Graphene oxide/phosphamide composite material and preparation method thereof

A composite material and phosphoramide technology, applied in the field of uranyl ion adsorption materials and materials, can solve the problems of difficult separation and insufficient adsorption capacity, and achieve the effects of low production cost, simple operation and excellent uranyl ion adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

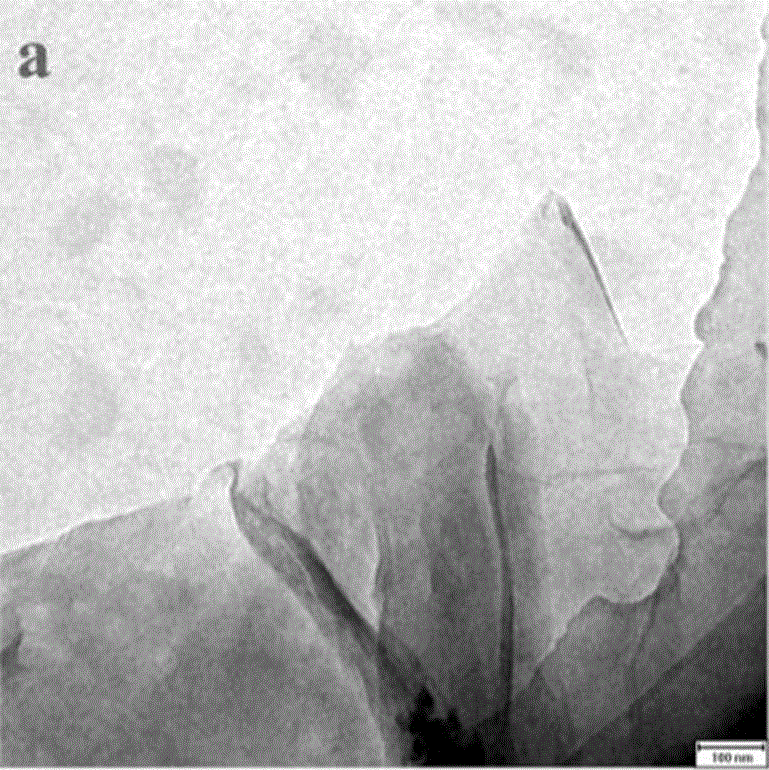

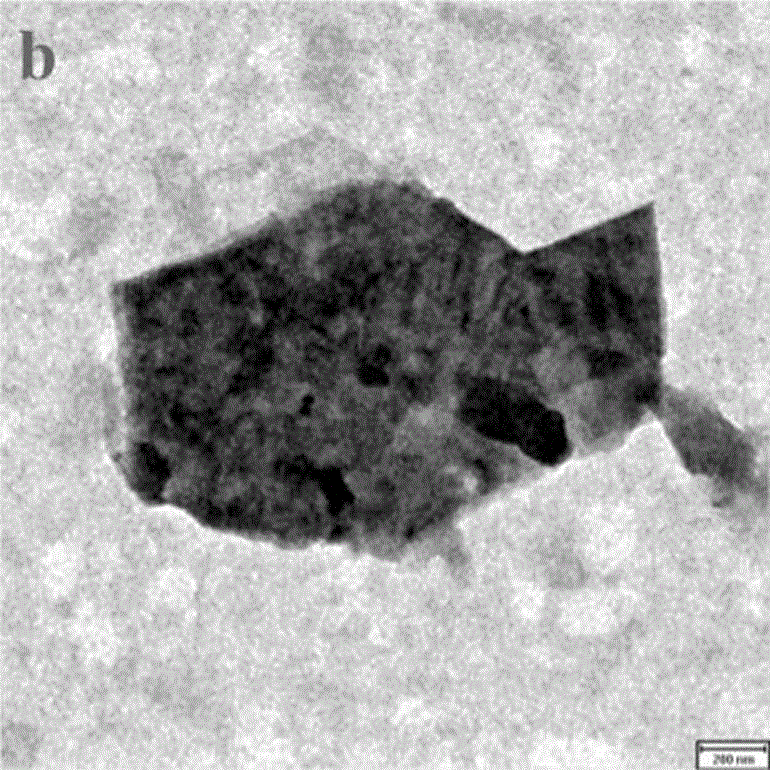

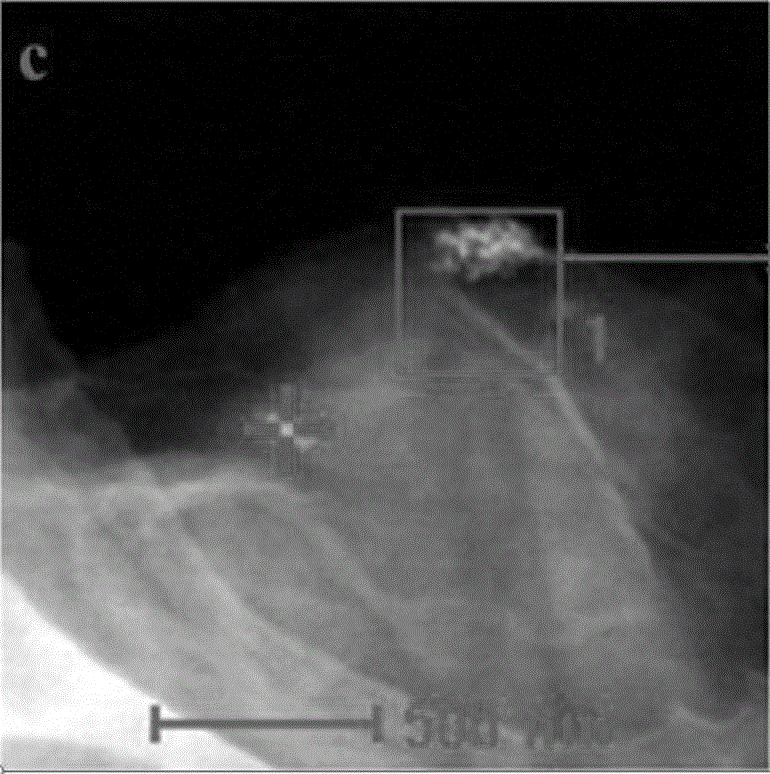

Image

Examples

Embodiment 1

[0047] 1. Sample preparation

[0048] (1) Synthesis of graphene oxide

[0049] Add 1g of graphite powder into a 250mL round-bottomed flask containing 23mL of concentrated sulfuric acid, stir for 30min, put it in an ice-water bath, and add 3g of KMnO 4 Slowly added to the solution, and continued to stir at 35 °C for 2 h to obtain the first solution. Subsequently, 50mL of ultrapure water was added to the first solution, and the temperature was raised to 90°C, and then 140mL of ultrapure water and 2.5mL of H 2 o 2 (that is, adding a low-concentration hydrogen peroxide solution) to obtain a reaction solution. The reaction solution was filtered to obtain a black solid, which was washed with dilute hydrochloric acid and ultrapure water respectively to obtain a brownish-yellow primary filter. Put the primary filter in a dialysis bag, and dialyze it with ultrapure water several times to remove soluble impurities; finally, centrifuge at 10,000 rpm for 2 hours, and dry it in vacuum ...

Embodiment 2

[0070] (1) Synthesis of graphene oxide

[0071] Add 1g of graphite powder into a 250mL round-bottomed flask containing 24mL of concentrated sulfuric acid, stir for 28min, put it in an ice-water bath, and add 3g of KMnO 4 Slowly added to the solution, and continued to stir at 35 °C for 1.8 h to obtain the first solution. Subsequently, 55mL of ultrapure water was added to the first solution, and the temperature was raised to 90°C, and then 145mL of ultrapure water and 2.5mL of H 2 o 2 (that is, adding a low-concentration hydrogen peroxide solution) to obtain a reaction solution. The reaction solution was filtered to obtain a black solid, which was washed with dilute hydrochloric acid and ultrapure water respectively to obtain a brownish-yellow primary filter. Put the primary filter in a dialysis bag, and dialyze it with ultrapure water several times to remove soluble impurities; finally, centrifuge at 10,000 rpm for 2 hours, and dry it in vacuum at 60°C for 2 hours to obtain ...

Embodiment 3

[0078] (1) Synthesis of graphene oxide

[0079] Add 1g of graphite powder into a 250mL round bottom flask containing 23mL of concentrated sulfuric acid, stir for 45min, place in an ice-water bath, and then add 3.2g of KMnO 4 Slowly added to the solution, and continued to stir at 36 °C for 2 h to obtain the first solution. Subsequently, 60mL of ultrapure water was added to the first solution, and the temperature was raised to 88°C, and then 140mL of ultrapure water and 2.5mL of H 2 o 2 (that is, adding a low-concentration hydrogen peroxide solution) to obtain a reaction solution. The reaction solution was filtered to obtain a black solid, which was washed with dilute hydrochloric acid and ultrapure water respectively to obtain a brownish-yellow primary filter. Put the primary filter in a dialysis bag, and dialyze it with ultrapure water several times to remove soluble impurities; finally, centrifuge at 10,000 rpm for 2.2 hours, and dry it in vacuum at 60°C for 2 hours to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com