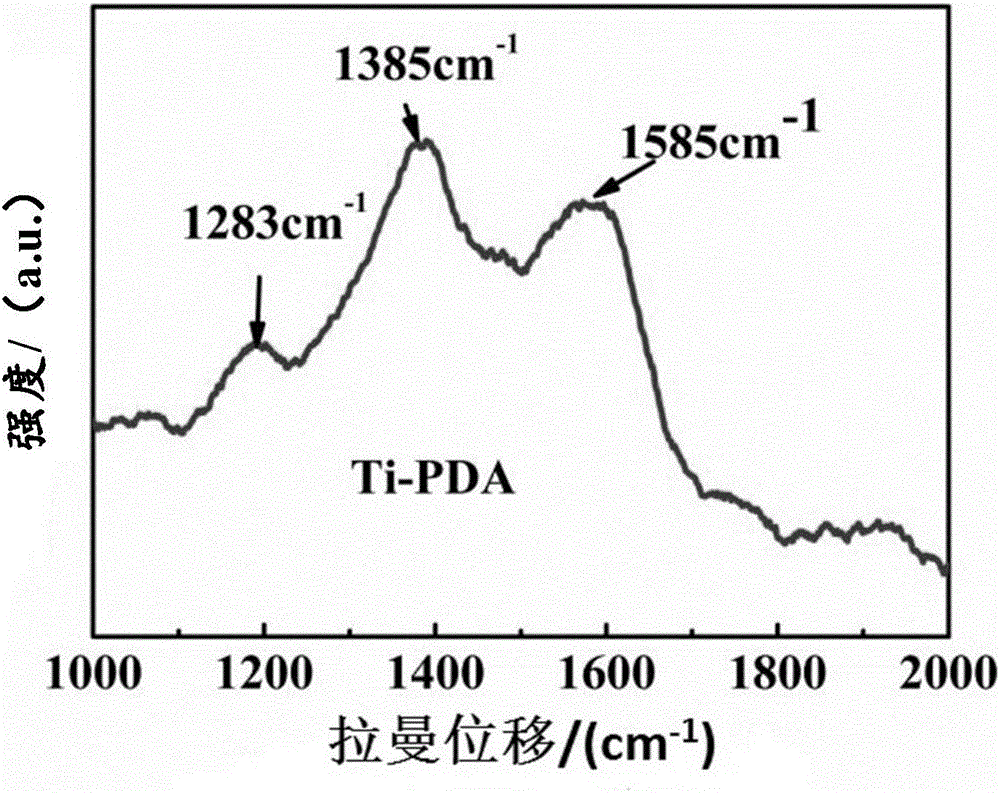

Preparation method and application of titanium surface polydopamine film

A technology of polydopamine film and dopamine, which is applied in the field of polydopamine film preparation, can solve the problems that polydopamine film cannot grow indefinitely, the degree of polymerization of dopamine is low, and affects the polymerization speed, etc., and achieves good hydrophilicity and anti-oxidation performance. Simple, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of polydopamine film on titanium surface, comprising:

[0027] S1) adjusting the pH value of the dopamine solution to neutral or weakly acidic with a weak acid to obtain a reaction solution;

[0028] S2) providing a three-electrode system, using the titanium substrate as the working electrode, and making one side of the titanium substrate contact the reaction solution;

[0029] S3) Connect the three-electrode system to a voltage, and construct a polydopamine film on the surface of the titanium substrate by cyclic voltammetry.

[0030] Wherein, the present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0031] In the present invention, the dopamine solution is a dopamine solution well known to those skilled in the art, and there is no special limitation. In the present invention, it is preferably a mixed solution of dopamine and tris (Tris) bu...

Embodiment 1

[0049] 1.1 Treatment of titanium substrate:

[0050] Medical pure titanium pretreatment: The medical pure titanium sheet with a diameter of 10 mm and a thickness of 0.1 mm was ultrasonically cleaned with acetone, absolute ethanol and deionized water in an ultrasonic machine for 10 minutes; then HF (concentration 0.54 mol / L) and HNO 3 (concentration 0.29mol / L) mixed acid was prepared according to the volume ratio of 1:1 to soak the titanium sheet, and finally ultrasonically cleaned with deionized water for 5-15min, blown dry with nitrogen and placed in a desiccator for later use to obtain acid pretreated Titanium sheet (pTi).

[0051] Spraying gold on the surface of the titanium sheet: using gold as the target material, pTi is vacuumed and sputtered for 120 s, rinsed with deionized water for 3 to 5 times, blown dry with nitrogen, and placed in a desiccator for later use to obtain pTi-Au.

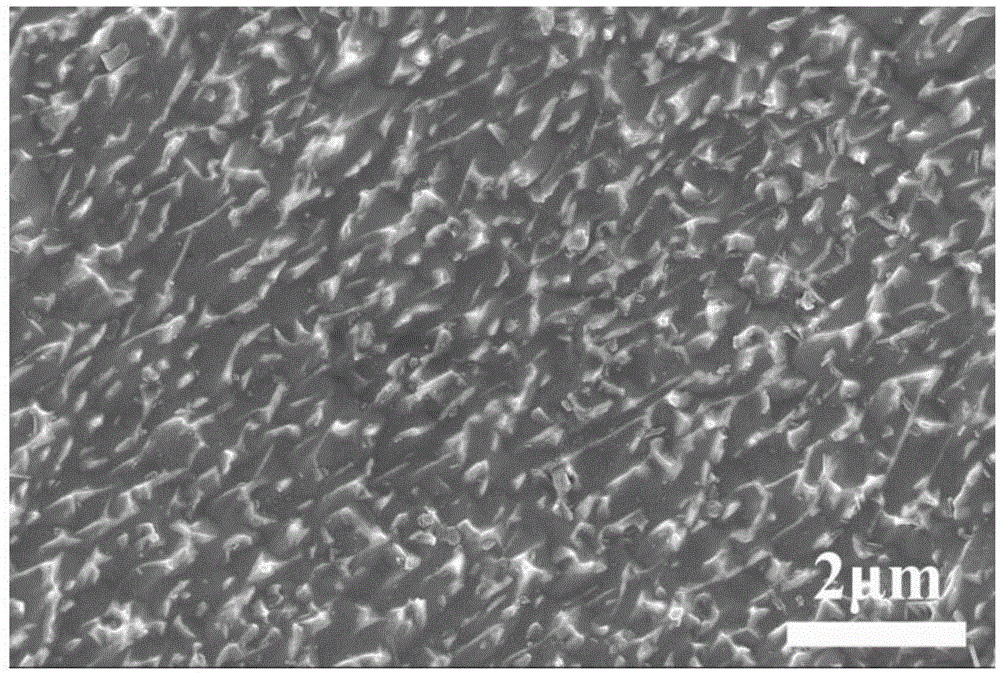

[0052] 1.2 Construction of polydopamine film layer on the surface of titanium sheet:

...

Embodiment 2

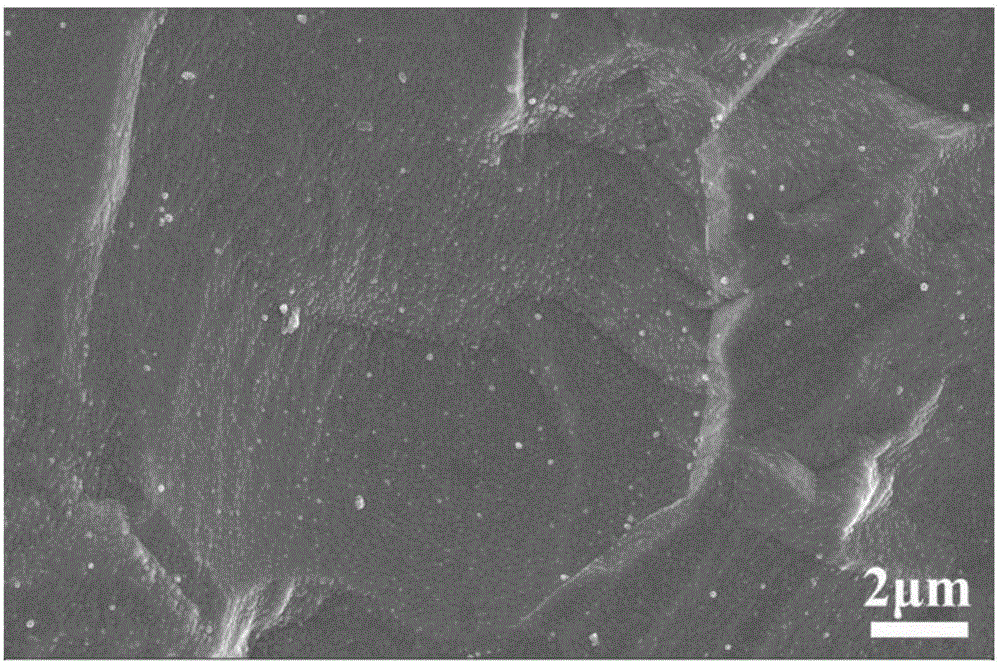

[0060] 2.1 The treatment of the titanium substrate is the same as 1.1 in Example 1.

[0061] 2.2 Construction of polydopamine film layer on the surface of titanium sheet:

[0062] Consistent with the steps in 1.2 in Example 1, except that the conditions used when constructing the dopamine membrane were changed to a cycle potential range of -1.0 to +1.0V; a cycle scan rate of 20mV / s; a resting time of 10s; cycle 20 times .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com