Preparation method of tin dioxide/copper oxide composite nano material with spherical hierarchical structure

A composite nanomaterial and hierarchical structure technology is applied in the field of preparation of hierarchically structured tin dioxide/copper oxide composite nanomaterials, which can solve the problems of small specific surface area, influence on the performance of catalysts, and high calcination temperature, and achieve the effect of high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

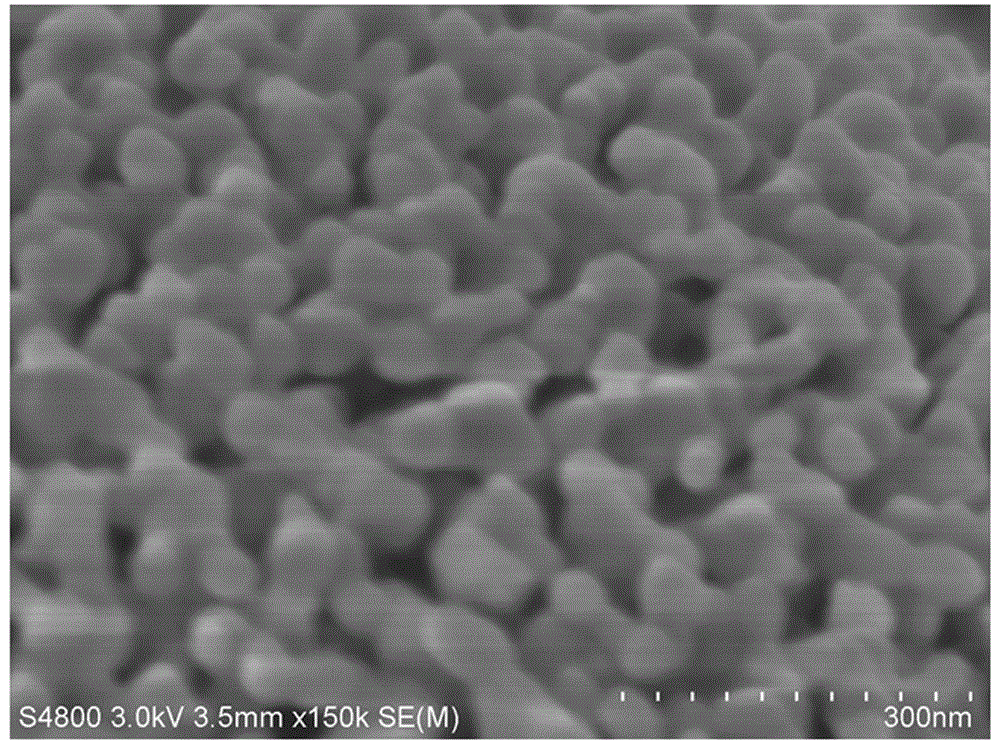

[0035] Accurately weigh copper acetylacetonate and tin tetrachloride in a molar ratio of 1:1 and put them into methanol (12C, 99.95%) to stir and dissolve. The molar concentration of copper acetylacetonate is 0.01 mol / L. The resulting mixed solution was subjected to solvothermal reaction, the solvothermal reaction temperature was 200 ° C, and the solvothermal reaction time was 24 hours. After the solvothermal reaction was completed, it was naturally cooled to room temperature, and the product obtained by the reaction was filtered and washed and placed in an oven at a programmed temperature increase rate of 5°C / min, and dried at 120°C for 5 hours. Then place it in a muffle furnace for calcination, the calcination time is 8 hours, the calcination temperature is 500 °C, and the heating rate is 10 °C / min. After natural cooling, the spherical hierarchical structure tin dioxide / copper oxide composite nanomaterial is obtained. The size of the large spheres is 3 mm, the size of the n...

Embodiment 2

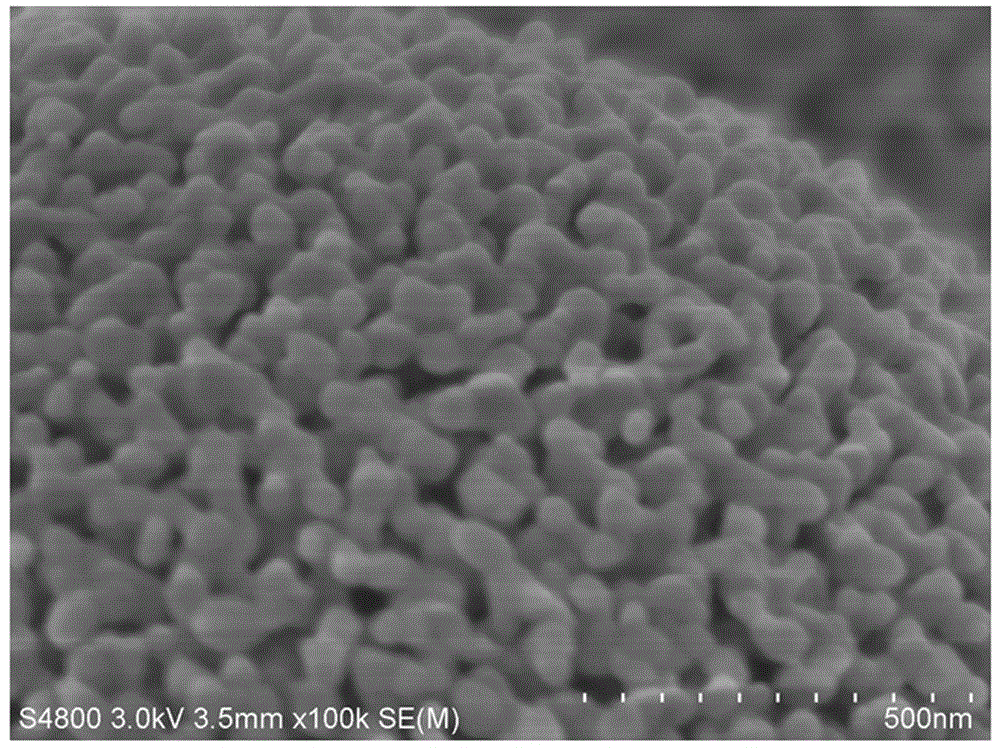

[0038]Accurately weigh copper acetylacetonate and tin tetrachloride at a molar ratio of 1:1 and put them into methanol (12C, 99.95%) to stir and dissolve. The molar concentration of copper acetylacetonate is 0.02 mol / L. The mixed solution obtained is carried out solvothermal reaction, and the solvothermal reaction temperature is 110 ℃, and the solvothermal reaction time is 48 hours. After the solvothermal reaction was completed, it was naturally cooled to room temperature, and the product obtained by the reaction was filtered and washed and placed in an oven at a programmed temperature increase rate of 5°C / min, and dried at 120°C for 5 hours. Then place it in a muffle furnace for calcination, the calcination time is 4 hours, the calcination temperature is 700 °C, and the heating rate is 10 °C / min. After natural cooling, the spherical hierarchical structure tin dioxide / copper oxide composite nanomaterial is obtained. The size of the large spheres is 6 mm, the size of the nanop...

Embodiment 3

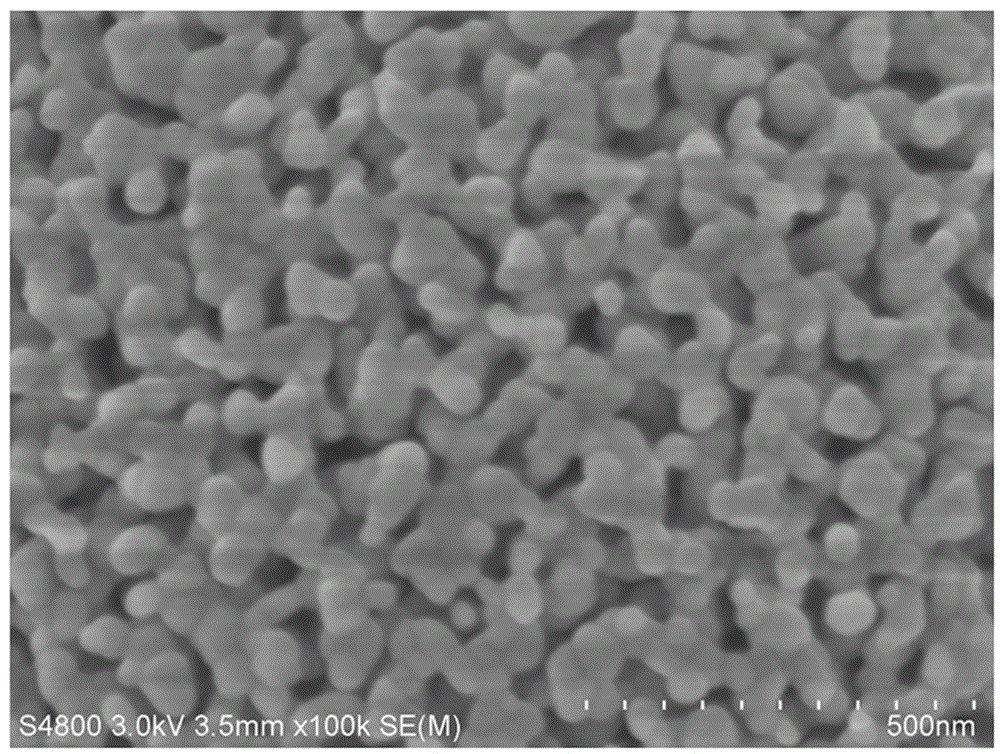

[0041] Accurately weigh copper acetylacetonate and tin tetrachloride at a molar ratio of 1:1 and put them into methanol (12C, 99.95%) to stir and dissolve. The molar concentration of copper acetylacetonate is 0.03 mol / L. The resulting mixed solution was subjected to solvothermal reaction, the solvothermal reaction temperature was 220 ° C, and the solvothermal reaction time was 12 hours. After the solvothermal reaction was completed, it was naturally cooled to room temperature, and the product obtained by the reaction was filtered and washed and placed in an oven at a programmed temperature increase rate of 10 °C / min, and dried at 100 °C for 5 hours. Then place it in a muffle furnace for calcination, the calcination time is 5 hours, the calcination temperature is 800 °C, and the heating rate is 10 °C / min. After natural cooling, the spherical hierarchical structure tin dioxide / copper oxide composite nanomaterial is obtained. The size of the large spheres is 4 mm, the size of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com