Clamp applied to plane polishing of front blade surfaces of hard alloy blades

A technology of cemented carbide inserts and rake faces, which is applied in the direction of grinding workpiece supports, etc., which can solve the problems of small surface area of cemented carbide inserts, affecting the consistency of the polishing quality of the rake face, and affecting the polishing quality of the rake face. , to achieve the effect of improving processing quality, improving polishing accuracy, and fast clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

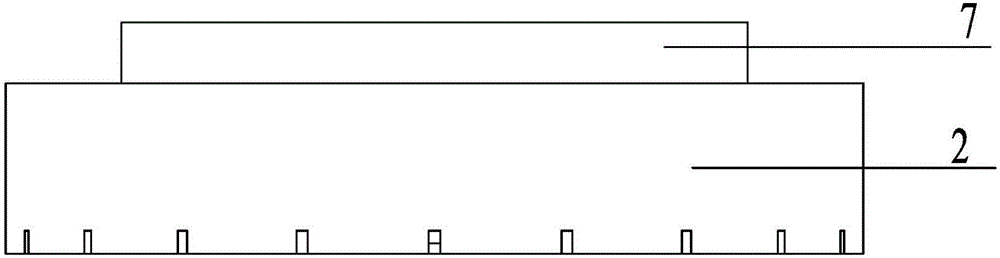

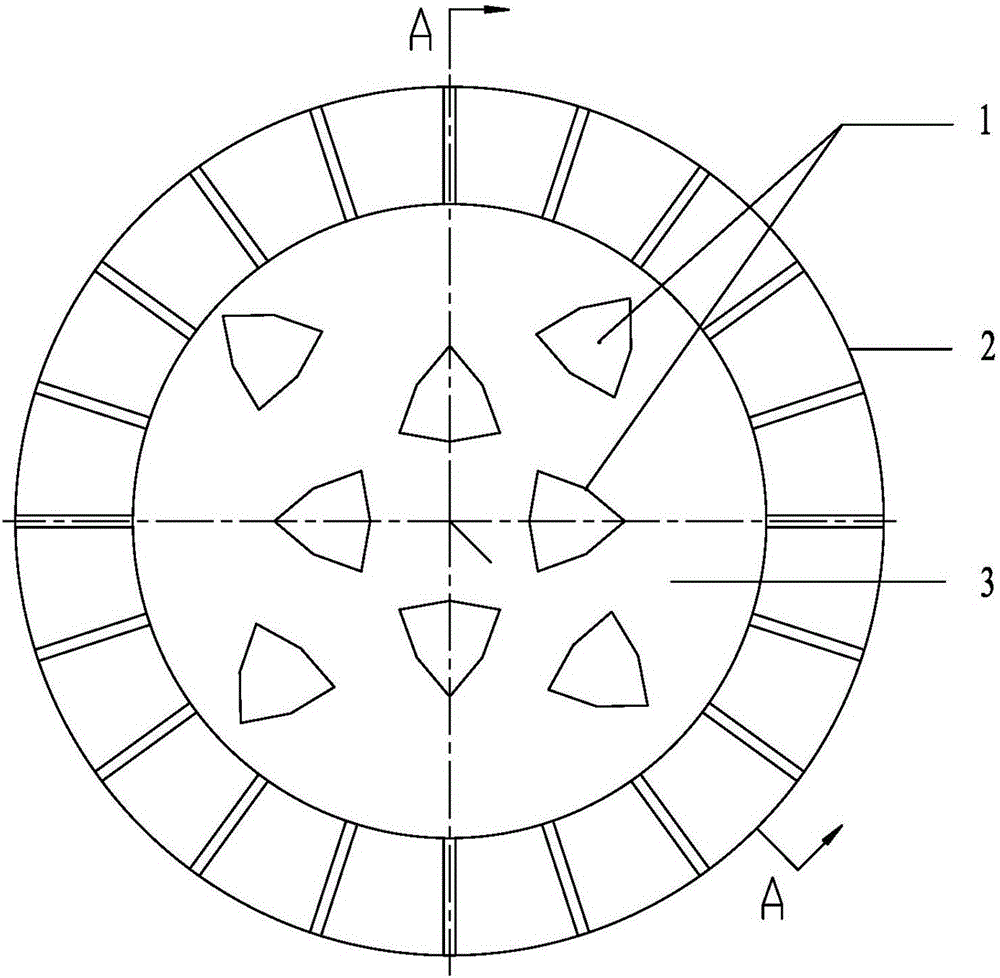

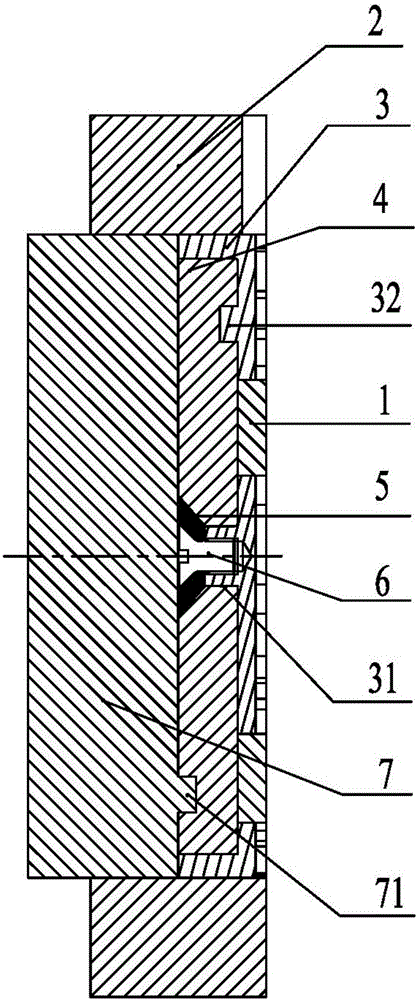

[0034]This embodiment provides a fixture for the rake face of a plane polished cemented carbide insert, such as figure 1 , 2 , 3, including the fixed ring 2, the blade chucking disc 3 and the magnet 4, the magnet 4 is installed and fixed in the blade chucking disc 3, the blade chucking disc 3 is installed in the fixing ring 2, the lower surface of the blade chucking disc 3 A blade installation hole matching the shape of the cemented carbide blade 1 is arranged on the top, and the depth of the blade installation hole is smaller than the thickness of the cemented carbide blade 1 .

[0035] The fixture of the rake face of the planar polished cemented carbide insert provided in this embodiment, the cemented carbide insert that can be processed is: the rake angle is 0°, the rake face does not have a chip breaker, and the bonding phase in the insert material can be Cobalt (Co) and Nickel (Ni) attracted by a magnet. A magnet 4 is installed and fixed in the blade chucking disc 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com