Dew point corrosion resistant composition, hot working equipment, and preparation method of dew point corrosion resistant coating

A dew point corrosion and composition technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as dew point corrosion of thermal power equipment, and achieve the effects of high construction efficiency, high elasticity and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 8 and comparative example 1 to 2

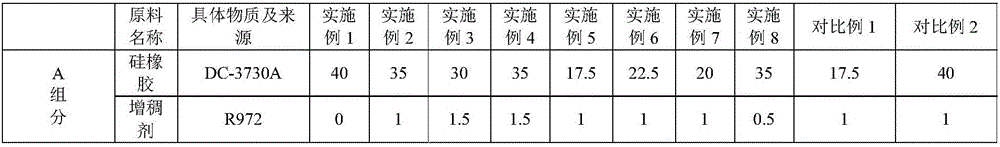

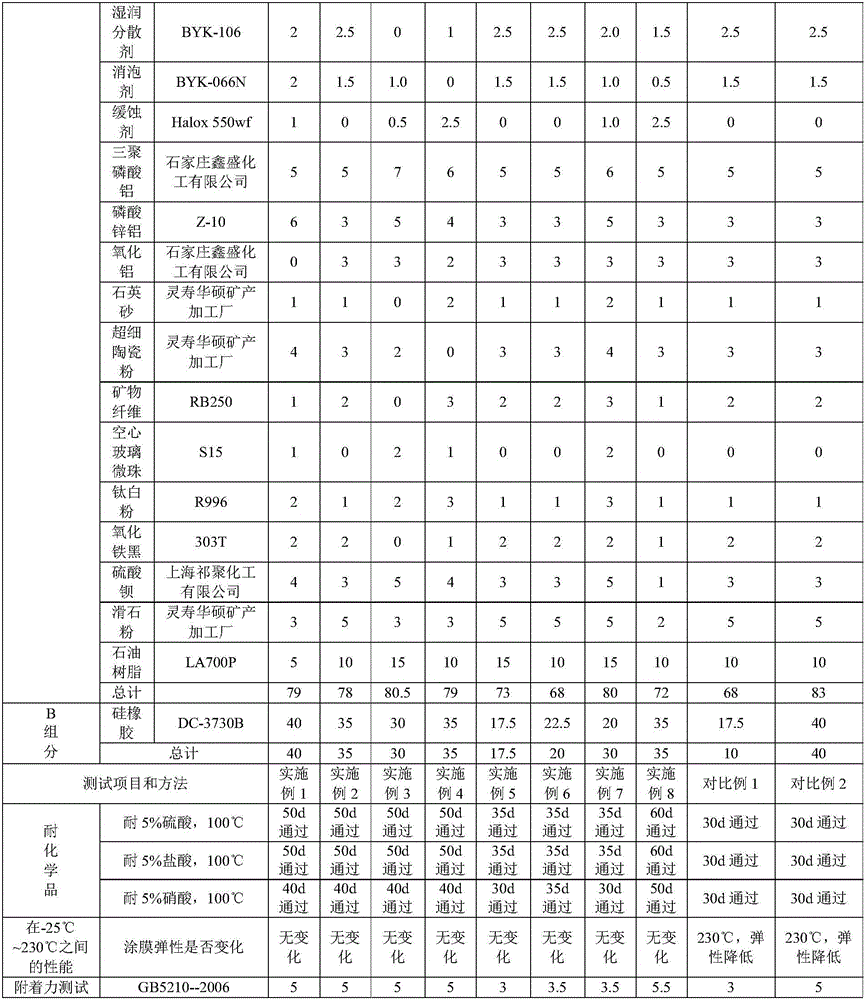

[0041] The composition of the anti-dew point corrosion composition is shown in Table 1

[0042] Fully mix the components of component A according to the proportion, disperse and grind into a uniform paste, and mix component A and component B before construction to obtain the anti-dew point corrosion coating corresponding to the embodiment.

[0043] The anti-dew point corrosion coatings of each embodiment were applied to the furnace body of the tubular heating furnace by scraping, so that the film thickness was between 1 and 2 mm.

[0044] Table 1

[0045]

[0046]

[0047] As can be seen from the data in Table 1, the coating formed by the anti-dew point corrosion composition of the present application can effectively improve the corrosion resistance of the dew point, and at 100°C, it can respectively resist 5% sulfuric acid, 5% hydrochloric acid, It is resistant to 5% nitric acid for more than 30 days. At the same time, the elasticity of the coating film does not change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com