Hydroxyapatite-coating PRB filling material and preparing method and underground-water uranium removing application method thereof

A hydroxyapatite and filling material technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problem of reduced service life of osmotic reaction grids, unusable grids for powders, low adsorption capacity, etc. problems, to achieve the effect of ensuring stability and uniformity, stable coating quality, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

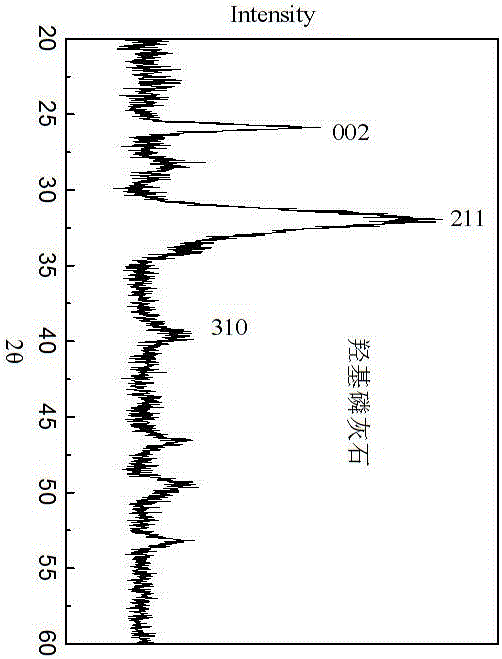

[0031] Take 240 mL, the concentration is 0.25 mol / L H 3 PO 4 The solution is placed in a beaker, and the concentration of 0.25mol / l NH 3 ·H 2O solution into the beaker to adjust the pH value to 10, add crushed and screened rocks, pebbles, coarse sand and other inert materials can be one or more, the added particle size is greater than 100 mesh, stir evenly; 100 mL concentration is 1 mol / l Ca(NO 3 ) 2 4H 2 The O solution was slowly added to the beaker with constant stirring, and NH was continuously added during the reaction. 3 ·H 2 O solution to keep the pH value of the reaction solution constant to 10, let it stand for 24 h, and remove the reaction solution to obtain the hydroxyapatite-coated PRB active filler. In the hydroxyapatite-coated PRB active filler, hydroxyapatite and The composition mass ratio of the inert material is 0.1-0.5:1.

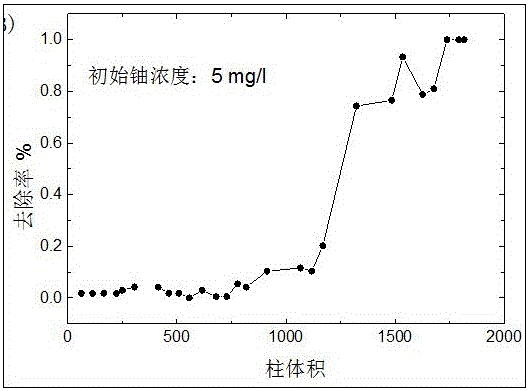

[0032] Fill the filler into a PRB simulation reaction column with a height of 200 mm and an inner diameter of 50 mm, and the urani...

Embodiment 2

[0037] Above the groundwater flow channel of a uranium mine tailings pond, the sand-bearing layer was dug out, rocks, pebbles, coarse sand, etc. were crushed and sieved, passed through a 100-mesh sieve, and the remaining sieved was taken for later use. Prepare 0.25 mol / l phosphoric acid solution, add 0.25 mol / l NH 3 ·H 2 O solution to adjust the pH to 10±1. Put rocks, pebbles, coarse sand, etc. above 100-mesh sieve into the mixture of phosphoric acid and ammonia water in a rated ratio, and add Ca(NO 3 ) 2 solution, and NH was continuously added during the reaction 3 ·H 2 O solution to keep the pH value of the reaction solution constant to 10, let it stand for 24 h, and remove the reaction solution to obtain the hydroxyapatite-coated PRB active filler, and finally control the mass ratio of hydroxyapatite to inert material to be 0.3: 1.0.

[0038] Fill the filler into the PRB reaction wall with a length of 5 m, a width of 5 m, and a thickness of 1 m, and sink it into the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com