Preparation method and application of magnetic graphene oxide/chitosan adsorbent

A technology of oxidized rock and chitosan, which is applied in the fields of magnetic materials and environmental science, can solve problems such as biological hazards, and achieve rapid separation, simple methods, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

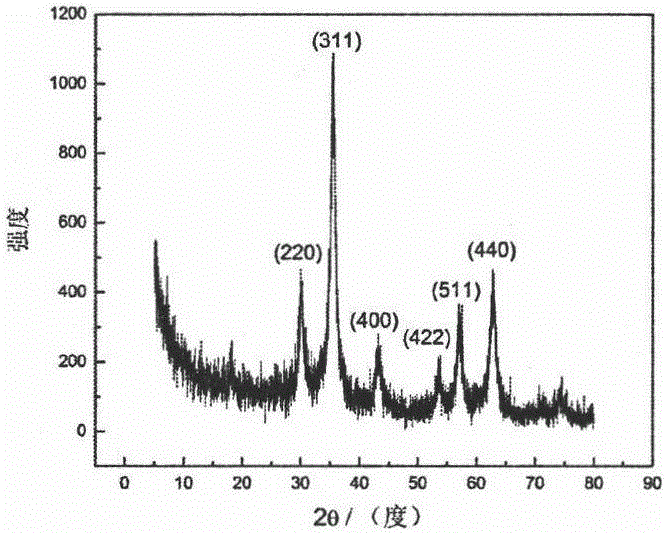

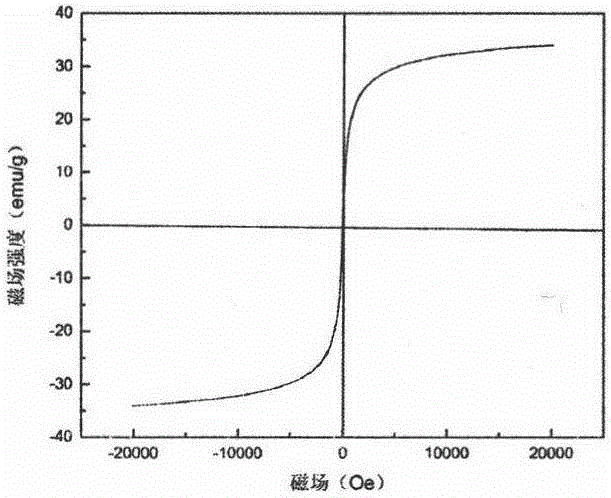

[0019] The graphite powder is oxidized into graphite oxide, and then ultrasonically exfoliated into graphene oxide. Add 1-15g of ferrous salt, 1-10g of ferric salt, 0.1-5g of graphene oxide, 50-500ml of distilled water in the beaker, sonicate in the ultrasonic device for 1-6 hours, then add NH 3 ·H 2 O to adjust the pH to 7-12, sonicate for 1-6h. Finally, the obtained product is washed to neutrality by the centrifugal separation method, and dried in a vacuum drying oven under the condition of 30-100° C., so as to obtain the magnetic graphene oxide composite material. Weigh 0.5-2g of the prepared magnetic graphene oxide and dissolve it in distilled water, ultrasonic 1-3h; add 0.5-3g chitosan (CS) in glacial acetic acid solution (2%) and ultrasonic 1-3h; take 10- Mix 100ml of magnetic graphene oxide solution and 10-100ml of CS solution, and sonicate; then add 50% glutaraldehyde to the solution, and continue to sonicate; prepare NaOH solution, adjust the pH of the above solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com