Dioxin treatment system of hazardous waste incineration furnace

A treatment system and incinerator technology, applied in the field of environmental protection equipment, can solve the problems of not meeting environmental protection requirements and less dioxin treatment, and achieve the effects of good treatment effect, good treatment effect and wide treatment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

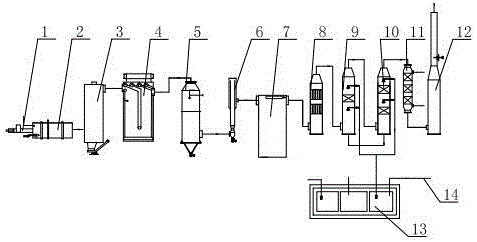

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, the hazardous waste incinerator system usually includes several parts such as waste pretreatment system, feeding system, incineration system, and flue gas purification treatment system. The waste pretreatment system includes waste pretreatment and feeding procedures. Industrial hazardous waste is transported to the warehouse of the disposal center by special vehicles. The materials that need to be crushed are crushed by the crusher, and after compatibility, they are transported to the kiln head on the operation platform by the crane. The feed port is sent to the rotary kiln 2 by the hydraulic pusher device 1 after the feed port of the kiln head passes through the two-stage hydraulic sliding door.

[0015] The incineration system consists of a rotary kiln 2, a second combustion chamber 3, slag discharge an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com