Organic negative electrode material of potassium ion battery and preparation method of organic negative electrode material

A technology of organic negative electrode and negative electrode material, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of few negative electrode materials, potential safety hazards, easy formation of dendrites, etc., and achieve high specific capacity, stable structure, and high Coulombic efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of an organic negative electrode material for a potassium ion battery, comprising the following steps:

[0035] (1) Weigh 2 g of terephthalic acid with a purity of 99% and 3.05 g of analytically pure KOH, and then add them to a flask filled with 40 mL of deionized water, and stir for 1 h with a magnetic stirrer;

[0036] (2) Transfer the reaction solution obtained in step (1) into a polytetrafluoroethylene liner, seal it in a reaction kettle, and react at 110° C. for 72 hours;

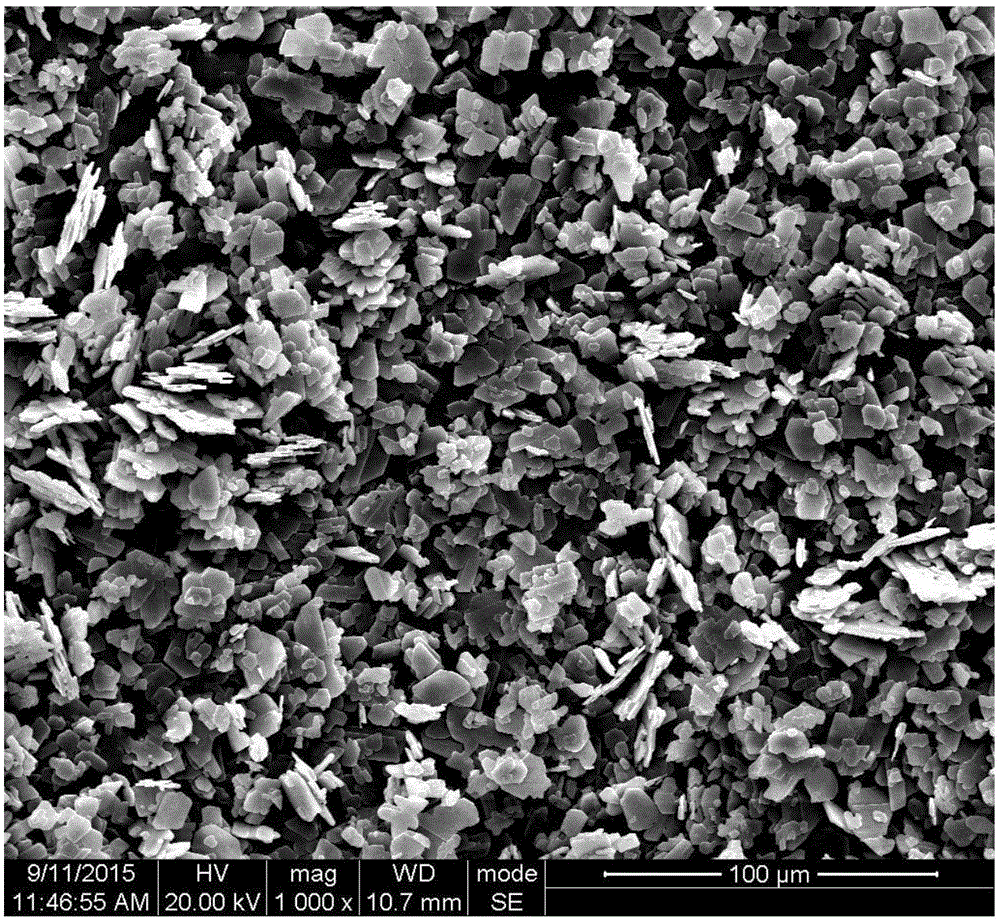

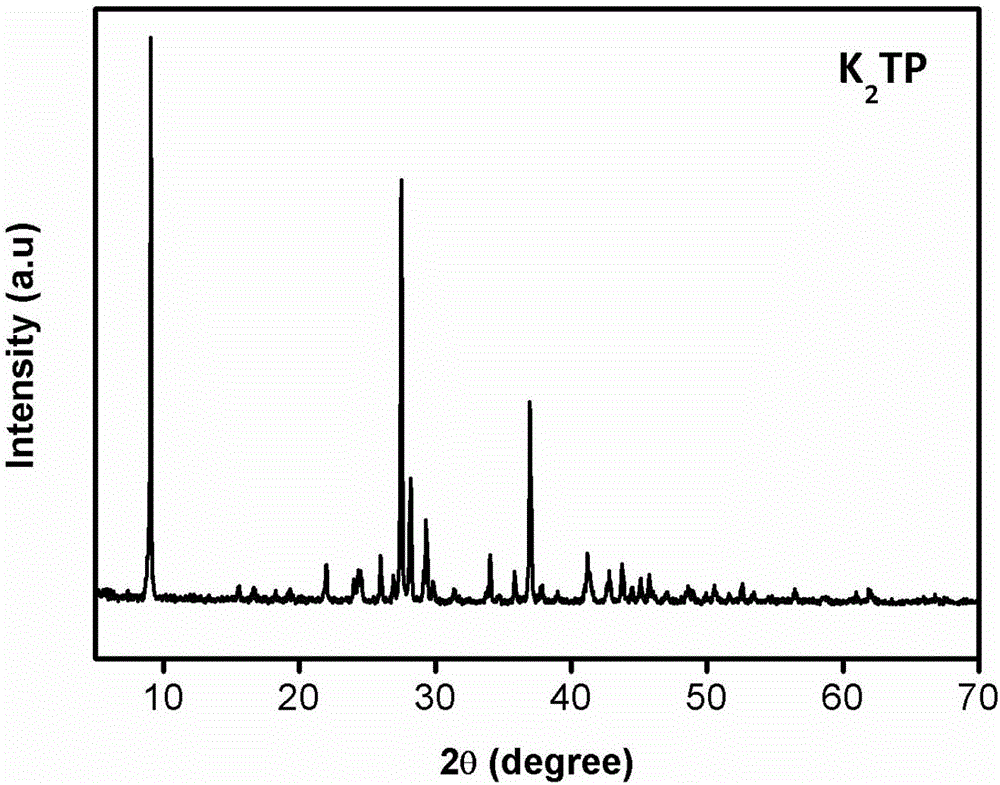

[0037] (3) Measure 20 mL of the reaction product obtained in step (2), add 50 mL of absolute ethanol to obtain a white precipitate, then centrifuge, wash with deionized water for more than 3 times, dry the obtained solid at 60 ° C for 8 h, and then dry it at 110 ° C Vacuum-dried for 6 hours to obtain an organic potassium terephthalate negative electrode material.

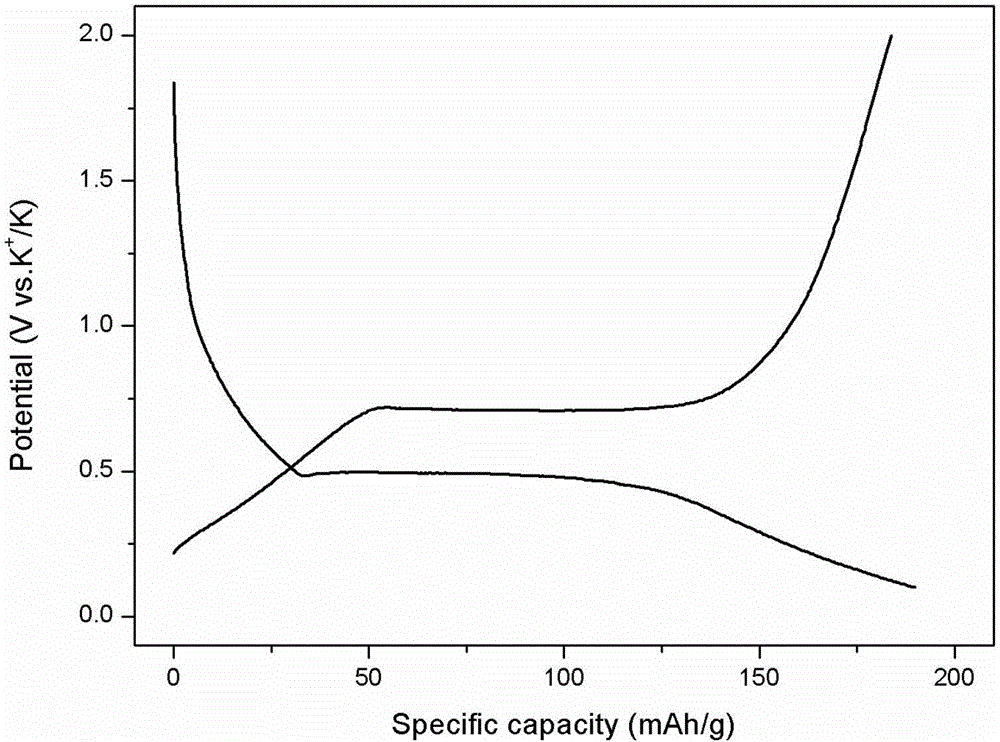

[0038] Potassium terephthalate (K 2 TP) as a potassium ion anode material, its reversible deintercalation mec...

Embodiment 2

[0047] A preparation method of an organic negative electrode material for a potassium ion battery, comprising the following steps:

[0048] (1) Weigh 2 g of pyridine-2,5-dicarboxylic acid with a purity of 99% and 3.05 g of analytically pure KOH, mix them, then add them to a flask filled with 40 mL of deionized water, and stir for 1 h with a magnetic stirrer;

[0049] (2) Transfer the reaction solution obtained in step (1) into a polytetrafluoroethylene liner, seal it in a reaction kettle, and react at 110° C. for 72 hours to obtain a clear solution;

[0050] (3) Measure 20 mL of the reaction product obtained in step (2), add 50 mL of absolute ethanol to obtain a white precipitate, then centrifuge, wash with deionized water for more than 3 times, dry the obtained solid at 80 ° C for 6 h, and then dry it at 120 ° C Dry in vacuum for 6h to get potassium pyridine-2,5-dicarboxylate (K 2 C 7 h 3 NO 4 ) anode material.

[0051] Potassium pyridine-2,5-dicarboxylate is used as a n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com