Fluorescent multicolor floor and preparation method thereof

A colorful and floor technology, applied in the field of coatings, can solve the problems of poor resistance to mortar stress cracks, short open storage time of coatings, poor light aging resistance, etc., and achieve excellent light aging resistance, high hardness and high adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] A method for preparing a fluorescent colorful floor, comprising the following steps in sequence:

[0036] S1: Prepare base coat:

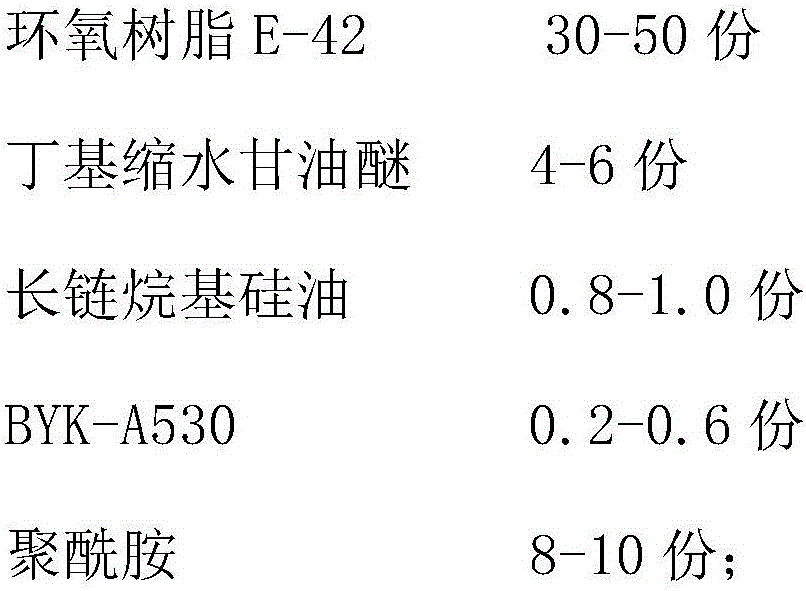

[0037] Add 30-50 parts of epoxy resin E-42, 4-6 parts of butyl glycidyl ether, 0.8-1.0 parts of long-chain alkyl silicone oil and 0.2-0.6 parts of BYK-A530 into the first dispersion container; at 1000-1200r Disperse for 20-30 minutes at a speed of 1 / min; when in use, add 8-10 parts of polyamide, stir while adding, and then continue stirring for 3-5 minutes, and evenly bond and cover the well-mixed primer layer on the ground base layer on the upper surface of

[0038] S2: Prepare component A, including the following sub-steps performed in sequence:

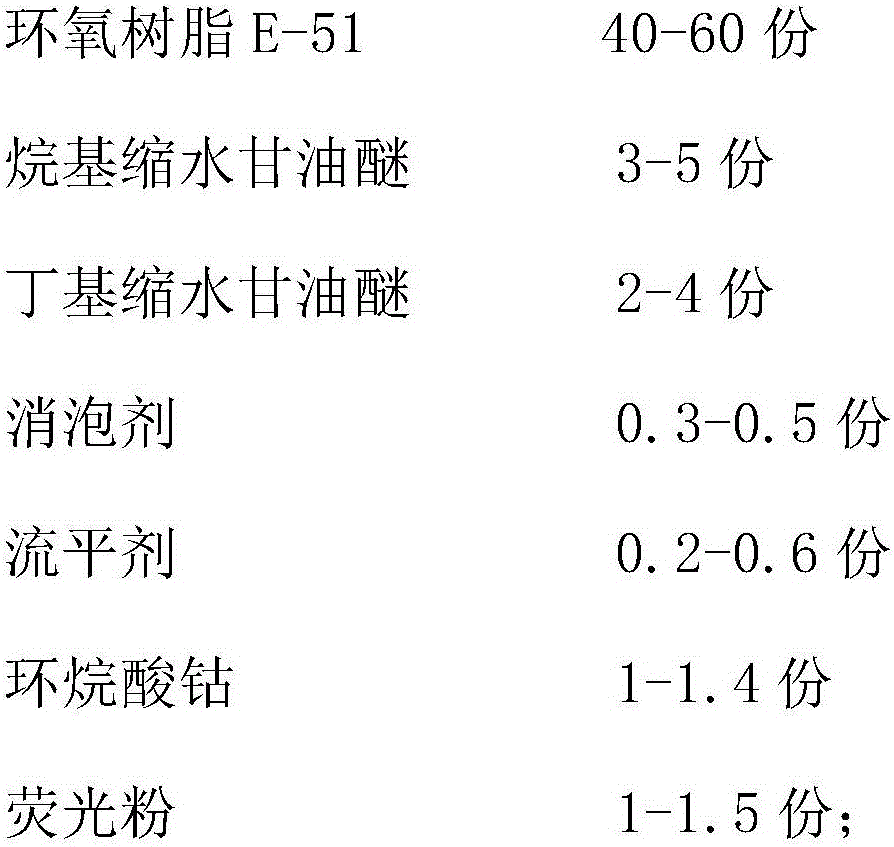

[0039] 1) Add 40-60 parts of epoxy resin E-51, 3-5 parts of alkyl glycidyl ether, and 2-4 parts of butyl glycidyl ether into the second dispersion container, and disperse at the speed of 1000-1200r / min 20-30 minutes;

[0040] 2) Adjust the speed of the disperser to 1200-1800r / min, add 0.3-0.5...

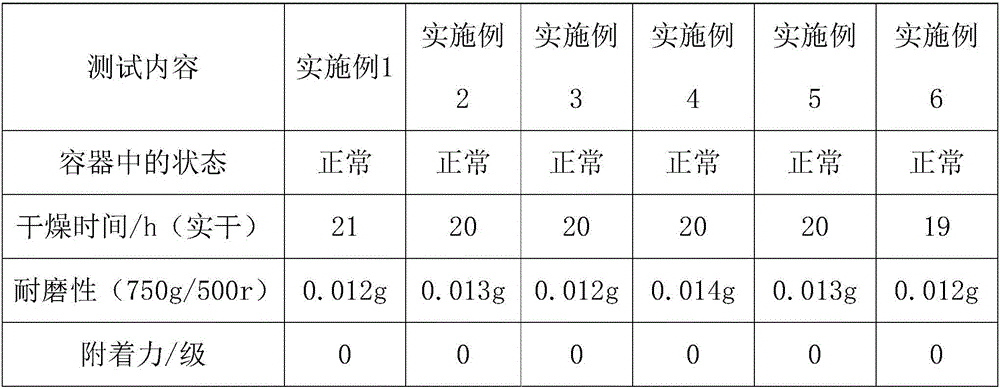

Embodiment 1

[0047] A method for preparing a fluorescent colorful floor, comprising the following steps in sequence:

[0048] S1: Prepare base coat:

[0049] Add 40 parts of epoxy resin E-42, 5 parts of butyl glycidyl ether, 0.9 parts of long-chain alkyl silicone oil and 0.4 parts of BYK-A530 into the first dispersion container; disperse at 1100r / min for 25 minutes; use At the same time, add 9 parts of polyamide, stir while adding, and then continue to stir for 4 minutes, and evenly bond and cover the evenly mixed primer layer on the upper surface of the ground base layer;

[0050] S2: Prepare component A, including the following sub-steps performed in sequence:

[0051] 1) Add 50 parts of epoxy resin E-51, 4 parts of alkyl glycidyl ether, and 3 parts of butyl glycidyl ether into the second dispersion container, and disperse for 25 minutes at a speed of 1100r / min;

[0052] 2) Adjust the speed of the disperser to 1500r / min, add 0.4 part of defoamer and 0.4 part of leveling agent while dis...

Embodiment 2

[0057] A method for preparing a fluorescent colorful floor, comprising the following steps in sequence:

[0058] S1: Prepare base coat:

[0059] Add 36 parts of epoxy resin E-42, 4.6 parts of butyl glycidyl ether, 0.85 parts of long-chain alkyl silicone oil and 0.26 parts of BYK-A530 into the first dispersion container; disperse at 1180r / min for 24 minutes; use At the same time, add 8.5 parts of polyamide, stir while adding, and then continue to stir for 4.5 minutes, and evenly bond and cover the evenly mixed primer layer on the upper surface of the ground base layer;

[0060] S2: Prepare component A, including the following sub-steps performed in sequence:

[0061] 1) Add 48 parts of epoxy resin E-51, 3.5 parts of alkyl glycidyl ether, and 2.4 parts of butyl glycidyl ether into the second dispersion container, and disperse for 24 minutes at a speed of 1180r / min;

[0062] 2) Adjust the speed of the disperser to 1500r / min, add 0.35 part of defoamer and 0.5 part of leveling ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com