Carbon nitride/cobalt sulfide super capacitor electrode material, preparation method thereof, and application thereof

A technology for supercapacitors and electrode materials, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

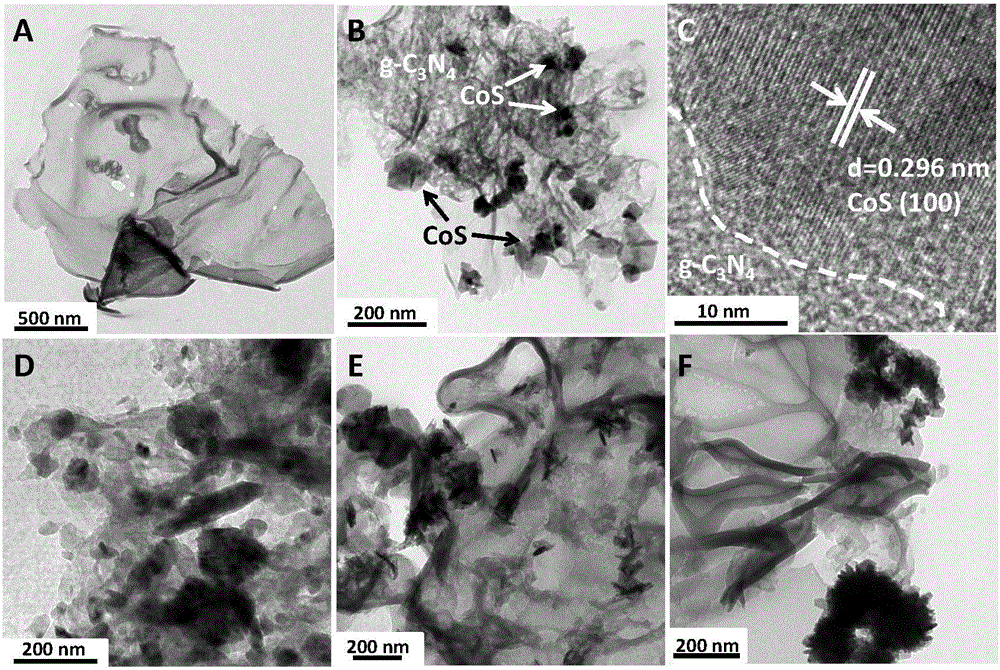

[0029] Example 1: g-C 3 N 4 Preparation of nanosheets:

[0030] Weigh 10 g of urea into a semi-closed crucible, dry it first, then transfer it to a temperature-programmed tube furnace for calcination, set the heating rate at 2.3°C / min, and calcine at 550°C for 5h. After cooling down to room temperature naturally, take it out, grind it into powder with a mortar, and use 0.1mol / L dilute HNO 3 Wash several times to remove residual alkaline species, then wash the product with distilled water and absolute ethanol, centrifuge, and dry to obtain g-C 3 N 4 Nanosheets.

Embodiment 2

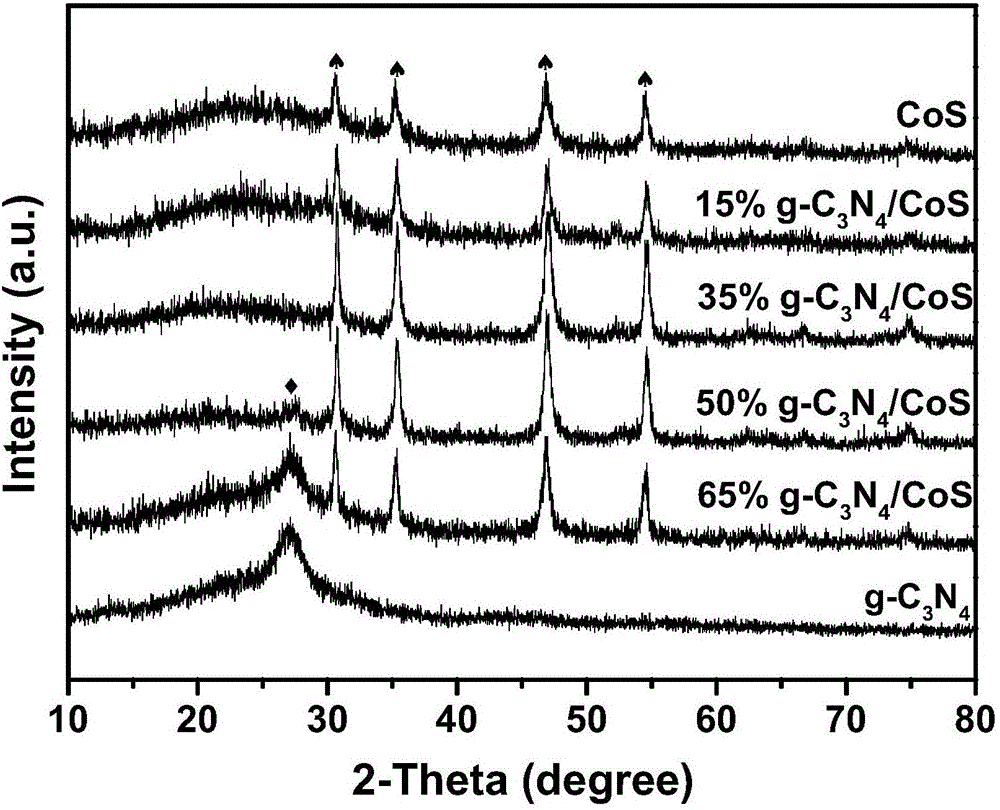

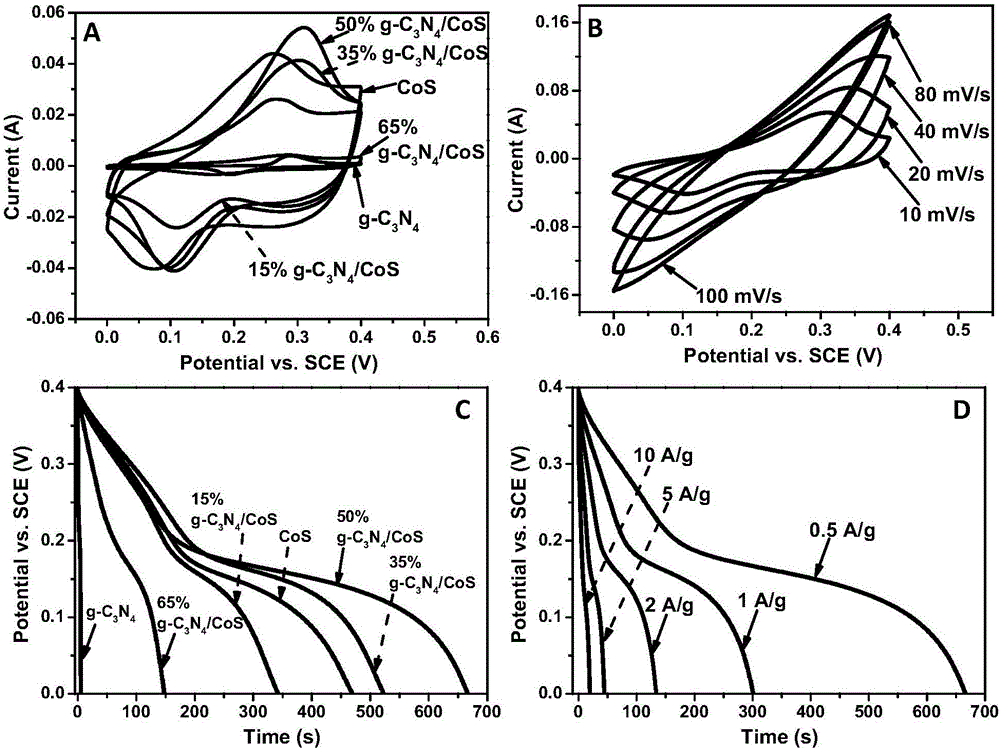

[0031] Example 2: 15% g-C 3 N 4 Preparation of / CoS composite nanomaterials:

[0032] 15% g-C 3 N 4 / CoS composite nanomaterials were synthesized using a one-step hydrothermal method: weigh 0.8mmol of CoCl 2 ·H 2 0 and 1.6mmol of thiourea in a 100mL beaker, add 36mL of absolute ethanol, magnetically stirred for 30min to completely dissolve it, then add 0.0128g of g-C obtained in Example 1 3 N 4 , ultrasonic for 30min, wait for g-C 3 N 4 After dispersing evenly, add 4mL of ethylenediamine and stir for another 10min, then add the resulting solution into a 50mL polytetrafluoroethylene-lined reaction kettle, put it in an oven, and react with solvent heat at 180°C for 12h, and wait to cool to room temperature after the reaction Afterwards, the precipitate was centrifuged, washed with water and alcohol three times each, dried in an oven and ground to obtain 15% g-C 3 N 4 / CoS composite nanomaterials.

Embodiment 3

[0033] Example 3: 35% g-C 3 N 4 Preparation of / CoS composite nanomaterials:

[0034] 35% g-C 3 N 4 / CoS composite nanomaterials were synthesized using a one-step hydrothermal method: weigh 0.8mmol of CoCl 2 ·H 2 O and 1.6mmol of thiourea were placed in a 100mL beaker, 36mL of absolute ethanol was added, and after magnetic stirring for 30min to completely dissolve it, 0.0392g of the g-C obtained in Example 1 was added. 3 N 4 , ultrasonic for 30min, wait for g-C 3 N 4 After dispersing evenly, add 4mL of ethylenediamine and stir for another 10min, then add the resulting solution into a 50mL polytetrafluoroethylene-lined reaction kettle, put it in an oven, and react with solvent heat at 180°C for 12h, and wait to cool to room temperature after the reaction Afterwards, the precipitate was centrifuged and washed three times with water and alcohol, and then dried in an oven and ground to obtain 35% g-C 3 N 4 / CoS composite nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com