Method for producing high-performance iron oxide red with hydrothermal ultra-fine crystal seeds

A technology of iron oxide red and ultra-fine crystals, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of long process for treating ammonia nitrogen in the filtrate, high equipment performance requirements, and high cost, and meet the production equipment performance requirements. High, good quality, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

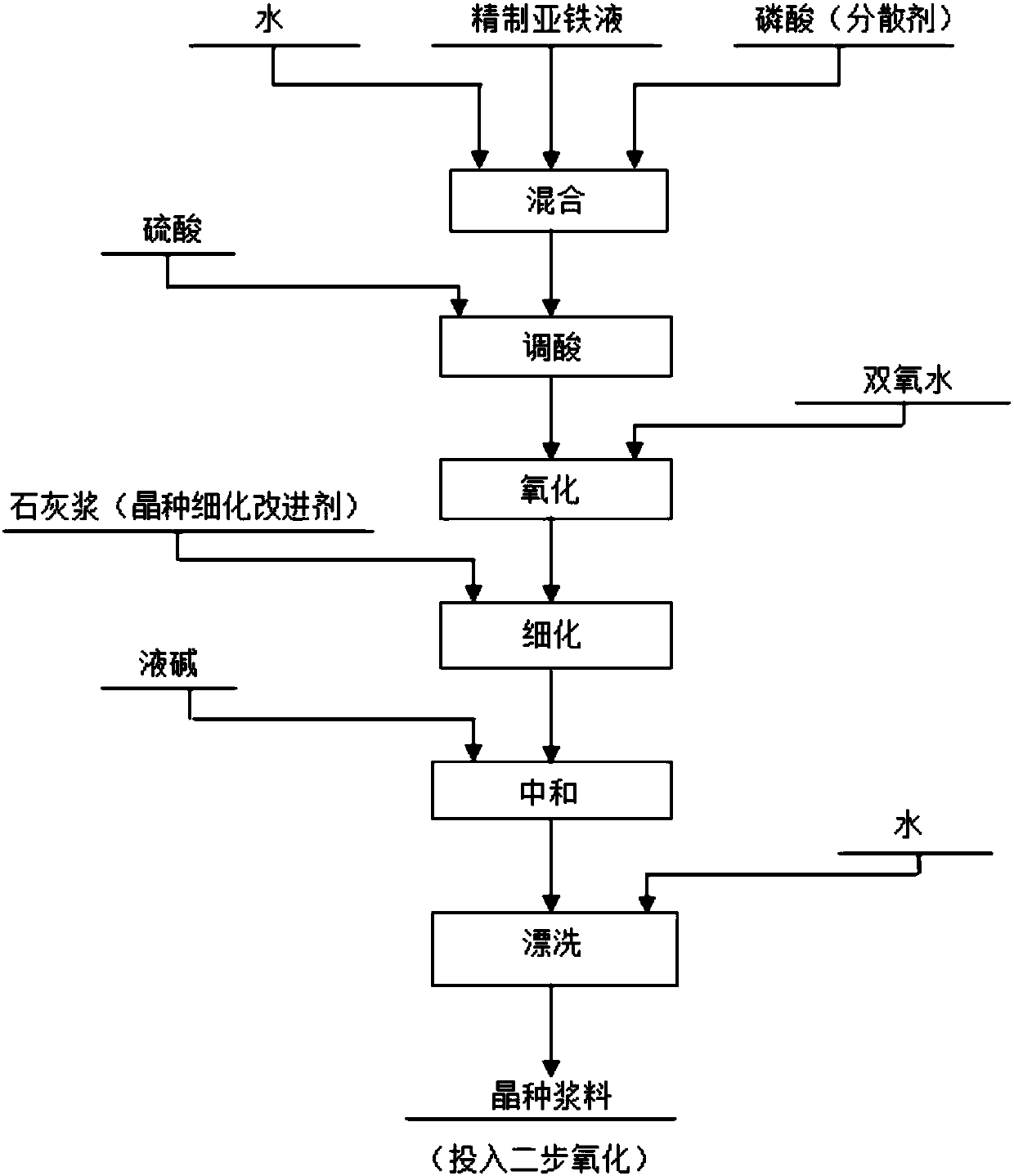

[0035] Step 1, in parts by weight, take 600 parts of water and stir, mix 1 part of phosphoric acid and 100 parts of ferrous sulfate heptahydrate to obtain the first mixed solution, adjust the pH value of the first mixed solution to 1 with sulfuric acid ;

[0036] Step 2, continue to stir, add 21 parts of hydrogen peroxide in parts by weight, at this moment, potassium ferricyanide detector detects Fe 2+ fully oxidized;

[0037] Step 3, heat up to 70°C, add 1 part of lime slurry in parts by weight, stir to obtain the slurry, adjust the pH value of the slurry to 3 with liquid caustic soda;

[0038] Step 4, feed air into the slurry, rinse with water after stirring until there is no SO in the supernatant of the slurry 2- ;

[0039] Step 5, performing two-step oxidation on the rinsed slurry, then rinsing, drying, and crushing to obtain high-performance iron oxide red.

Embodiment 2

[0041] Step 1, in parts by weight, take 1000 parts of water and stir, mix 5 parts of phosphoric acid and 100 parts of ferrous sulfate heptahydrate to obtain the first mixed solution, adjust the pH value of the first mixed solution with sulfuric acid to 3.5 ;

[0042] Step 2, continue to stir, add 40 parts of hydrogen peroxide in parts by weight, at this time, the potassium ferricyanide detection agent detects Fe 2+ fully oxidized;

[0043] Step 3, heat up to 90°C, add 10 parts of lime slurry in parts by weight, stir to obtain the slurry, adjust the pH value of the slurry to 4 with liquid caustic soda;

[0044] Step 4, feed air into the slurry, rinse with water after stirring until there is no SO in the supernatant of the slurry 2- ;

[0045] Step 5, performing two-step oxidation on the rinsed slurry, then rinsing, drying, and crushing to obtain high-performance iron oxide red.

Embodiment 3

[0047] Step 1, in parts by weight, take 800 parts of water and stir, mix 2 parts of phosphoric acid and 100 parts of ferrous sulfate heptahydrate to obtain the first mixed solution, adjust the pH of the first mixed solution with sulfuric acid to be 2 ;

[0048] Step 2, continue to stir, add 30 parts of hydrogen peroxide in parts by weight, at this time, the potassium ferricyanide detection agent detects Fe 2+ fully oxidized;

[0049] Step 3, heat up to 75°C, add 5 parts of lime slurry in parts by weight, stir to obtain the slurry, adjust the pH value of the slurry to 3 with liquid caustic soda;

[0050] Step 4, feed air into the slurry, rinse with water after stirring until there is no SO in the supernatant of the slurry 2- ;

[0051] Step 5, performing two-step oxidation on the rinsed slurry, then rinsing, drying, and crushing to obtain high-performance iron oxide red.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tinctorial strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com