dairy products, whey, applications, etc., can solve the problems of probiotics being destroyed, complex production process, protein denaturation, etc., to achieve the inhibition of enterotoxin production, simple production process, and lubricating intestinal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

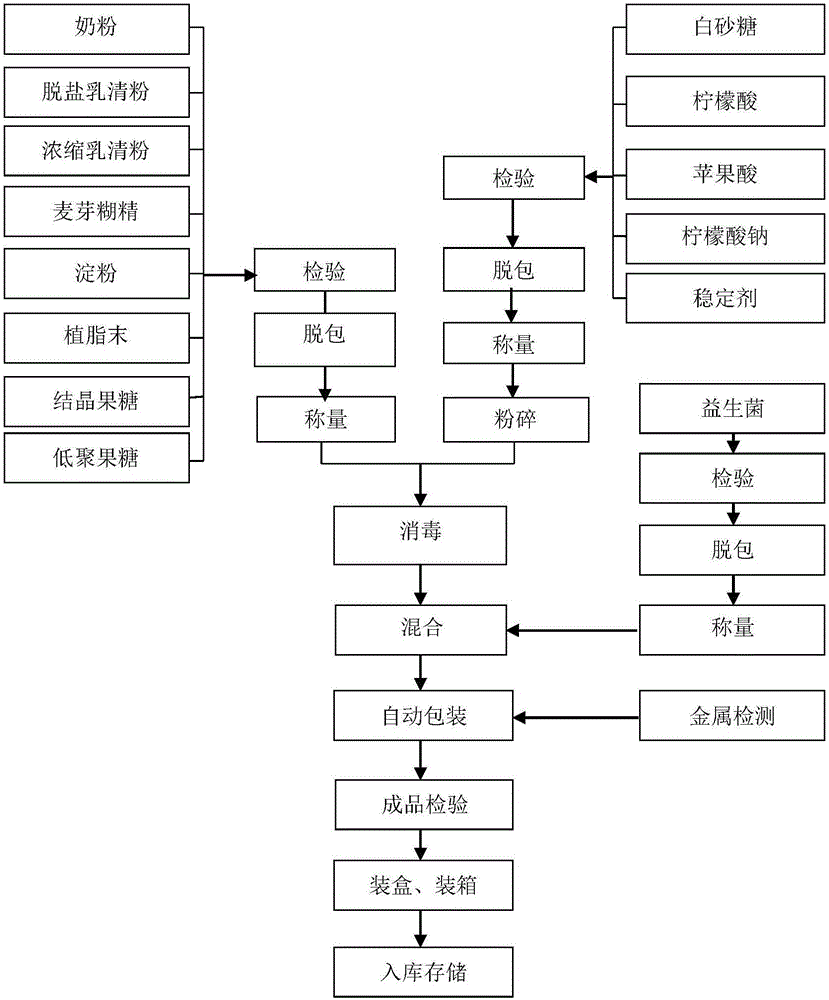

[0024] A preparation method of a milk protein-containing solid beverage composition, comprising the steps of:

[0025] A. Raw material mixing: the percentage by weight is milk powder 15%-25%; concentrated whey protein powder 10%-20%; white sugar 10%-20%; maltodextrin 10%-20%; desalted whey powder 10% -20%; starch 5%-15%; crystalline fructose 5%-15%; non-dairy creamer 5%-15%; stabilizer 1%-10%; citric acid 0.5%-5%; malic acid 0.5%-5 %; fructooligosaccharide 0.5%-5%; sodium citrate 0.5%-5% mixed according to the proportion to obtain the mixed powder;

[0026] B, disinfection: the mixed powder of step A is sterilized and sterilized to obtain the sterilized mixed powder;

[0027] C. Preparation of the composition: Add 0.025%-0.25% of probiotics to the sterilized mixed powder in step B, and mix uniformly to obtain a milk protein-containing solid beverage composition.

[0028] A further improvement is that the particle size of the white granulated sugar, citric acid, malic acid, s...

Embodiment 1

[0046] White granulated sugar, citric acid, malic acid, sodium citrate and stabilizer are respectively pulverized to a particle size of 70 mesh.

[0047] Raw material mixing: Weigh 15kg of milk powder; 10kg of concentrated whey protein powder; 10kg of white sugar; 10kg of maltodextrin; 10kg of desalted whey powder; 5kg of starch; kg; malic acid 0.5kg; fructooligosaccharides 0.5kg; sodium citrate 0.5kg according to the proportion of mixing, to obtain a mixed powder; disinfection: the mixed powder is sterilized by ultraviolet light for 8 hours, to obtain a sterilized mixed powder; preparation combination Product: add 0.025kg of probiotics to the sterilized mixed powder, mix the sterilized mixed powder and the probiotics in a mixing tank for 30 minutes, and mix evenly to obtain a milk protein-containing beverage composition.

[0048] When drinking, brew it with hot boiled water at about 70-80°C, and drink it after dissolving.

Embodiment 2

[0050] The white granulated sugar, citric acid, malic acid, sodium citrate and stabilizer are respectively pulverized to a particle size of 100 mesh.

[0051] Raw material mixing: Weigh 25kg of milk powder; 20kg of concentrated whey protein powder; 20kg of white sugar; 20kg of maltodextrin; 20kg of desalted whey powder; 15kg of starch; 15kg of crystalline fructose; 5kg of malic acid; 5kg of fructooligosaccharide; 5kg of sodium citrate was mixed according to the proportion to obtain a mixed powder; disinfection: the mixed powder was sterilized by ultraviolet light for 8 hours to obtain a sterilized mixed powder; preparation composition: to sterilize Add 0.25 kg of probiotics to the mixed powder, mix the sterilized mixed powder and the probiotics in a mixing tank for 30 minutes, and mix evenly to obtain a milk protein-containing beverage composition.

[0052] When drinking, brew it with hot boiled water at about 70-80°C, and drink it after dissolving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com