Method for preparing sulphate aluminium cement through phosphogypsum

A sulphoaluminate cement and a technology for producing sulphoaluminate, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve problems such as ineffective utilization of phosphogypsum, high production costs, and environmental pollution. Achieve good economic and environmental benefits, low production costs, and simple process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] a. Preparation of cement raw meal:

[0013] Dosing according to the following parts by mass: 65-80 parts of phosphogypsum, 18-28 parts of bauxite, 2-4 parts of steel slag, 3-5 parts of anthracite; mix all components, grind and homogenize to get raw cement material;

[0014] b. Preparation of cement clinker:

[0015] Calcining the cement raw meal prepared in step a at 1250-1300° C. for 30-40 minutes to obtain cement clinker;

[0016] c. Preparation of sulphoaluminate cement:

[0017] The cement clinker obtained in step b is ground again to obtain sulphoaluminate cement.

[0018] According to the present invention, preferably, the fineness of each component in step a after grinding is 120-180 mesh;

[0019] Preferably, Al in the described bauxite 2 o 3 The mass fraction is 55-68%, further preferably 62%;

[0020] Preferably, the phosphogypsum is phosphogypsum hemihydrate.

[0021] According to the present invention, preferably, batching is carried out according to...

specific Embodiment approach

[0052] The present invention will be further described in detail below in conjunction with specific embodiments, but is not limited thereto.

[0053] Phosphogypsum in each of the following examples is taken from the hemihydrate gypsum produced by the new wet-process phosphoric acid of Jinzheng Da Nuo Taier Chemical Co., Ltd., its main components are shown in Table 1, and the main components of steel slag are shown in Table 2 below, aluminum Bauxite was produced in Shijiazhuang, Hebei, and its main components are shown in Table 3.

[0054] Table 1: Main components and contents of phosphogypsum

[0055] components CaO SO 3

Fe 2 o 3

Al 2 o 3

SiO 2

content% 36.96 52.63 0.15 0.57 1.97

[0056] Table 2: Main components and content of steel slag

[0057] components CaO Fe 2 o 3

SiO 2

Al 2 o 3

SO 3

content% 47.45 18.75 16.43 5.31 /

[0058] Table 3: Main composition and content...

Embodiment 1

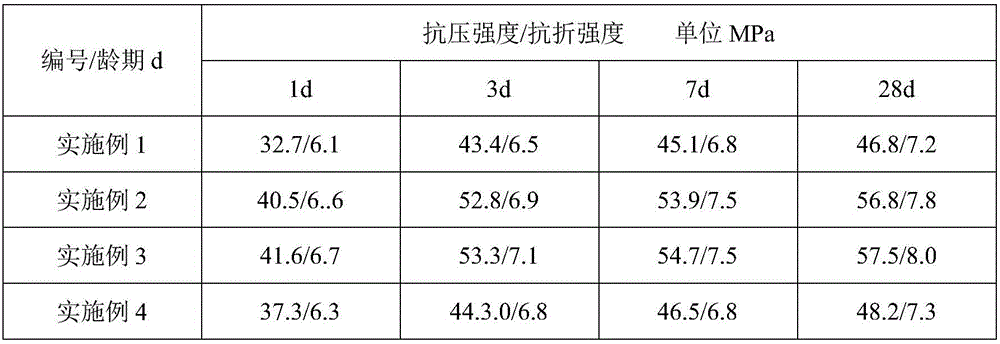

[0061] Dosing according to the following parts by mass: 65 parts of phosphogypsum, 28 parts of bauxite, 4 parts of steel slag, and 3 parts of anthracite; then grind and mix each component until the fineness is 120 meshes to obtain cement raw meal; The prepared cement raw meal is placed in a rotary kiln and calcined at 1250°C for 30 minutes to obtain cement clinker. After calcining, the tail gas containing sulfur dioxide is sent to the sulfuric acid preparation system to prepare sulfuric acid; the fired cement clinker is ground again to 350m 2 / kg, the sulphoaluminate cement product can be obtained, and the mechanical properties of the obtained sulphoaluminate cement are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com