Anti-pollution-flashover superhydrophobic paint, and preparation method and application thereof

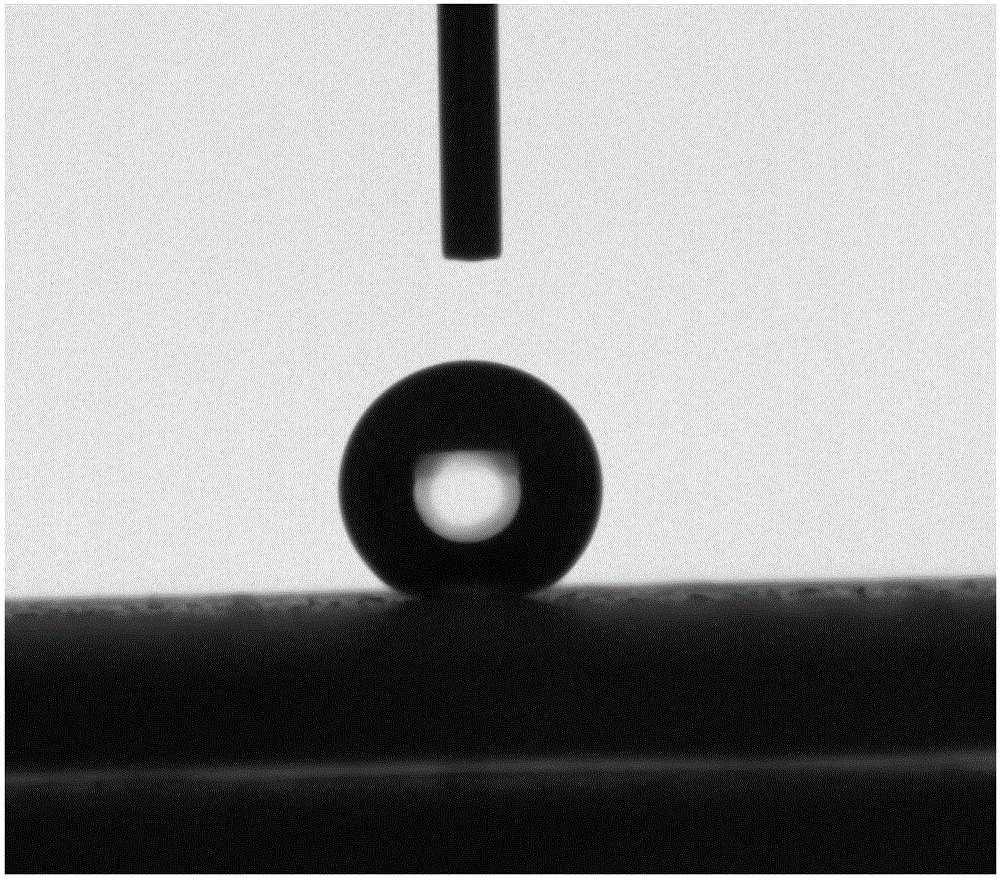

A super-hydrophobic coating and anti-pollution flashover technology, applied in the field of coatings, can solve problems such as accelerating the process of dirty wetting, increasing the accumulation of pollution on the surface of power equipment, and reducing the safety level of external insulation of power transmission and transformation equipment, achieving good self-repair effect, The effect of ensuring long-term working performance and excellent water-repellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

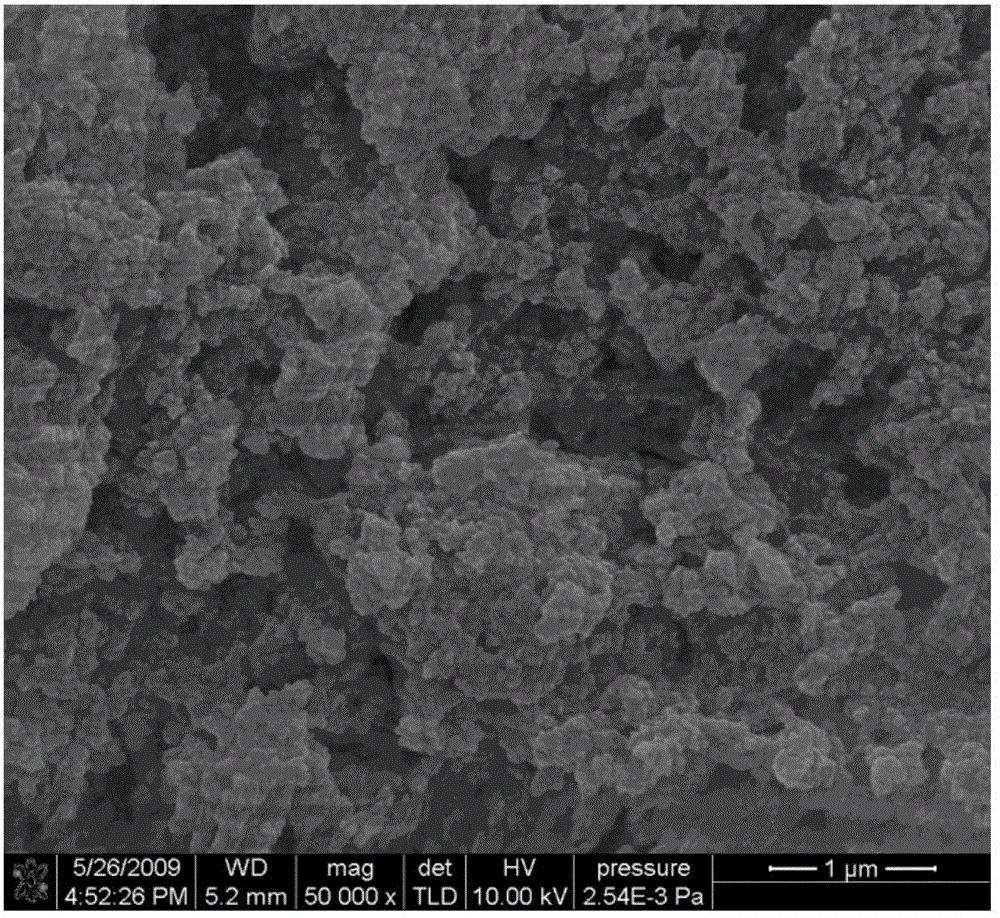

[0028] (1) According to the mass ratio of nano-silica particles, polydimethylsiloxane and n-heptane to 4:40:10, add nano-silica particles to n-heptane containing polydimethylsiloxane After stirring mechanically at 100r / min for 15 minutes in alkanes, ultrasonication was performed at an ultrasonic frequency of 1kHz for 5 minutes to disperse the nano-silica particles evenly, and after the n-heptane was volatilized, nano-silica particles with low surface energy were obtained. Wherein, the n-heptane containing polydimethylsiloxane is prepared by mixing dimethylsiloxane and n-heptane and mechanically stirring at 100 r / min for 10 minutes.

[0029] (2) The mass ratio of the low surface energy nano-silicon dioxide particles, polyvinylidene chloride and acetone prepared in step (1) is 1:5:2, and after the three are mixed, they are mixed at 70°C with 100r / min mechanically stirred for 50min to prepare an antifouling flashover superhydrophobic coating.

Embodiment 2

[0031] (1) According to the mass ratio of nano-silica particles, polydimethylsiloxane and ethanol, the mass ratio of the three is 8:35:8, the nano-silica particles are added to the alcohol containing polydimethylsiloxane, After mechanical stirring at 200r / min for 15 minutes, ultrasonication was performed at an ultrasonic frequency of 1.25kHz for 7 minutes to uniformly disperse the nano-silica particles, and after the ethanol volatilized, nano-silica particles with low surface energy were prepared. Wherein, the ethanol containing polydimethylsiloxane is prepared by mixing dimethylsiloxane and ethanol and mechanically stirring at 200 r / min for 15 minutes.

[0032] (2) The mass ratio of the low surface energy nano-silica particles, epoxy resin and methyl ethyl ketone prepared in step (1) is 2:4:1.5. / min mechanically stirred for 60min to prepare an antifouling flashover superhydrophobic coating.

Embodiment 3

[0034] (1) The mass ratio of nano-silica particles, polydimethylsiloxane and acetone is 12:30:5, and the nano-silica particles are added to the acetone containing polydimethylsiloxane, After mechanical stirring at 200 r / min for 15 minutes, ultrasonication was performed at an ultrasonic frequency of 1.25 kHz for 9 minutes to uniformly disperse the nano-silica particles, and after the acetone volatilized, nano-silica particles with low surface energy were prepared. Wherein, the acetone containing polydimethylsiloxane is prepared by mixing dimethylsiloxane and acetone and mechanically stirring at 200 r / min for 15 minutes.

[0035] (2) The mass ratio of the low surface energy nano-silica particles, acrylic resin and ethylene glycol prepared in step (1) is 2:3:1, and after the three are mixed, they are mixed at 92°C at 200r / min mechanically stirred for 60min to prepare an antifouling flashover superhydrophobic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com