Blue-light fluorescent powder in LED device for treatment of neonatal jaundice, and synthetic method thereof

A synthesis method and technology for blue phosphors, which are applied in the field of rare earth doped phosphors, can solve the problems of great harm to newborns, are not environmentally friendly, unfavorable to health, etc., and achieve short synthesis time, simple synthesis method, and improved energy utilization and efficiency. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of blue fluorescent powder

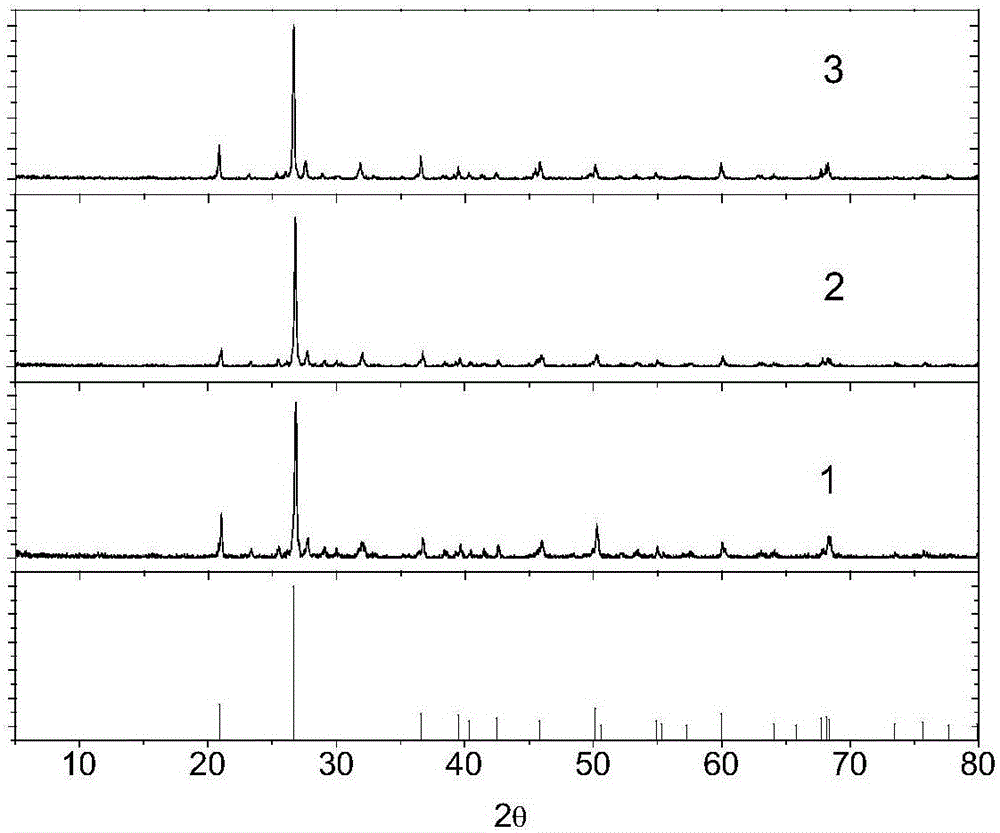

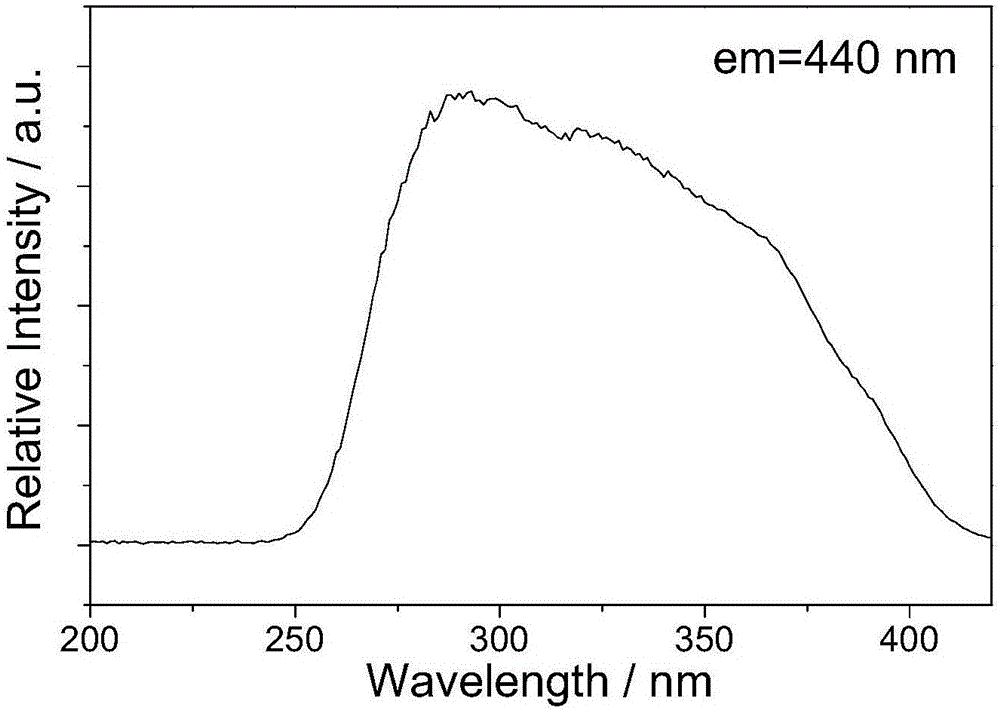

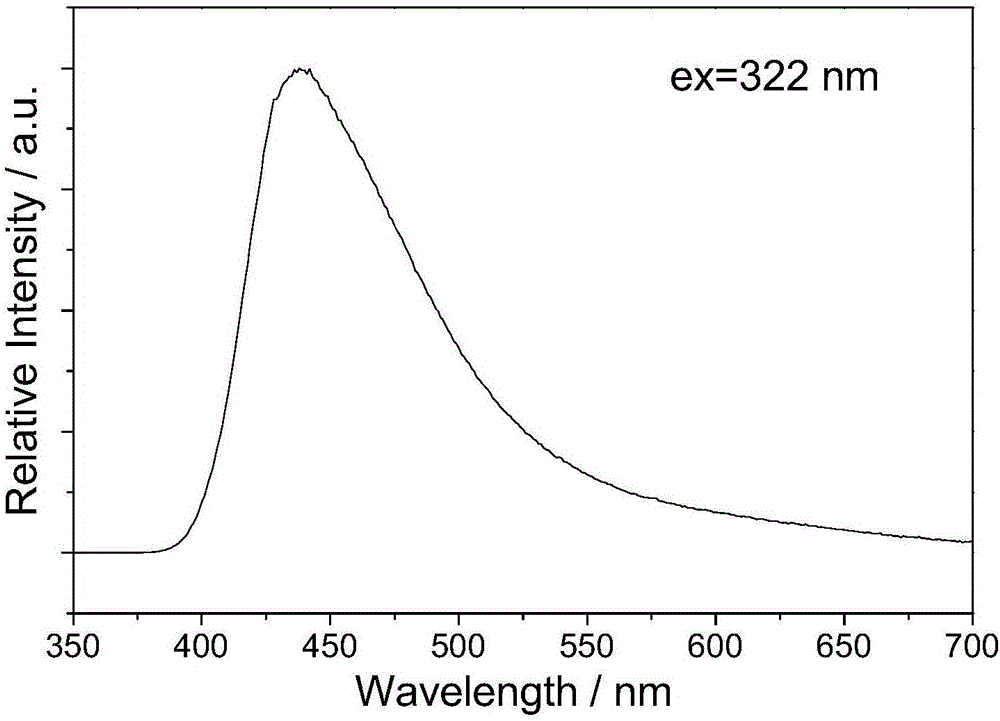

[0018] 0.01mol of MgO, 0.02mol of NH 4 Cl, 0.03mol of SiO 2 and 1.2×10 —4 mol (0.3mol%) of Eu 2 o 3 Grind in an agate mortar for 1 hour until well mixed. Put it into a ceramic crucible, then heat it to 1000°C in a high-temperature furnace, keep it warm for 2 hours, and then cool it down naturally. After taking out the sample, put it into an agate mortar, and then add 0.02mol of NH 4 Cl, grind until thoroughly mixed. Then put it into a ceramic crucible, put it into a tubular reduction furnace, and 2 :N 2 In a reducing atmosphere with a volume ratio of 1:9, heat it to 1000°C, keep it warm for 2 hours, then cool it naturally, take it out and grind it for subsequent testing. The XRD diffraction peaks of the product are as figure 1 Shown; fluorescence excitation spectrum as figure 2 Shown; fluorescence emission spectrum as image 3 Shown; Fluorescence emission variable temperature spectrum as Figure 4 ...

Embodiment 2

[0019] Embodiment 2: the preparation of blue fluorescent powder

[0020] 0.01mol of MgO, 0.02mol of NH 4 Cl, 0.03mol of SiO 2 and 2.4×10 —4 mol (0.6mol%) of Eu 2 o 3 Grind in an agate mortar for 1 hour until well mixed. Put it into a ceramic crucible, then heat it to 1000°C in a high-temperature furnace, keep it warm for 2 hours, and then cool it down naturally. After taking out the sample, put it into an agate mortar, and then add 0.02mol of NH 4 Cl, grind until thoroughly mixed. Then put it into a ceramic crucible, put it into a tubular reduction furnace, and 2 :N 2 In a reducing atmosphere with a volume ratio of 1:9, heat it to 1000°C, keep it warm for 2 hours, then cool it down naturally, take it out and grind it for subsequent testing. The XRD diffraction peaks of the product are as figure 1 shown. Such as figure 1 As shown in the middle line 2, all the diffraction peaks can correspond to the standard peaks of the α-quartz structure at the bottom (JCPDS No.46-...

Embodiment 3

[0021] Embodiment 3: the preparation of blue fluorescent powder

[0022] 0.01mol of MgO, 0.02mol of NH 4 Cl, 0.03mol of SiO 2 and 1.2×10 —4 mol (0.3mol%) of Eu 2 o 3 Grind in an agate mortar for 1 hour until well mixed. Put it into a ceramic crucible, then heat it to 900°C in a high-temperature furnace, keep it warm for 2 hours, and then cool it down naturally. After taking out the sample, put it into an agate mortar, and then add 0.02mol of NH 4 Cl, grind until thoroughly mixed. Then put it into a ceramic crucible, put it into a tubular reduction furnace, and put it in the H 2 :N 2 In a reducing atmosphere with a volume ratio of 2:8, heat it to 900°C, keep it warm for 1.5 hours, then cool it naturally, take it out and grind it for subsequent testing. The XRD diffraction peaks of the product are as figure 1 shown. Such as figure 1 As shown in the middle line 3, all the diffraction peaks can correspond to the standard peak of the α-quartz structure at the bottom (JC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com