Preparation method and application of polycyclotriphosphazen porous material

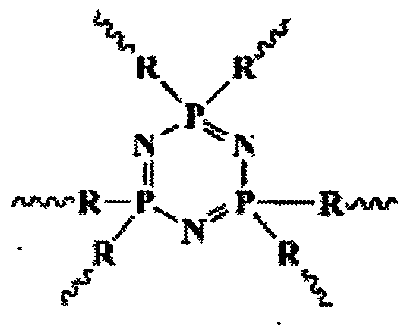

A porous material, polycyclic phosphazene technology, applied in the field of preparation of polycyclic phosphazene porous materials, can solve the problems of lowering the ignition point of impregnated activated carbon, lower adsorption efficiency, secondary pollution, etc., and achieve good molecular thermal stability and low regeneration consumption The effect of low energy and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

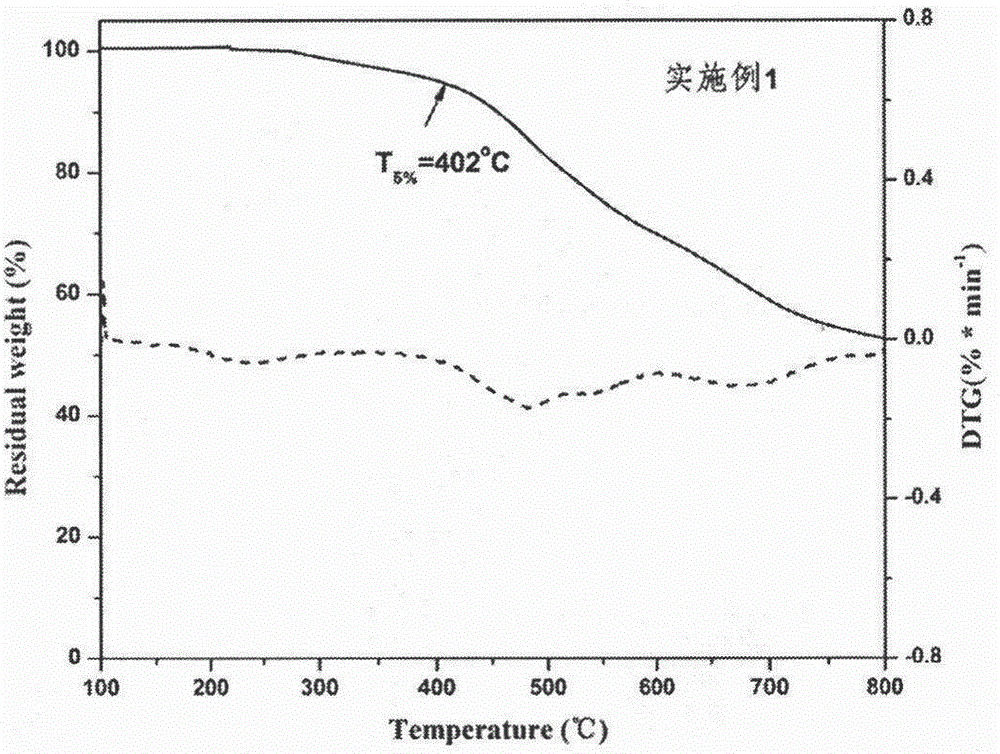

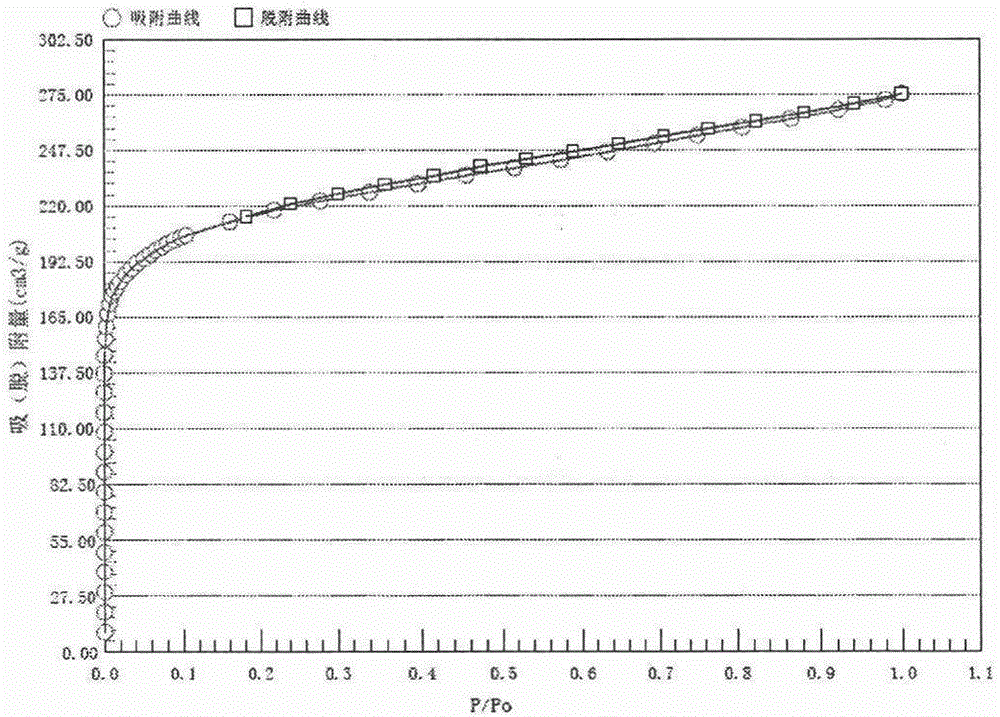

Embodiment 1

[0033] Equipped with mechanical stirring, reflux condenser and constant pressure dropping funnel, thermometer, N 2 Into the 500mL five-neck round-bottomed flask of the introduction tube, add 300mL of acetonitrile, 3.47g (0.01mol) of hexachlorocyclotriphosphazene, and 5.16g (0.06mol) of piperazine in sequence, and after stirring evenly, slowly add 30mL of triethylamine dropwise, N 2 After reacting at 50°C for 24 hours under protection, the filtrate was removed by filtration, washed with water for 3 times and dried to obtain a cyclic phosphazene polymer. Finally, under vacuum conditions (0.1mmHg), heated to 200°C for 12 hours to obtain a polycyclic phosphine Nitrile porous material. After testing, the specific surface area of the porous material is 1067m 2 / g, the average pore size is 2.1nm, CO 2 The adsorption capacity is 15.1 wt% (298K, 1 bar), and the adsorption capacity of iodine vapor is 90.5 wt% (333K).

Embodiment 2

[0035] Equipped with mechanical stirring, reflux condenser and constant pressure dropping funnel, thermometer, N 2 Into the 500mL five-necked round-bottomed flask with the introduction tube, add 250mL of tetrahydrofuran, 3.47g (0.01mol) of hexachlorocyclotriphosphazene, and 13.44g (0.08mol) of 4,4-dipiperidine in sequence. After stirring evenly, slowly add Pyridine 50mL, N 2 After reacting at 45°C for 48hrs under protection, the filtrate was removed by filtration, washed with water for 3 times and then dried to obtain a cyclic phosphazene polymer. Finally, under vacuum conditions (0.1mmHg), heated to 180°C for activation for 24hrs to obtain a polycyclic phosphazene porous material. After testing, the specific surface area of the porous material is 1244m 2 / g, the average pore size is 1.8nm, CO 2 The adsorption amount is 17.3wt% (298K, 1bar), the iodine vapor adsorption amount is 102.1wt% (333K), and the iodine adsorption amount in n-hexane solution is 84mg / g (295K, 4hr) ...

Embodiment 3

[0037] Equipped with mechanical stirring, reflux condenser and constant pressure dropping funnel, thermometer, N 2 Into the 500mL five-neck round-bottomed flask of the introduction tube, add 400mL of acetone, 3.47g (0.01mol) of hexachlorocyclotriphosphazene, 1H,1'H-7,7'-bipyrimidine[4,5-b]pyridine 2.36g (0.1mol), after stirring evenly, slowly add lithium carbonate 5g, N 2 After reacting at 60°C for 12 hours under protection, remove the filtrate by filtration, wash with water for 3 times, and then dry to obtain the cyclic phosphazene polymer. Finally, under vacuum conditions (0.1mmHg), heat to 150°C for activation for 48 hours to obtain the polycyclic phosphazene porous material. After testing, the specific surface area of the porous material is 1419m 2 / g, the average pore size is 1.6nm, CO 2 The adsorption capacity is 18.9wt% (273K, 1bar), CO 2 The adsorption capacity is 12.8 wt% (298K, 1 bar).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com