Preparation method for Pt disk sub-micron electrode with controllable geometrical shape

A geometric shape and sub-micron technology, which is applied in the field of preparation of geometrically controllable Pt disk sub-micron electrodes, can solve the problems of poor controllability of micro-nano electrode tip morphology and geometric shape, increase of human factors, and inclination, etc. Achieve the effect of improving spatial resolution and dynamic detection limit, improving sensitivity, and sealing tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0036] The preparation method of the Pt disk submicron electrode of this example, its basic steps comprise:

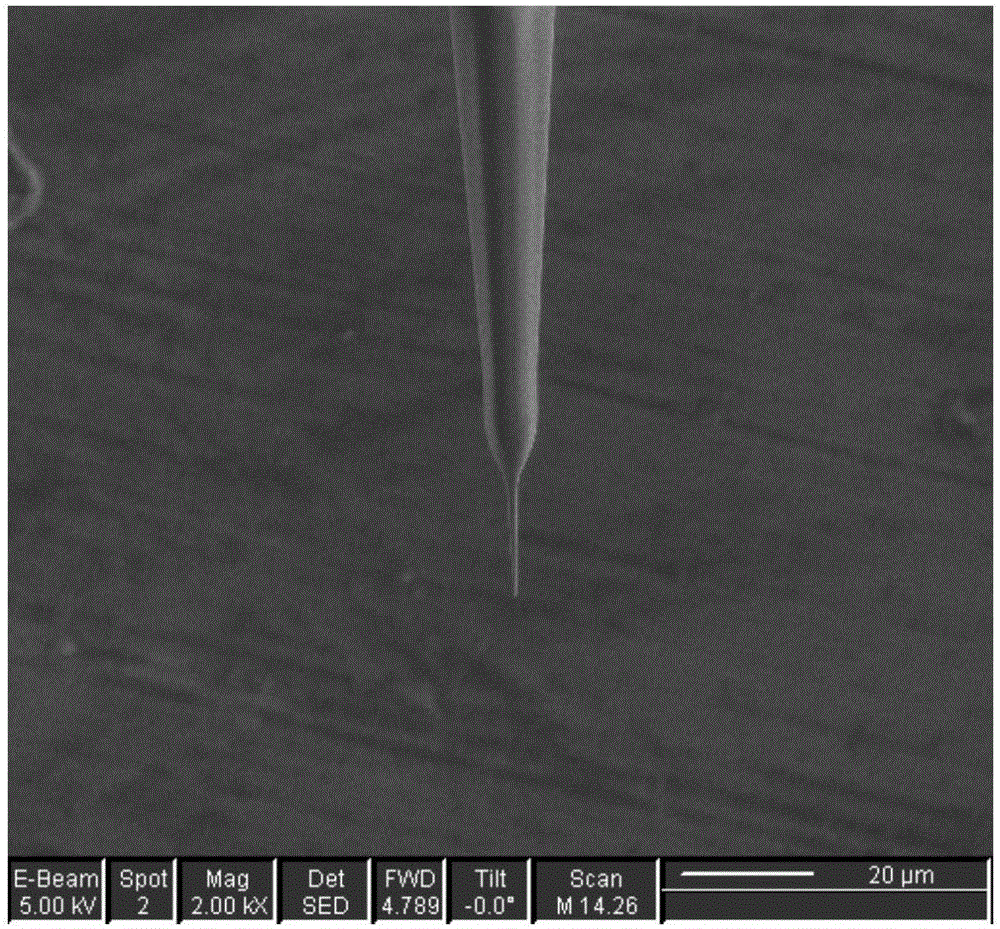

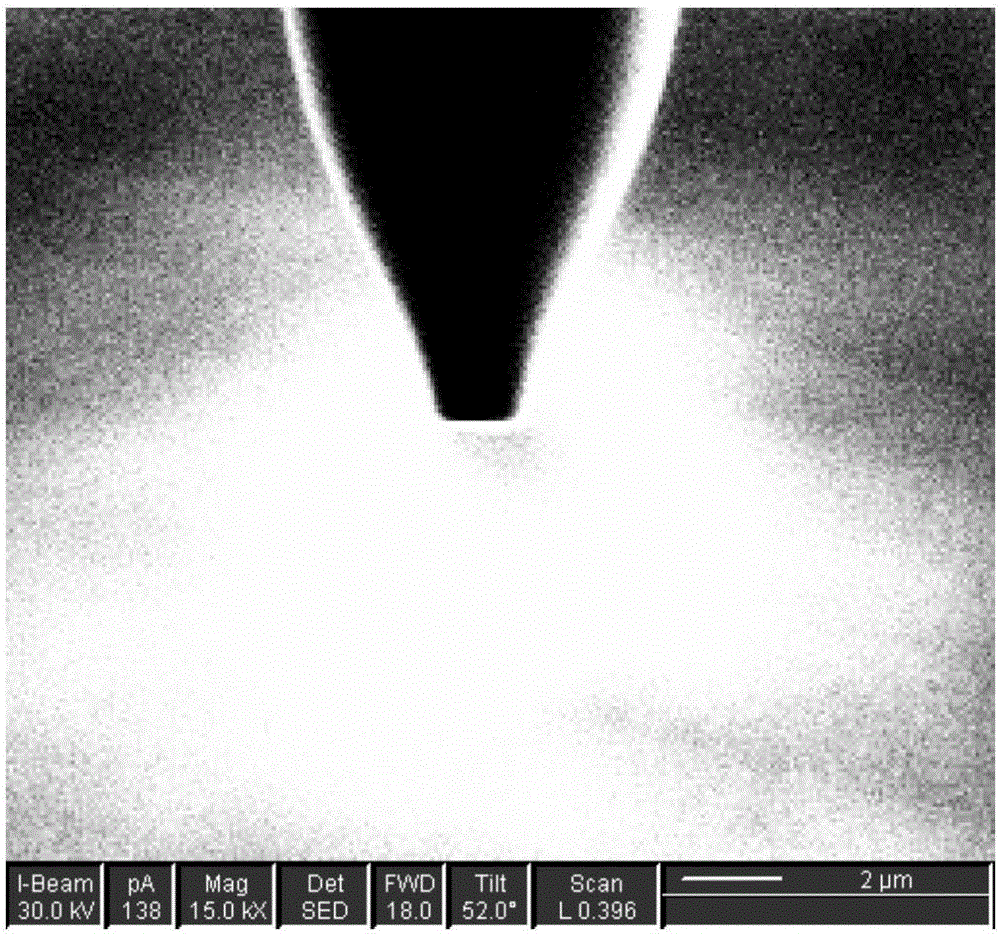

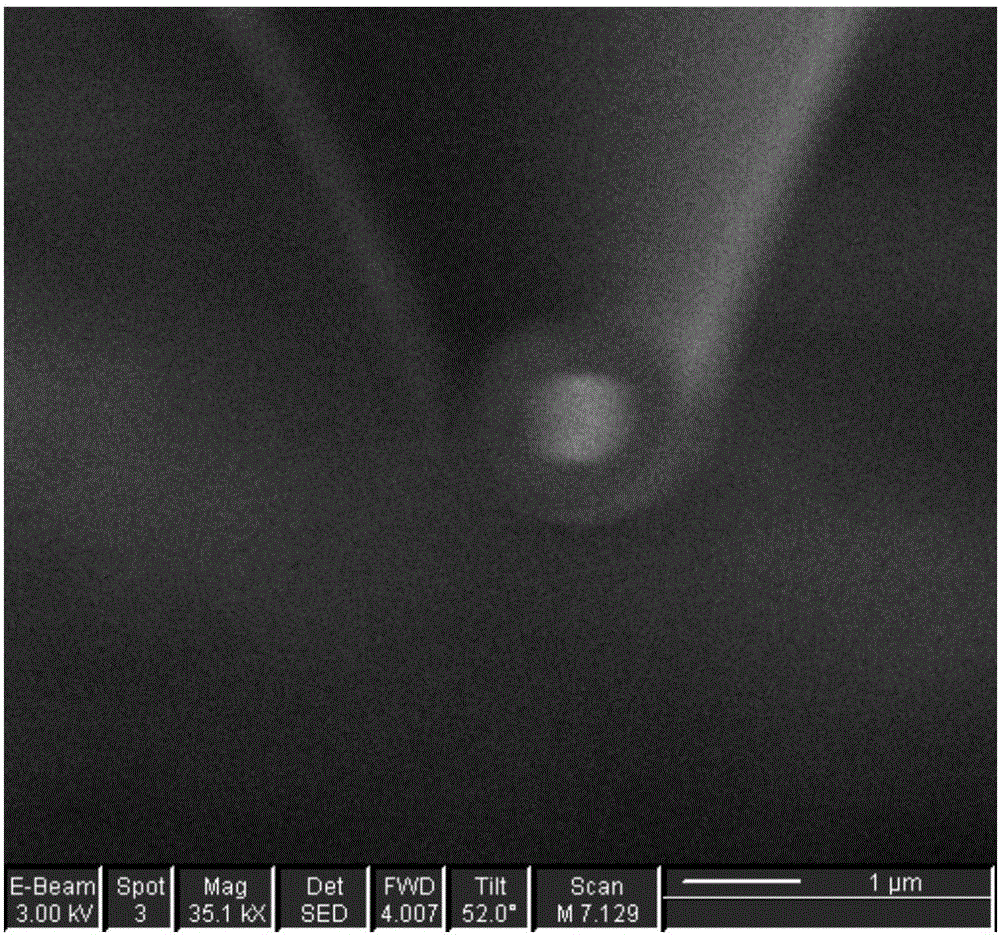

[0037] a. Take the Pt wire with a length of 1.5 cm and a diameter of 25 microns after annealing, and gently roll and straighten it by hand;

[0038] b. Take a boric acid capillary glass tube with an outer diameter of 1 mm, an inner diameter of 0.2 mm, and a length of 10 cm. 2 SO 4 with H 2 o 2 Soak and wash in a solution mixed with a volume ratio of 3:1 for 30 minutes, wash with deionized water for 3 times, and dry in an oven for later use;

[0039] c. placing the Pt wire in step a in the capillary glass tube in step b, and making the Pt wire in the middle of the capillary;

[0040]d. Seal one end of the capillary glass tube in step c with Parafilm, place it in the center of the Laser Puller P-2000 laser pulling instrument, and connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com