Epoxy coal asphalt anti-corrosion paint and manufacturing method

A technology of anti-corrosion coatings and epoxy coal tar pitch, which is applied in the direction of anti-corrosion coatings, asphalt coatings, epoxy resin coatings, etc., and can solve the problems of poor resistance to mortar stress cracks, short storage time of coatings in the open air, and poor light aging resistance of coatings, etc. problems, to achieve excellent physical and mechanical properties, good anti-microbial damage, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

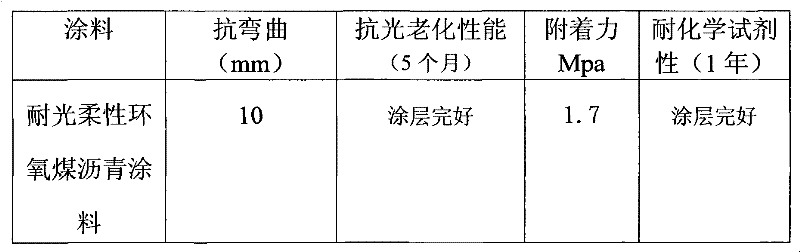

Embodiment 1

[0022] The light-resistant flexible epoxy coal tar pitch anticorrosion paint used for the outer wall of PCCP (prestressed steel tube concrete pipe) and its manufacturing method.

[0023] Add successively the E-20 bisphenol A type epoxy resin of 1 weight part, the xylene of 0.23 weight part, the butanol of 0.11 weight part, the methyl ethyl ketone of 0.05 weight part, the coal tar pitch resin of 0.7 weight part in the stainless steel bucket Liquid, 0.25 parts by weight of chlorinated ethylene vinyl acetate copolymer, 0.05 parts by weight of precipitated barium sulfate, 0.01 parts by weight of sericite powder, 0.008 parts by weight of talcum powder, 0.01 parts by weight of 132. Disperse at high speed for 0.5-1 hour, then grind for 1 hour with a sand mill. To the ground product, add 0.008 parts by weight of coupling agent 201, 0.01 parts by weight of 3650 additives and 0.008 parts by weight of silicone defoamer, and then dispersed at high speed for 30 minutes to prepare compon...

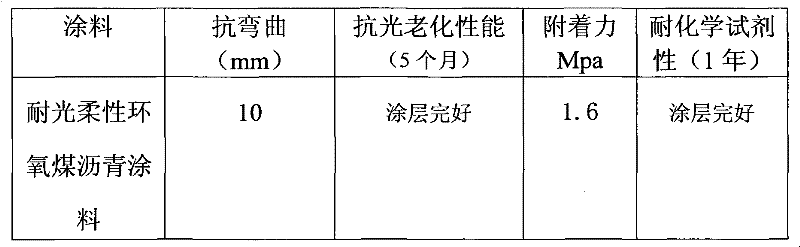

Embodiment 2

[0029] The light-resistant flexible epoxy coal tar pitch anticorrosion paint used for the outer wall of PCCP (prestressed steel tube concrete pipe) and its manufacturing method.

[0030] Add successively the E-20 bisphenol A type epoxy resin of 1 weight part, the xylene of 0.25 weight part, the butanol of 0.13 weight part, the methyl ethyl ketone of 0.06 weight part, the coal tar pitch resin of 0.75 weight part in stainless steel bucket liquid, 0.27 parts by weight of chlorinated ethylene vinyl acetate copolymer, 0.05 parts by weight of precipitated barium sulfate, 0.01 parts by weight of sericite powder, 0.008 parts by weight of talcum powder, 0.009 parts by weight of 132, disperse at high speed for 0.5 hours, and then grind for 1 hour with a sand mill. To the ground product, add 0.008 parts by weight of coupling agent 201, 0.011 parts by weight of 3650 additives and 0.008 parts by weight of silicone defoamer, and then dispersed at high speed for 30 minutes to prepare comp...

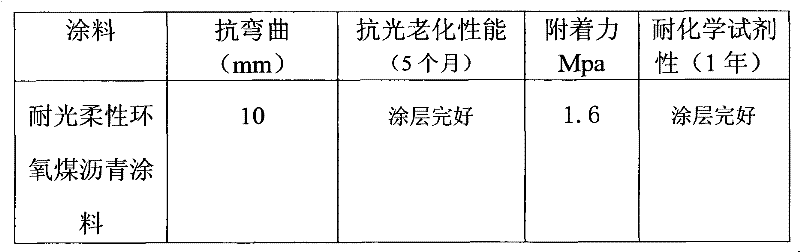

Embodiment 3

[0036] The light-resistant flexible epoxy coal tar pitch anticorrosion paint used for the outer wall of PCCP (prestressed steel tube concrete pipe) and its manufacturing method.

[0037] Add successively the E-20 bisphenol A type epoxy resin of 1 weight part, the xylene of 0.23 weight part, the butanol of 0.11 weight part, the methyl ethyl ketone of 0.05 weight part, the coal tar pitch resin of 0.75 weight part in the stainless steel bucket liquid, 0.27 parts by weight of chlorinated ethylene vinyl acetate copolymer, 0.05 parts by weight of precipitated barium sulfate, 0.01 parts by weight of sericite powder, 0.008 parts by weight of talcum powder, and organic bentonite of 0.015 parts by weight, dispersed at a high speed for 0.5 hour, and then Grind with a sand mill for 1 h. With the product after grinding, add the coupling agent 201 of 0.008 weight part, the Ciba of 0.011 weight part successively 3650 additives and 0.008 parts by weight of silicone defoamer, and then disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com