Modified biochar material for removing arsenic, and preparation and application thereof

A biochar and biomass raw material technology, applied in the field of arsenic pollution treatment, can solve the problems of rare earth element lanthanum, such as high cost, unsuitable for popularization and utilization, complicated preparation process, etc. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

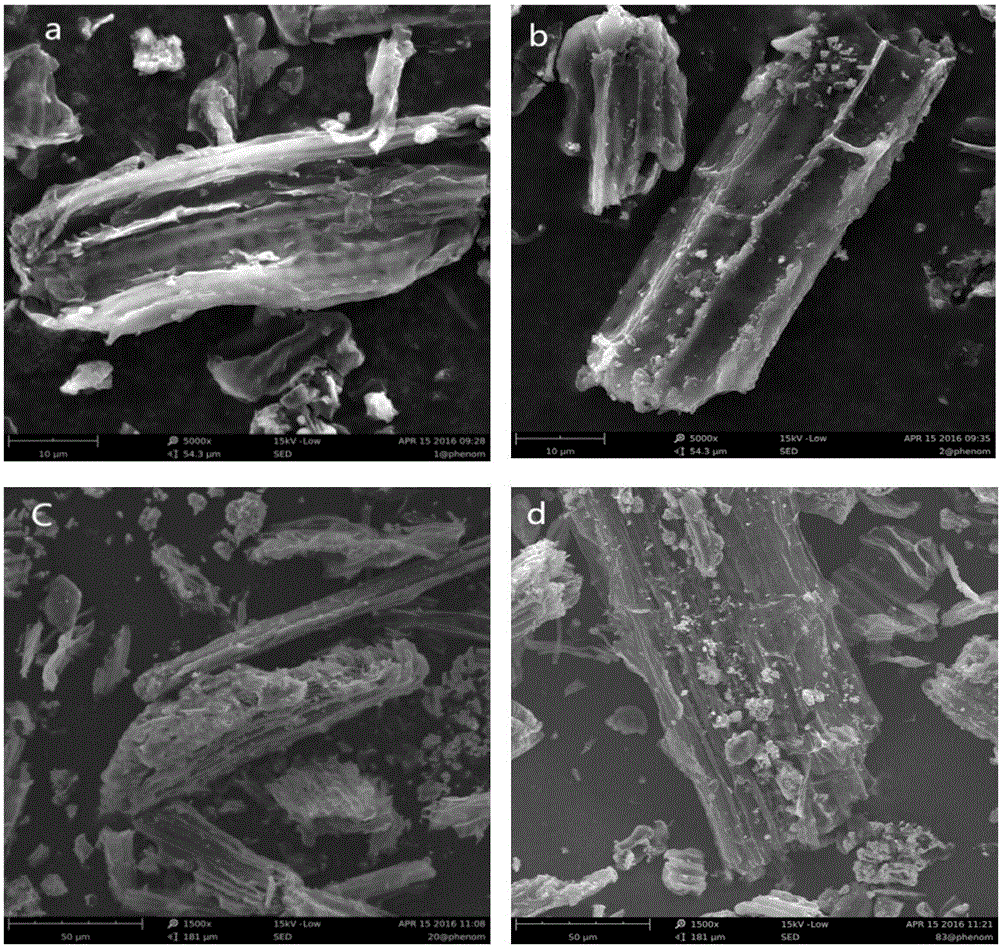

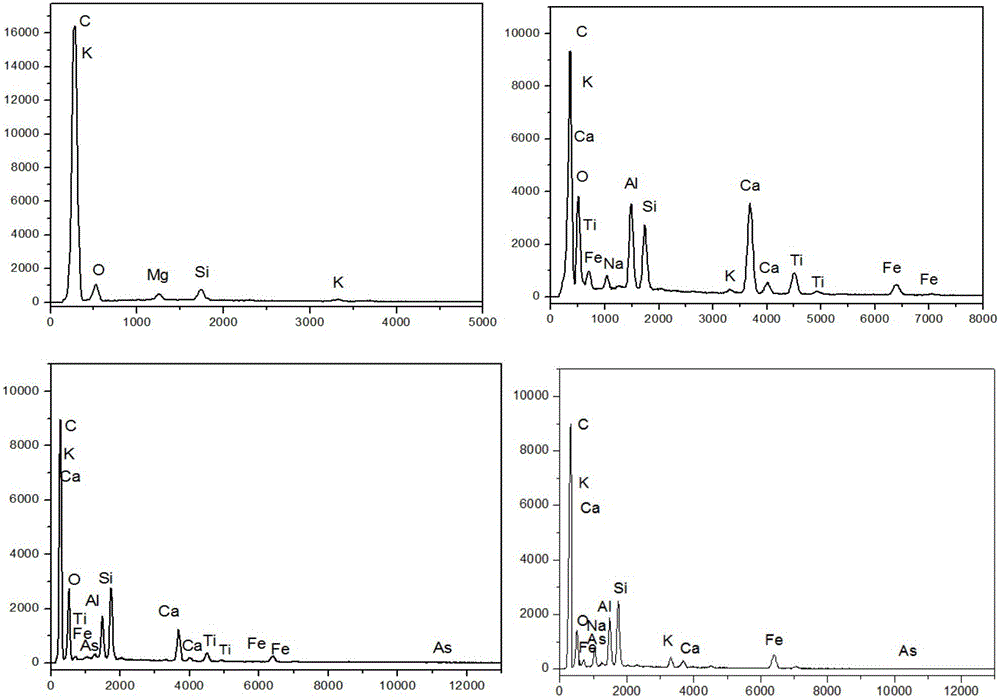

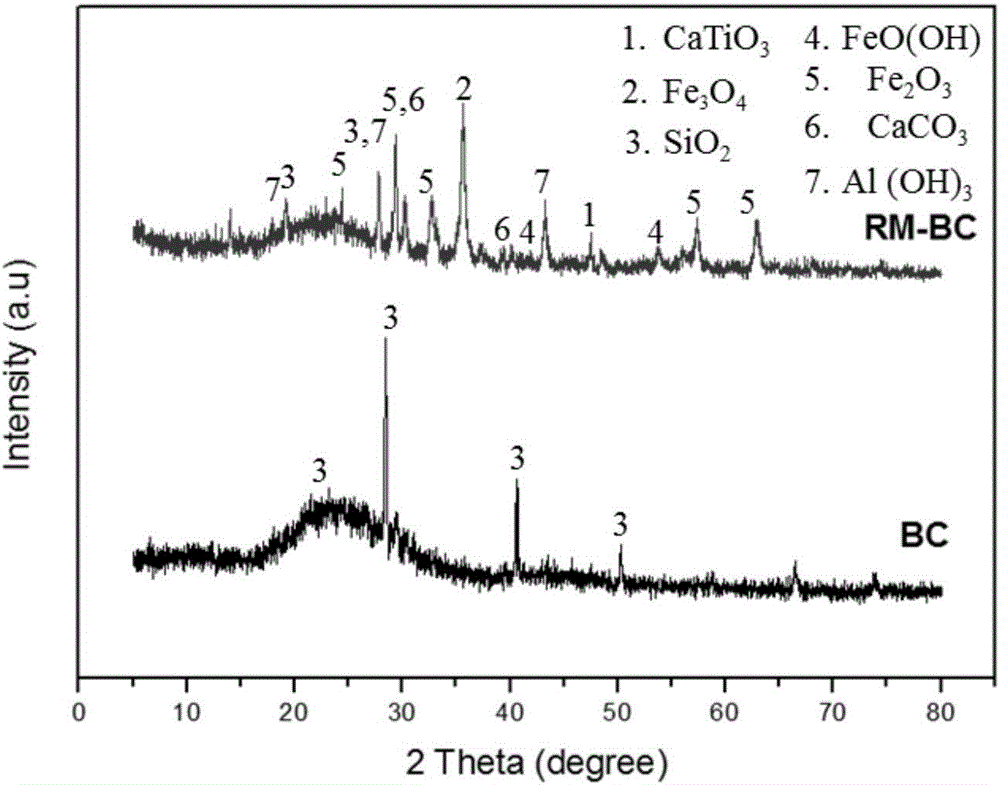

[0034] The red mud-based biochar material used for removing arsenic of the present embodiment is prepared by the following steps:

[0035] 1) Wash the rice straw to remove impurities, air-dry it, crush it, pass it through a 200-mesh sieve, and set it aside.

[0036] 2) Take a certain amount of red mud and add it to distilled water (the solid-to-liquid ratio of red mud and distilled water is 1:250g / mL), and apply ultrasonic waves for 1 hour to prepare a red mud suspension.

[0037] 3) Add the rice straw powder obtained in step 1) to the red mud suspension obtained in step 2), the mass ratio of rice straw to red mud is 5:1 (the red mud is calculated on a dry basis), stir well, and stir for 3 hours, Stand still and separate again, filter off the water.

[0038] 4) Put the product obtained in step 3) into a muffle furnace for anaerobic roasting, raise the temperature to 600°C at a heating rate of 5°C / min, keep at this temperature for 6h, cool to room temperature, and take out the...

Embodiment 2

[0065] This example is the effect of pH on the adsorption performance of unmodified biochar and red mud-based biochar on As(V) and As(III). The unmodified biochar and red mud-based biochar prepared in Example 1 were used.

[0066] Weigh 0.12g of unmodified biochar and red mud-based biochar into a 50mL centrifuge tube, then add 30mL of 10mg / L As(V) and As(III) solutions respectively, and use 0.1mol·L -1 Adjust the pH of the solution with HCl or NaOH to different pH values (2, 4, 6, 8, 10, 12), and place it in a constant temperature air shaker at room temperature (25±1°C) at a speed of 200rpm / min Shake for 24h. After the shaking was completed, it was filtered, and the concentration of arsenic in the filtrate was determined by atomic fluorescence.

[0067] Depend on Figure 4 .a It can be seen that when pH=2, red mud-based biochar adsorbs As(V) to the maximum adsorption capacity, and the adsorption capacity is 1622.51 μg·g -1 . When pH=6, the unmodified biochar adsorbed As...

Embodiment 3

[0069] This example is a fitting curve of kinetic adsorption of unmodified biochar and red mud-based biochar on As(V) and As(III). The unmodified biochar and red mud-based biochar prepared in Example 1 were used.

[0070] Weigh 0.12g of unmodified biochar and red mud-based biochar into a 50mL centrifuge tube, then add 30mL of 10mg / L As(V) and As(III) solutions respectively, and use 0.1mol·L -1 HCl or NaOH adjusted the optimal adsorption pH. Place in a constant temperature air shaker, and shake for different times (0.5, 1, 2, 4, 8, 12, 16 and 24h) at room temperature (25±1°C) at a speed of 200rpm / min. After the shaking was completed, it was filtered, and the concentration of arsenic in the filtrate was determined by atomic fluorescence.

[0071] Depend on Figure 5 It can be seen that the adsorption of As(V) and As(III) by unmodified biochar and red mud-based biochar reached equilibrium within 24 hours. Using pseudo-first-order and pseudo-second-order kinetics and Elovich m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com