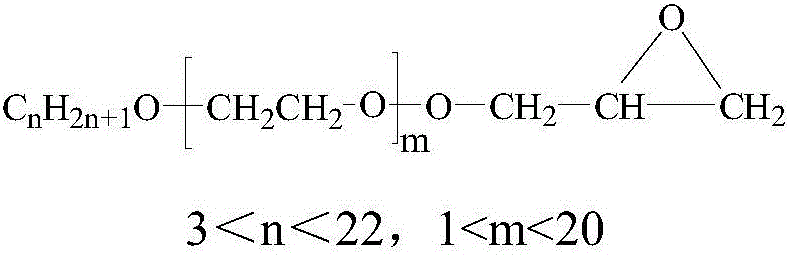

Fatty alcohol-polyoxyethylene ether glycidyl ether and preparation method thereof

A technology of alcohol polyoxyethylene ether and glycidyl ether, which is applied in the field of fatty alcohol polyoxyethylene ether glycidyl ether and its preparation, can solve the problem of high product viscosity, achieve simple synthesis process, high controllability, and ensure product phase The effect of the indicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

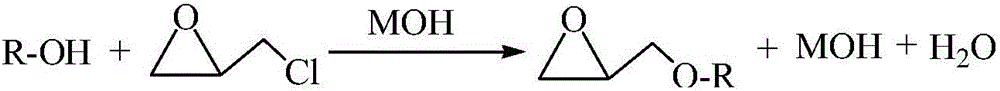

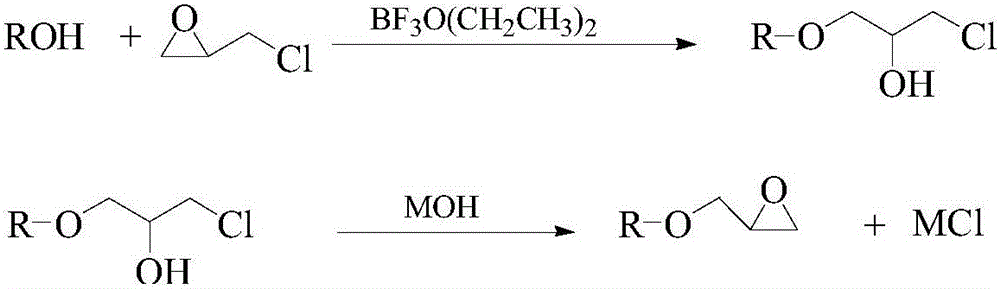

Method used

Image

Examples

Embodiment 1-1

[0067] 1.0gAlCl 3 , 100g magnesium silicate powder, add 5.6g concentrated hydrochloric acid and appropriate amount of water, knead and mix to form a semi-wet shape, which can be smoothly extruded into strips, which is the most suitable. Heating and dipping in an oil bath at 80-90°C for 24 hours, and then A single-screw extruder is used to extrude into a strip, then dried at 110° C., calcined at 450° C. in an air atmosphere for 2 hours, and sieved to obtain a treated magnesium silicate adsorbent of 100-200 mesh.

Embodiment 1-2

[0069] 3.0gAlCl 3 100g magnesium silicate powder, add 16g concentrated hydrochloric acid and appropriate amount of water, knead and knead to form a semi-wet shape, which can be smoothly extruded into strips. A screw extruder extrudes into strips, then dried at 110°C, calcined at 450°C in an air atmosphere for 2 hours, and sieved to obtain 100-200 mesh treated magnesium silicate adsorbent.

Embodiment 1-3

[0071] 5.0gAlCl 3 100g of magnesium silicate powder, add 27.8g of concentrated hydrochloric acid and appropriate amount of water, knead and knead, mix and bond into a semi-wet shape, which can be smoothly extruded into strips, which is the most suitable. Heating and dipping in an oil bath at 80-90°C for 24h, and then A single-screw extruder is used to extrude into a strip, then dried at 110° C., calcined at 450° C. in an air atmosphere for 2 hours, and sieved to obtain a treated magnesium silicate adsorbent of 100-200 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com