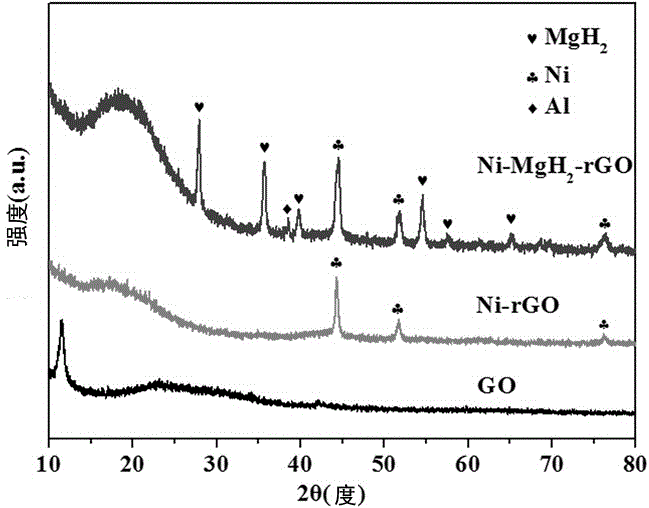

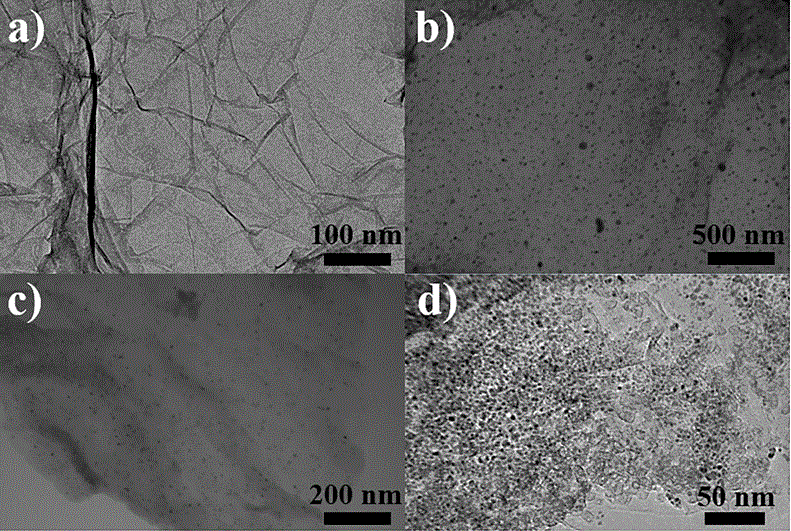

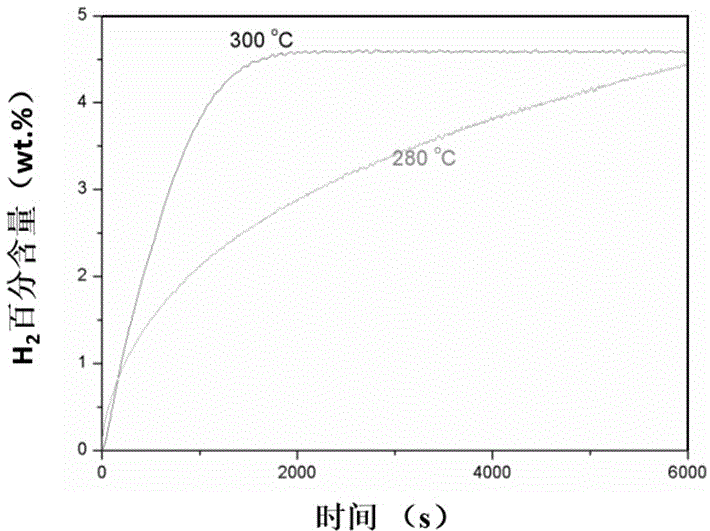

Hydrogen storage composite material MgH2-Ni-rGO and method for preparing same

A composite material, mgh2-ni-rgo technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of high dehydrogenation temperature and slow dehydrogenation kinetics, and achieve low equipment requirements and moderate cost , easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of graphene oxide GO

[0029] Weigh 2 g of natural graphite and pour it into a three-necked flask, add 100 mL of 65% HNO 3 , then slowly add 100 mL of 98% H at 0°C in an ice-water bath 2 SO 4 , after stirring for 1 h, add 10 g KMnO 4 , heated to 35 °C for 2 h, and then heated to 75 °C for 1 h; after cooling to room temperature, 500 mL of distilled water was added to dilute the concentrated acid to obtain a brown colloidal substance, and then 40 mL of 35% H 2 o 2 and 100 mL of 10% HCl to obtain a brownish-yellow solution; centrifuge and wash until neutral; dry in air at 50-60 °C to obtain graphene oxide;

[0030] (2) Ni(OH) 2 -GO preparation

[0031] 0.09 g C 4 h 5 o 6 Ni·4H 20, 0.07 g of cetyltrimethylammonium bromide and 0.1 g of hexamethylenetetramine were dissolved in 40 mL of deionized water, and another 160 mg of GO was weighed in 40 mL of deionized water for 2 h, and then the two After mixing and stirring for 10 minutes, place them in a ...

Embodiment 2

[0037] (1) Preparation of graphene oxide GO

[0038] Weigh 2.5 g of natural graphite and pour it into a three-neck flask, add 150 mL of 65% HNO 3 , then slowly add 150 mL of 98% H in an ice-water bath at 0°C 2 SO 4 , after stirring for 1 h, add 15 g KMnO 4 , heated to 35 °C for 2 h, then raised to 75 °C for 1 h; cooled to room temperature, added 500 mL of distilled water to dilute the concentrated acid to obtain a brown colloidal substance, then added 50 mL of 35% H 2 o 2 and 150 mL of 10% HCl to obtain a brownish-yellow solution; centrifuge and wash until neutral; dry in air at 50-60 °C to obtain graphene oxide;

[0039] (2) Ni(OH) 2 -GO preparation

[0040] 0.1 g C 4 h 5 o 6 Ni·4H 2 0. Dissolve 0.08 g of cetyltrimethylammonium bromide and 0.14 g of hexamethylenetetramine in 40 mL of deionized water, and weigh 180 mg of GO in 40 mL of deionized water for 2 h. After mixing and stirring for 10 min, put it in a polytetrafluoroethylene reactor, react at 120 ° C for 4 h...

Embodiment 3

[0046] First three steps are identical with the first three steps of embodiment 1;

[0047] MgH 2 - Preparation of Ni-rGO

[0048] Take 30 mg Ni-rGO, 45 mL cyclohexane, and 1.8 mL dibutylmagnesium in an autoclave, add 4 MPa H 2 , sonicated for 40 min, stirred for 2 h, reacted in an oil bath at 200 °C for 24 h, after the reaction, vacuumed at 80 °C for 12 h to remove the solvent to obtain MgH 2 -Ni-rGO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com