Method and device for preparing nano-TiO2 functionalized micro-/nano-dispersion by supercritical CO2 fluid method

A supercritical, functionalized technology, applied in chemical instruments and methods, colloidal chemistry, colloidal chemistry, etc., can solve problems such as general dispersion conditions, and achieve the effect of preventing agglomeration and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

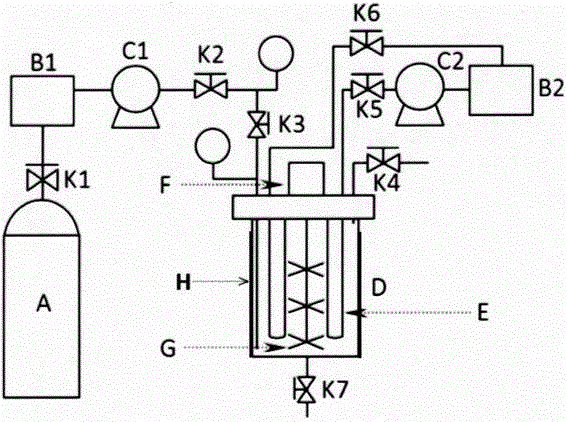

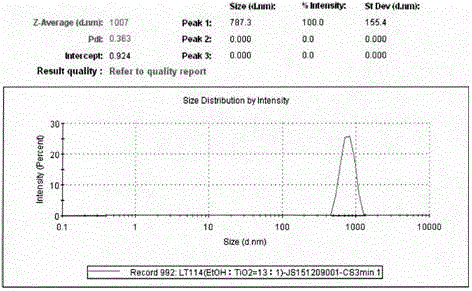

[0032] Embodiment 1: (1) take nanometer TiO 2 Powder (P25) 30g, absolute ethanol 386.1g, acetylacetone 2.1g, Triton X-1001.5g, copper phthalocyanine / dichloromethane mixed solution 0.30g (mass ratio of copper phthalocyanine / dichloromethane is 1 : 1, stirred and mixed in advance at normal temperature and pressure for 1 hour, the following examples are the same), added in the reactor D, after the reactor was sealed, heated to 45°C, stirred for 30min, and the rotating speed was 300rpm.

[0033] (2) The valve K1 will be opened, and the CO 2 into CO 2 Refrigerate to 5-6°C in the refrigerator, open the valve K2 after boosting by the booster pump, CO 2 The liquid is passed into the reactor D through the valve K3, and the supercritical temperature is kept at 45°C. After the pressure of the reactor reaches 8.5MPa, the valves K2 and K3 are closed, the stirring speed is 150-200rpm, and the supercritical time is 20min;

[0034] (3) Open the valve K5 or K6, feed 22-25°C circulating cooli...

Embodiment 2

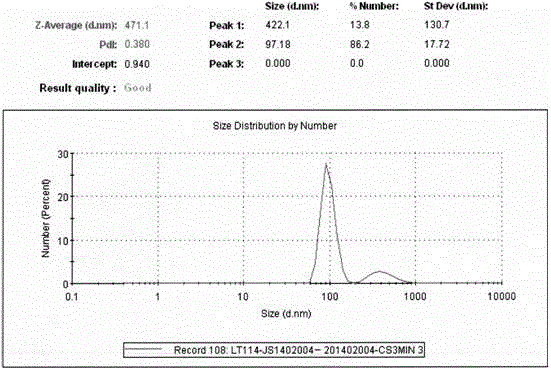

[0035] Embodiment 2: (1) take by weighing nanometer TiO Powder (P25) 30g, dehydrated alcohol 382.1g, acetylacetone 4.2g, Triton X-1003.0g, copper phthalocyanine / dichloromethane mixed solution 0.30g, Add it into the reaction kettle D. After the reaction kettle is sealed, heat it to 45°C, stir for 30min, and rotate at 300rpm. Obtain the functionalized TiO of embodiment 2 by (2) and (3) steps in embodiment 1 2 micro-nano dispersion. Contrast the amount of surfactant on nano-TiO 2 The influence of the particle size and distribution of the agglomeration state of the agglomeration.

Embodiment 3

[0036] Embodiment 3: (1) take nanometer TiO 2 65g of powder (P25), 381.55g of absolute ethanol, 4.55g of acetylacetone, 3.25g of Triton X-100, and 0.65g of copper phthalocyanine / dichloromethane mixture were added to reactor D. After the reactor was sealed, , heated to 45°C, stirred for 30min, and the rotation speed was 300rpm. Obtain the functionalized TiO of embodiment 3 by (2) and (3) steps in embodiment 1 2 micro-nano dispersion. Contrast Nano TiO 2 The powder concentration (14.28%) on nano TiO 2 The effect of particle size and distribution on the state of agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dispersed particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com