Preparation method of nitrogen-doped nickel/carbon high-performance ethanol oxidation catalyst

A technology of ethanol oxidation and nitrogen doping is applied in the field of preparation of nickel/carbon high-performance ethanol oxidation catalyst, which can solve the problems of high price, restriction of large-scale commercial application, short operating life and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

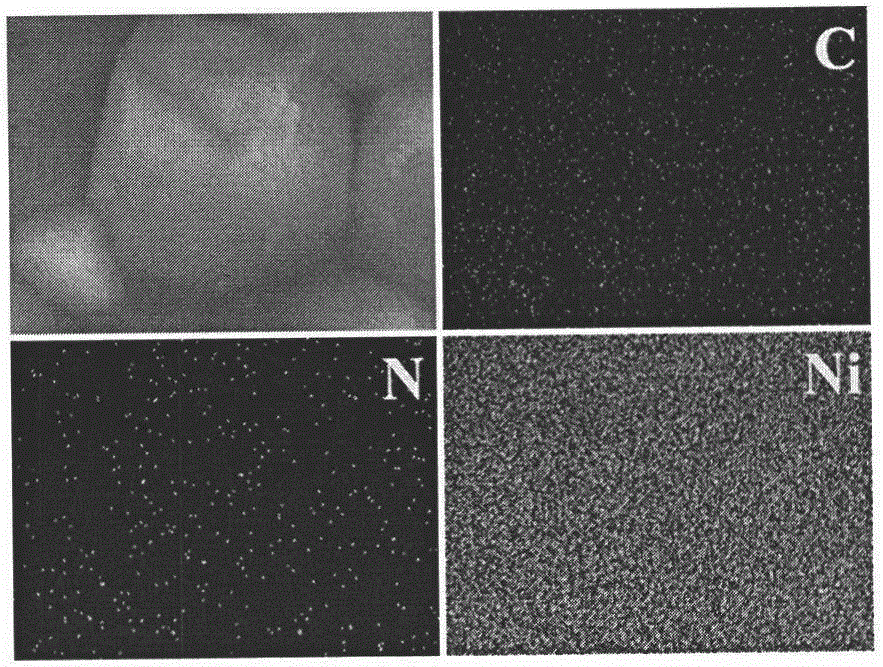

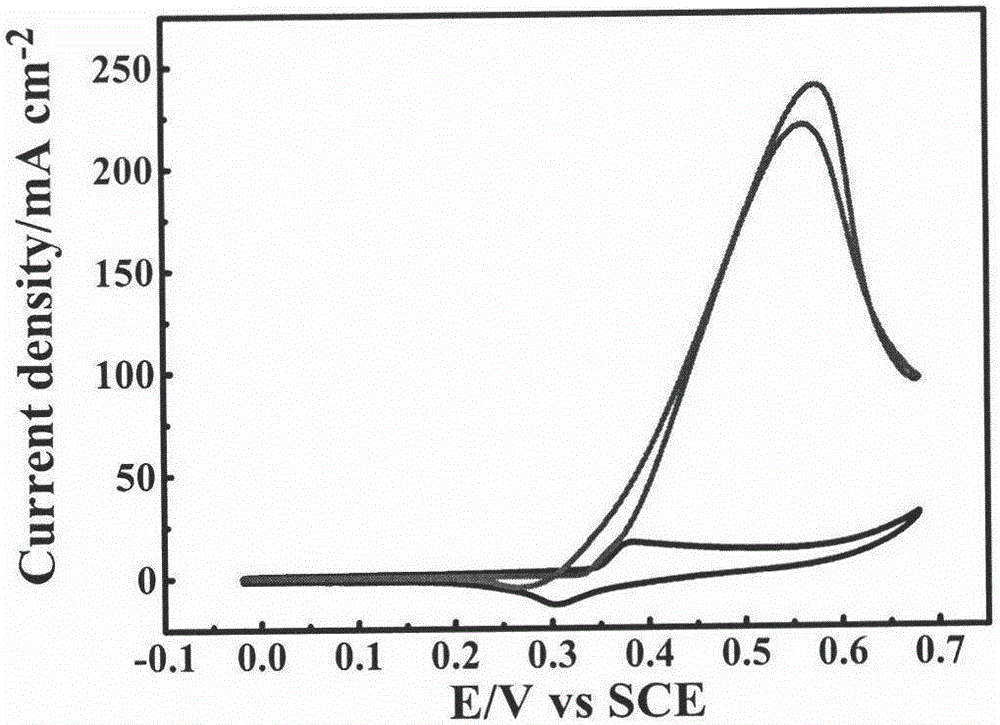

[0012] A kind of nitrogen-doped nickel / carbon high-performance ethanol oxidation catalyst preparation method, comprises the steps: 2.0g glucose, 2.3g urea, 0.5g nickel acetate and 50ml water are respectively placed in 100ml beaker, stirred at room temperature for 30min, Dry at 80°C for 12 hours; then raise the temperature to 800°C at a rate of 3°C / min under a nitrogen atmosphere, and keep the temperature at the highest temperature for 2 hours; then naturally cool down to room temperature under a nitrogen atmosphere; The nickel nitrogen / carbon high-performance ethanol oxidation catalyst was obtained by drying at ℃ for 2 hours. figure 1 It is the EDAX diagram of the nitrogen-doped nickel / carbon high-performance ethanol oxidation catalyst. The spherical structure is clearly seen from the diagram, and the carbon, nitrogen and nickel elements are evenly distributed. figure 2 XRD pattern of the nitrogen-doped nickel / carbon high-performance ethanol oxidation catalyst, it can be seen...

Embodiment 2

[0014] A method for preparing a nitrogen-doped nickel / carbon high-performance ethanol oxidation catalyst, comprising the steps of: respectively placing 2.0g glucose, 1.8g urea, 0.5g nickel acetate and 50ml water in a 100ml beaker, stirring at room temperature for 30min, Dry at 80°C for 12 hours; then raise the temperature to 900°C at a rate of 2°C / min under a nitrogen atmosphere, and keep the temperature at the highest temperature for 2 hours; then naturally cool down to room temperature under a nitrogen atmosphere; The nickel nitrogen / carbon high-performance ethanol oxidation catalyst was obtained by drying at ℃ for 2 hours. The morphology of the catalyst thus prepared is more irregular, there is a small amount of agglomeration, and the distribution is uneven, and relative to Example 1, the current density decreases to some extent (210mA cm -2 ) and the nickel nanoparticles were significantly enlarged.

Embodiment 3

[0016] A method for preparing a nitrogen-doped nickel / carbon high-performance ethanol oxidation catalyst, comprising the steps of: respectively placing 2.0g glucose, 1.8g urea, 0.5g nickel acetate and 50ml water in a 100ml beaker, stirring at room temperature for 30min, Dry at 80°C for 12 hours; then raise the temperature to 800°C at a rate of 3°C / min under a nitrogen atmosphere, and keep the temperature at the highest temperature for 2 hours; then naturally cool down to room temperature under a nitrogen atmosphere; The nickel nitrogen / carbon high-performance ethanol oxidation catalyst was obtained by drying at ℃ for 2 hours. Compared with Example 1, the morphology of the catalyst thus prepared has decreased current density, increased particle size, which is not conducive to oxidation reaction, and reduced nitrogen functional groups, without more active sites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com