Water softening apparatus and water softening method

A technology for softening water and softening water tanks, which is applied in descaling and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc., and can solve the high operating cost, complicated operation management, and ion exchange softening method. Pretreatment requirements Strict and other problems, to achieve the effect of low operating cost and simple softening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

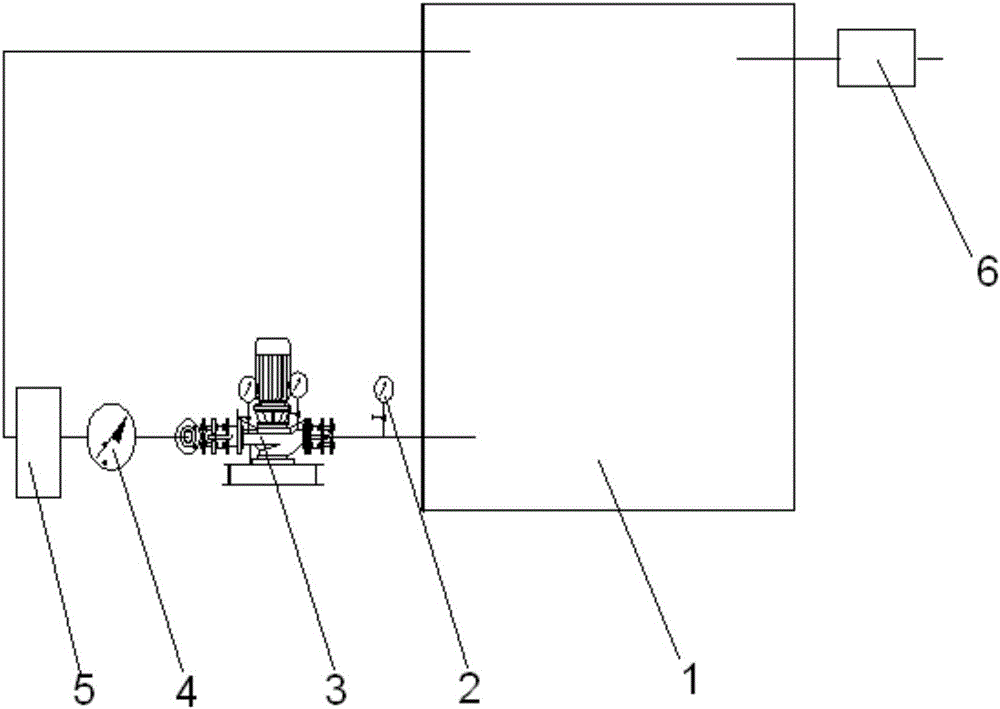

[0028] Refer to attached figure 1 As shown, the water softening device of the present invention includes a softened water tank 1, a water pump 3 and a degasser 4. The softened water tank 1 is a fully enclosed water tank. on the pipe.

[0029] In this embodiment, the softened water tank 1 adopts concrete pools, glass fiber reinforced plastic water tanks, carbon steel anti-corrosion water tanks or stainless steel water tanks, PE water tanks, etc. for anti-seepage treatment, and is used for storing hard water to be softened and softened water after softening.

[0030] The water pump 3 adopts an existing pump body such as a centrifugal pump, a plunger pump or a self-priming pump, and is used to pump the hard water to be softened in the softened water tank 1 into the degasser 4, and re-enter the liquid after passing through the degasser 4. In the softening water tank 1, enter the cycle softening process again.

[0031] The degasser 4 adopts a vacuum degasser or a membrane degasse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com