Foam stabilizer composition, application of foam stabilizer composition, foam cement slurry, additive composition of foam cement slurry and applications of foam cement slurry and additive composition of foam cement slurry

The technology of a composition and a foam stabilizer is applied in the field of foamed cement slurry and its additive composition, which can solve the problems of low-density foamed cement stone, high permeability of foamed cement stone, poor foam stability and the like, and achieves high foam stability, The effect of high compressive strength and low permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0062] This example serves to illustrate the foam stabilizer composition.

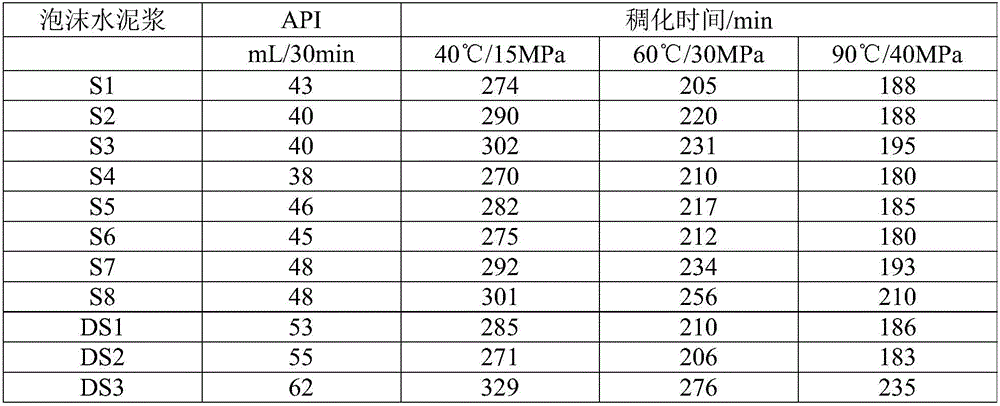

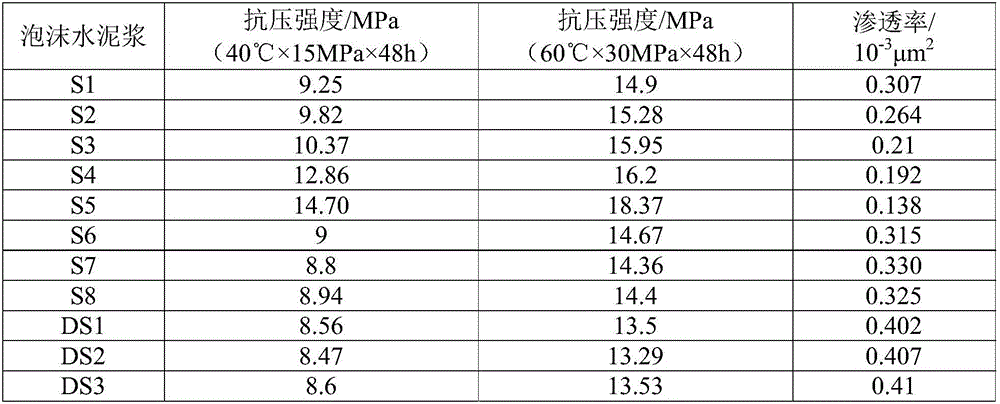

[0063] According to the formula shown in Table 1, the listed amine oxide compounds, betaine compounds, tea saponin and appropriate water were prepared into aqueous solutions of corresponding concentrations to obtain foam stabilizers F1-F6 respectively.

Embodiment 1

[0070] This example serves to illustrate the foamed grout additive composition and foamed grout of the present invention.

[0071] (1) G grade oil well cement, sodium perchlorate gas-generating agent I, polyvinyl alcohol fluid loss reducer (the G60S fluid loss reducer brand purchased from Tianjin Zhongyou Boxing Engineering Technology Co., Ltd.) and sulfonated formaldehyde- Acetone polycondensate dispersant (the CF40 dispersant grade purchased from Tianjin Zhongyou Boxing Engineering Technology Co., Ltd.) is dry-mixed to obtain a uniformly mixed mixture;

[0072] (2) water, foam stabilizer F1, nano-reinforcing agent nano-silica sol (the solid content of this sol is 35% by weight, and the size of nano-silica is 8-15nm) and sodium lignosulfonate retarder (the solid content of this retarder is 16% by weight, purchased from the sodium lignosulfonate retarder of Shandong Gaotang Huadong Lignin Co., Ltd.) After stirring and mixing for 15s at 4000rpm, add the above-mentioned mixture ...

Embodiment 2

[0074] This example serves to illustrate the foamed grout additive composition and foamed grout of the present invention.

[0075] According to the method of foam cement slurry embodiment 1, the difference is that the gas generating agent I adopts sodium chlorite to replace sodium perchlorate, the gas generating agent II adopts hydroxylamine sulfate to replace dihydrazide carbonate, and the foam stabilizer adopts foam stabilizer F2 In place of F1, resulting in foamed cement slurry S2 with a density of 0.92 g / cm 3 , wherein, excluding solvent components, the weight ratio of cement, air-generating agent I, air-generating agent II, foam stabilizer, nano-enhancer, fluid loss reducer, dispersant, retarder and water is 100:0.85: 0.4:1.7:2.3:1.55:0.3:0.47:56.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com