Diesel engine full-dimension SCR catalytic reactor performance test platform based on tail gas simulation

A technology of SCR catalyst and test platform, which is applied in the field of full-size SCR catalyst performance test platform of diesel engine based on exhaust gas simulation, can solve the problems of poor repeatability of test process, complicated adjustment of test conditions, long test cycle, etc., and achieves convenient manual operation. and automated testing, less internal and external interference factors, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

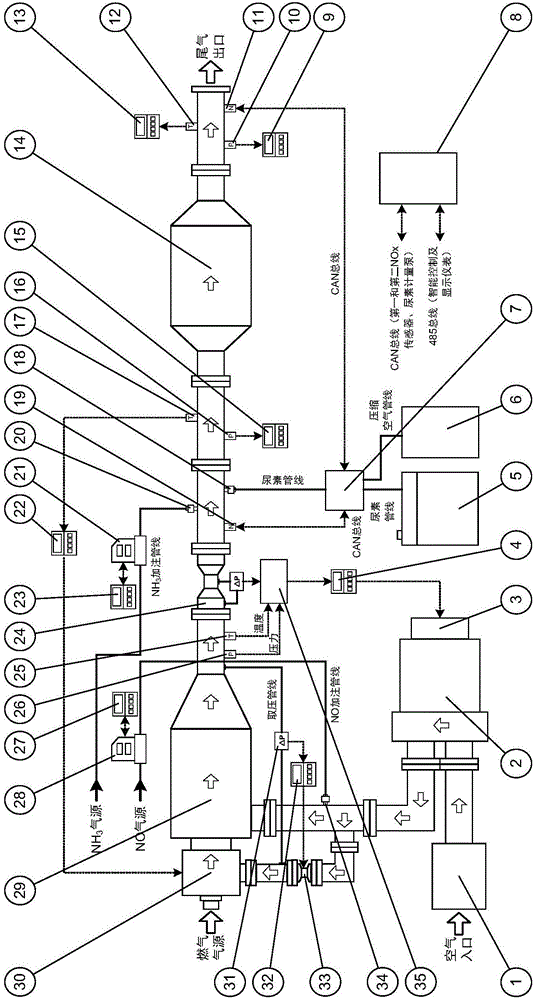

[0022] The present invention will be further described below in conjunction with the drawings.

[0023] Such as figure 1 As shown, a diesel engine full-scale SCR catalyst performance test platform based on exhaust gas simulation, including air supply system, combustion heating system, mixed filling system, urea injection system, and signal acquisition and control system, can flexibly simulate diesel engine exhaust flow and exhaust temperature The NOx conversion efficiency and pressure drop of the full-size SCR catalyst used for diesel engine aftertreatment are measured with key exhaust gas components, and the temperature characteristics, ammonia nitrogen ratio characteristics, space velocity characteristics and pressure drop characteristics of the full-size SCR catalyst are fully obtained.

[0024] The air supply system includes air filter 1, high-pressure main fan 2, inverter 3, first temperature sensor 25, first pressure sensor 26, Venturi flowmeter and supporting differential pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com