Coated zinc oxide with high stomach passing rate and preparation method of coated zinc oxide

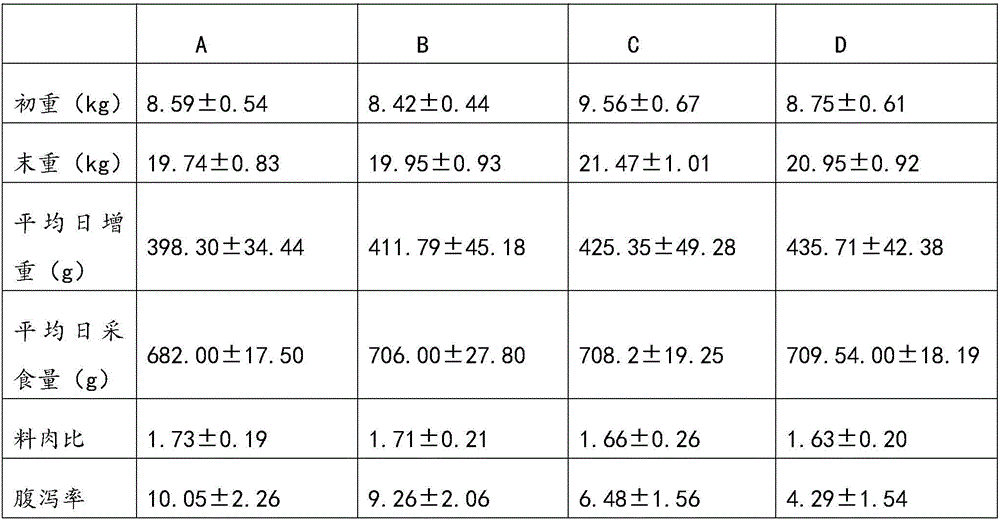

A zinc oxide and coating technology, which is applied in application, animal feed, additional food elements, etc., can solve problems such as failure to achieve the expected effect, low particle density, and intolerance to feed processing, etc., to improve physical damage resistance, melting point, etc. High, the effect of controlling diarrhea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Put 190kg of palm oil at 52°C, 15kg of hydrogenated vegetable oil, 40kg of palm wax, and 25kg of sorbitan fatty acid ester into a 500L reactor with a steam interlayer, heat it to 95°C with steam, stir continuously to dissolve it completely, and add 25kg of feed Grade zinc oxide, 5kg nano-zinc oxide, continue to keep warm at 85°C to 95°C, stir to form a uniform suspension. Release the molten liquid from the outlet, form a thin layer on the stainless steel plate, and blow cold air on the other side of the plate to make it quenched into a solid, and continue to cool at room temperature for 60 minutes. It is pulverized by a hammer mill, passed through a 20-mesh sieve, and the under-sieve is taken to obtain the finished product.

[0033] The process parameters of the reactor: the speed is 150 rpm, the steam temperature is 120°C;

[0034] The process parameters of the blower are: air flow, 2000m 3 / h;

[0035] The process parameters of the hammer mill are: speed 2800r / min....

Embodiment 2

[0037] Put 190kg of 52°C palm oil, 15kg of hydrogenated vegetable oil, 40kg of palm wax, and 25kg of sorbitan fatty acid ester into a 500L reaction kettle with a steam interlayer, heat it to 95°C, stir continuously to dissolve it completely, and add 25kg of feed grade zinc oxide , 5kg nano zinc oxide, continue to keep warm at 85 ℃ ~ 95 ℃, stir to make a uniform suspension. Move the molten liquid into the liquid storage tank at 90°C, stir and keep it warm, drop it into the flowing circulating cooling water from the dropping pill machine, take it out, blow off most of the surface water with a blower, dry it in air, pass through a 20-mesh sieve, and take the sieve to get the finished product .

[0038] The process parameters of the reactor: the speed is 150 rpm, the steam temperature is 120°C;

[0039] Process parameters of the dropping pill machine: porous dripper, the inner diameter of the dripper is 0.8mm, and the dripping speed of each hole is about 100 pills / min;

[0040] ...

Embodiment 3

[0042] Put 2.85kg 52℃ palm oil, 0.5kg hydrogenated vegetable oil, 0.5kg beeswax, 0.15kg sorbitan fatty acid ester, 6kg nano-zinc oxide in a hot kneader, heat to 85℃~95℃, and knead to form a uniform The soft material is moved into a swinging granulator for granulation, and the obtained granules are scattered and cooled by a blower, placed at room temperature for 60 minutes, then pulverized by a hammer mill, passed through a 20-mesh sieve, and the sieve is taken to obtain the finished product.

[0043] Thermal kneader process parameters:

[0044] The process parameters of the swing granulator are: drum speed 100r / min;

[0045] The process parameters of the blower are: air flow, 2000m 3 / h;

[0046] The process parameters of the hammer mill are: speed 2800r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com