LED epitaxial structure and growing method thereof

An epitaxial structure and growth method technology, applied in the field of electronics, can solve the problems of high Al content in the electron blocking layer, discontinuous energy band bending, and unfavorable hole injection, so as to achieve increased hole injection efficiency, improved crystal quality, and convenient parameters. The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

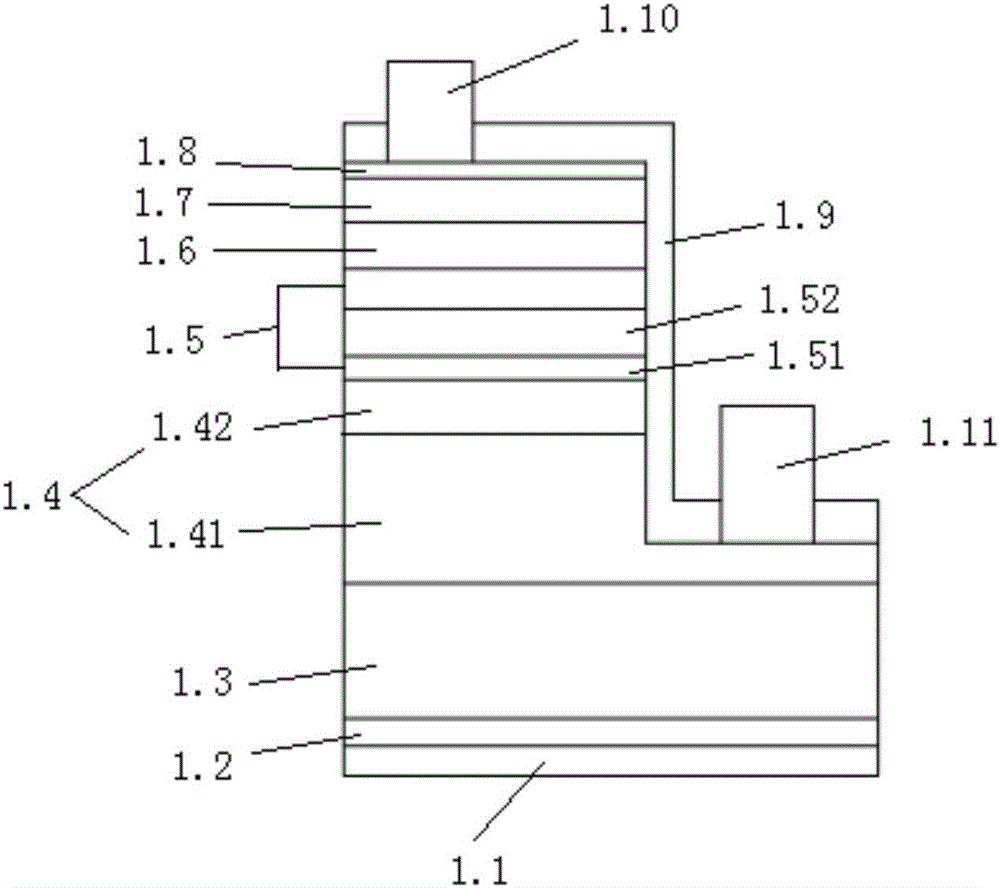

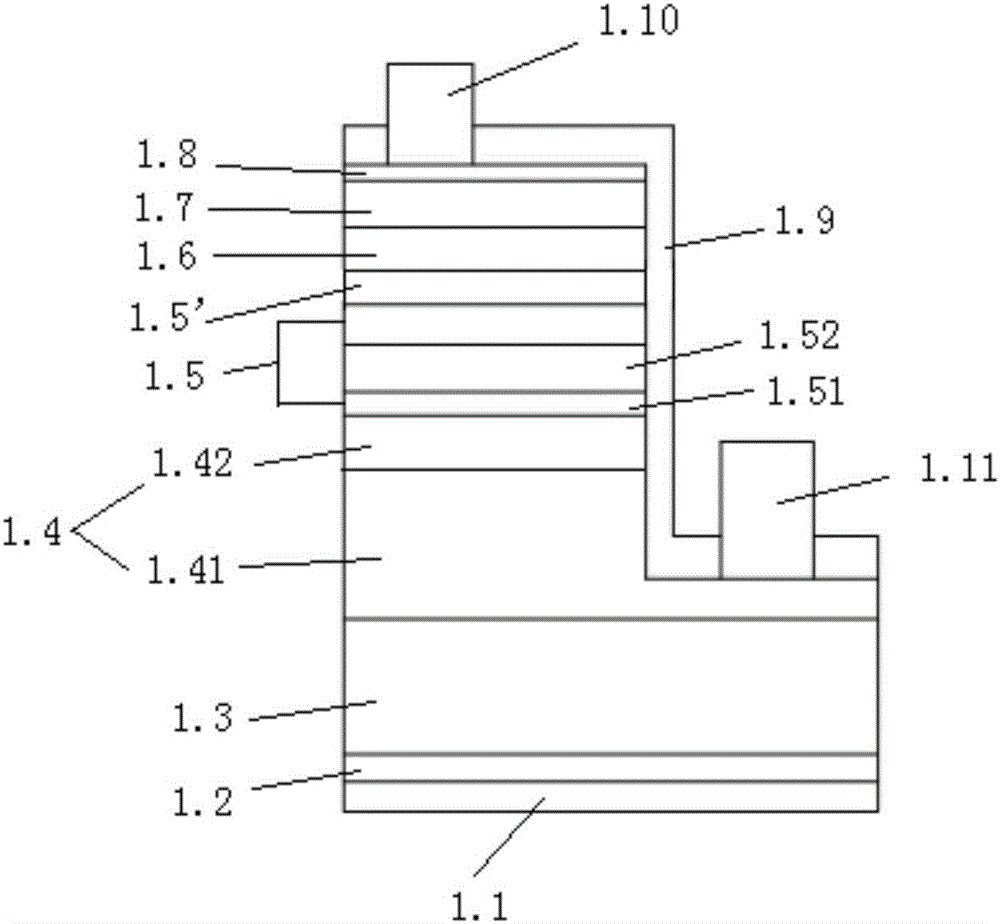

[0050] see figure 2 , an LED epitaxial structure, sequentially stacked sapphire substrate 1.1, low-temperature buffer layer 1.2, undoped GaN layer 1.3, Si-doped n-type GaN layer 1.4, In x Ga (1-x) N / GaN light-emitting layer 1.5, p-type InN layer 1.5', p-type AlGaN layer 1.6 and magnesium-doped p-type GaN layer 1.7.

[0051] The thickness of the low-temperature buffer layer 1.2 is 20-40 nm, and the low-temperature buffer layer 1.2 is corroded into a plurality of irregular small islands.

[0052] The thickness of the undoped GaN layer 1.3 is 2-4 μm.

[0053] The Si-doped n-type GaN layer 1.4 includes a first Si-doped n-type GaN layer 1.41 and a second Si-doped n-type GaN layer 1.42 stacked in sequence, and the first Si-doped n-type GaN layer The thickness of the layer 1.41 is 3-4 μm, and the thickness of the second Si-doped n-type GaN layer 1.42 is 200-400 nm.

[0054] The In x Ga (1-x) The N / GaN light-emitting layer 1.5 includes 7-15 monomers stacked, and the monomers in...

Embodiment 2- Embodiment 3

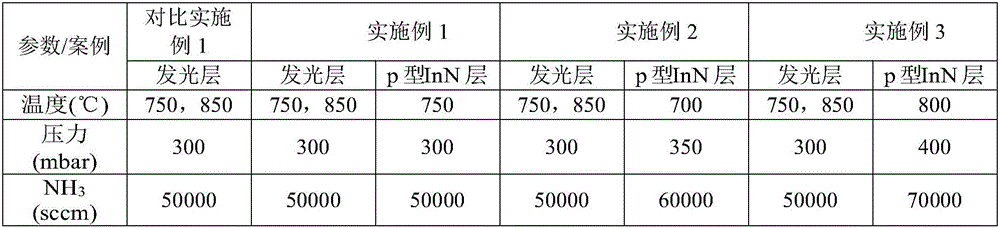

[0072] The difference between embodiment 2-3 and embodiment 1 is the parameters in table 1:

[0073] The part parameter statistical table of table 1 comparative embodiment, embodiment 1-embodiment 3

[0074]

[0075]

[0076] The LED epitaxial structures obtained in Examples 2-3 are marked as S2-S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com