Method and device for cooperative uptake of sulfur dioxide by discharge plasmas

A discharge plasma, sulfur dioxide technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as large equipment investment, low sulfur dioxide absorption effect, and large water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

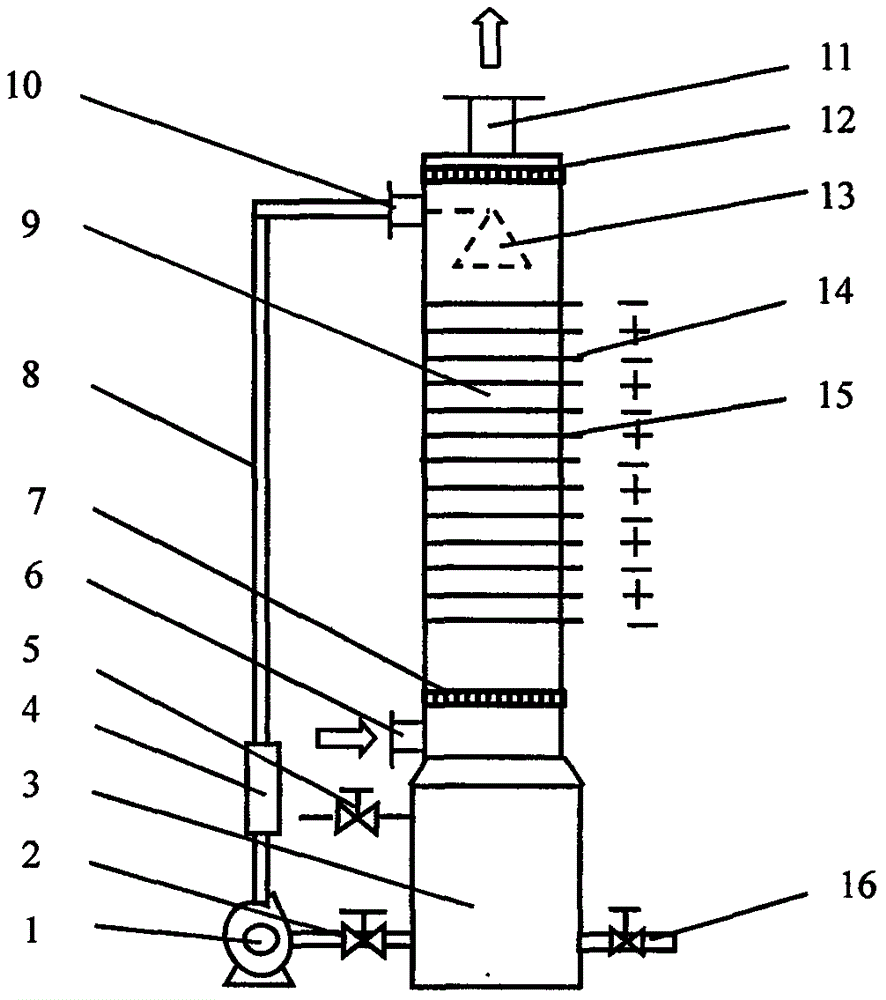

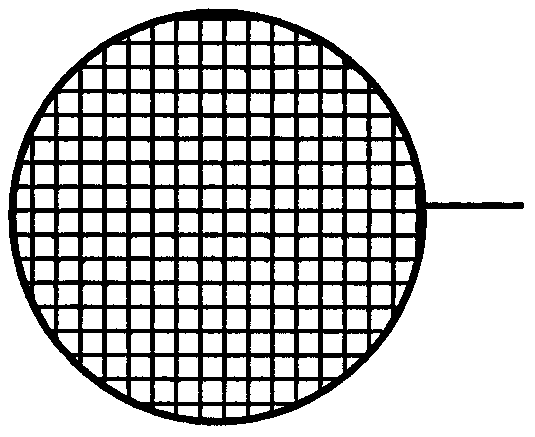

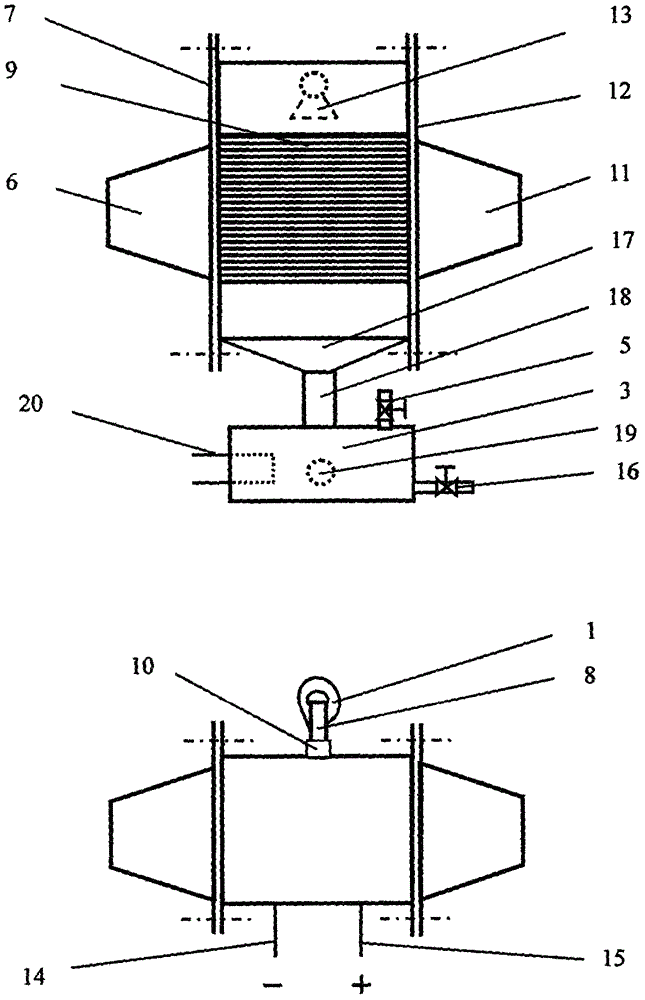

[0020] Embodiment 1: A kind of discharge plasma cooperative absorption sulfur dioxide device according to the present invention is as figure 1 shown. The device is cylindrical, the material of the cylinder is PP, the external dimensions are Φ150mm×1200mm, and it is placed vertically. electrode as figure 2 The disc-shaped mesh electrode, the electrode material is nickel-chromium stainless steel, punched and formed, the mesh is rectangular, the electrode size is Φ140mm×2mm, the single hole size is 10mm×10mm, and the distance between electrodes is about 15mm, a total of 12 groups . The electrode power supply methods are DC, pulse and AC respectively. The DC and AC voltages are both about 6kV, the AC frequency is about 50Hz, the pulse voltage is about 8kV, and the pulse frequency is about 50Hz. When DC and pulse power supply, the other electrode is grounded. All about 100W.

[0021] The treatment process is to enter the air flow of sulfur dioxide gas from the gas inlet 6 throug...

Embodiment 2

[0023] Embodiment 2: when air temperature is respectively 60, 100, 150 and 180 ℃, power supply mode is direct current, and other experimental conditions are the same as embodiment 1, and the outlet concentration that obtains sulfur dioxide is respectively 53mg / m 3 、61mg / m 3 , 84mg / m 3 and 103mg / m 3 . When the temperature of the air flow is 60°C, the air flow is firstly dehumidified by a solid calcium chloride or magnesium sulfate packed tower, and the relative humidity of the gas after dehumidification is about 40%, and then the above process is carried out to obtain an outlet concentration of sulfur dioxide of about 45mg / m 3 .

Embodiment 3

[0024] Example 3: The concentration of sulfuric acid in the initial absorption liquid was 1%, 10% and 30%, respectively, the gas inlet temperature was 90°C, the power supply was pulsed, and other experimental conditions were the same as in Example 1. The outlet concentration of sulfur dioxide obtained is 275mg / m 3 、212mg / m 3 and 96mg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com