Preparation method of improving prestress of cement electric pole

A technology for cement poles and poles, which is applied in the field of concrete processing and cement products. It can solve the problems of poor acid, alkali and salt corrosion resistance of poles, high cost of steel bar production equipment, and difficult steel bar production, so as to shorten the production cycle and speed up production. The effect of shortening the setting time and curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

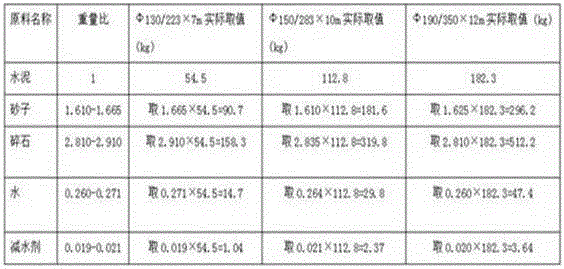

[0031] Example 1: The specification model is Φ130 / 223×7m Production and processing methods:

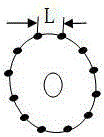

[0032] (A) The selected raw materials are: cement, sand, gravel, water, water reducing agent and steel bars, and then weigh the mass of each pole with a specification model of Φ130 / 223×7m, cement 54.5kg, sand 90.7kg, gravel 158.3kg, 14.7kg of water and 1.04kg of water reducing agent, among which there are 9 main steel bars for each pole, the length is 7000m±1.5mm, the diameter of the main steel bars is 5-8mm, and several winding bars and erecting rings The diameter of the erecting ring steel bar is 5-8mm, the diameter deviation of the erecting ring is ≤1.5mm, the unevenness is ≤2.5mm, the out-of-roundness is ≤1.5mm, the diameter of the winding bar is 2.5-5mm, and the cement specification is P•Ⅱ52R.5R, the fineness modulus of the sand is 2~2.5, the crushed stone adopts continuous particle size of 5~20mm, and the crushing index is ≤8%;

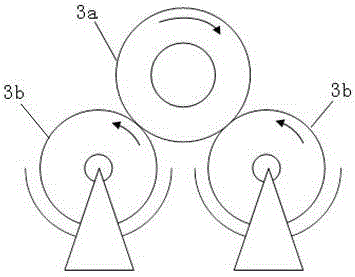

[0033] (B) Processing of the steel skeleton cage...

Embodiment 2

[0041] Example 2: The specification model is Φ150 / 283×10m Production and processing methods:

[0042] (A) The selected raw materials are: cement, sand, gravel, water, water reducing agent and steel bars, and then weigh the mass of each pole with a specification model of Φ150 / 283×10, cement 112.8kg, sand 181.6kg, gravel 319.83kg, 29.8kg of water and 2.37kg of water reducing agent, including 15 main steel bars for each pole, the length is 10000m±1.5mm, the diameter of the main steel bars is 5-8mm, several winding bars and erecting rings, The diameter of the steel bars for erecting rings is 5-8mm, the diameter deviation of the erecting rings is ≤1.5mm, the unevenness is ≤2.5mm, the out-of-roundness is ≤1.5mm, the diameter of the winding bars is 2.5-5mm, and the cement specification is P• Ⅱ52R.5R, the fineness modulus of the sand is 2~2.5, the crushed stone adopts continuous particle size of 5~20mm, and the crushing index is ≤8%;

[0043] (B) Processing of the steel skeleton cage...

Embodiment 3

[0051] Embodiment 3: The specification model is Φ190 / 350×12m Production and processing method:

[0052] (A) The selected raw materials are: cement, sand, gravel, water, water reducing agent and steel bars, and then weigh the mass of each pole with a specification model of Φ190 / 350×12m, cement 182.3kg, sand 296.2kg, gravel 512.2kg, 47.4kg of water and 3.64kg of water reducing agent, including 12 main steel bars for each pole, the length is 12000m±2mm, the diameter of the main steel bars is 5-8mm, several winding bars and vertical rings, The diameter of the vertical ring steel bar is Φ5-8mm, the diameter deviation of the vertical ring is ≤1.5mm, the unevenness is ≤2.5mm, the out-of-roundness is ≤1.5mm, the winding diameter is 2.5-5mm, and the cement specification is P•Ⅱ52R. 5R, the fineness modulus of the sand is 2-2.5, the crushed stone adopts a continuous particle size of 5-20mm, and the crushing index is ≤8%;

[0053] (B) Processing of the steel skeleton cage: the selected e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com