Organic liquid fertilizer based on concentrated biogas slurry as well as preparation and application methods thereof

A technology of organic liquid fertilizer and concentrated biogas, applied in the direction of organic fertilizer, application, inorganic fertilizer, etc., can solve the problems of secondary salinization, high price of water-soluble fertilizer, etc., achieve stability and fertilizer efficiency improvement, improve sustainable production capacity, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

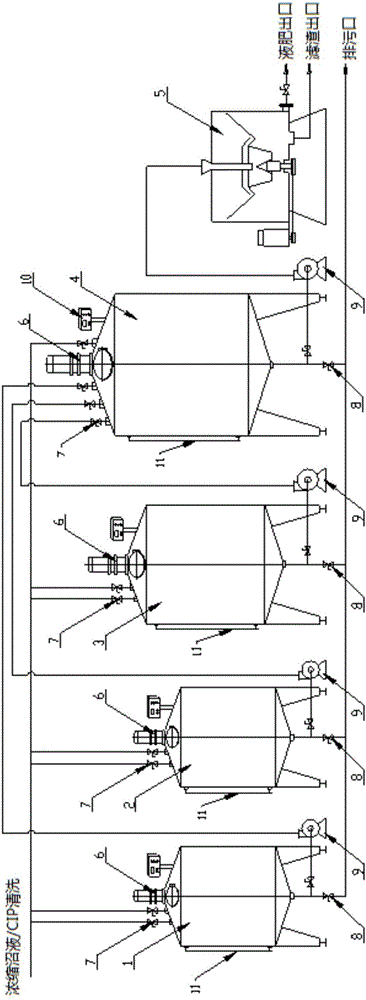

[0044] like figure 1As shown, this embodiment provides a synthetic device used to prepare the organic liquid fertilizer, which is also a process flow for preparing the organic liquid fertilizer according to the present invention. In addition to the different volumes of No. 1 to No. 3 blending reactors in the synthetic device, The remaining related configurations (including feeding port, dispersing mixer 6, feeding valve 7, discharging valve 8, thick slurry pump 9, control box 10, scale liquid level gauge 11, etc.) are the same; The configuration is basically the same as that of No. 1 to No. 3 deployment reactors, the only difference is that the volume and function are different; moreover, the control boxes 10 of each of the above reactors are the same, and are used to control the thick slurry pump 9 and electric heating of each reactor configuration. The opening of the mixer and the dispersing mixer 6, as well as the setting of time and temperature; in addition, No. 1 to No. 3...

Embodiment 2

[0046] This embodiment provides a method for preparing organic liquid fertilizer using the device described in Embodiment 1, such as figure 1 As shown, it includes the following steps:

[0047] (1) Open the feed valve 7 of the No. 1 deployment reactor, start its thick slurry pump 9, add 1000 kg of concentrated biogas slurry with a solid content of 10%, and close the feed valve 7. Start its dispersing mixer 6, open the feeding port, drop in monoammonium phosphate (11-44-0) powder raw material 850kg (85% of concentrated biogas slurry), close the feeding port, and continue to disperse and mix. Start the electric heater to heat up the temperature, wait for the temperature of the material to rise to 60°C, and maintain the temperature to continue dispersing and mixing for 30 minutes, stop heating and dispersing and mixing, and obtain an organic basic liquid fertilizer solution with a grade of [5.1-20.2-0].

[0048] (2) Open the feed valve 7 of the No. 2 deployment reactor, start th...

Embodiment 3

[0054] This embodiment provides another method for preparing organic liquid fertilizer using the device described in Embodiment 1, such as figure 1 As shown, it includes the following steps:

[0055] (1) Open the feed valve 7 of the No. 1 deployment reactor, start the thick slurry pump 9, add 1000 kg of the concentrated biogas slurry with a solid content of 20%, and close the feed valve 7. Start the dispersing mixer 6, open the feeding port, put in 600 kg of diammonium phosphate (15-42-0) powder raw material (60% of the concentrated biogas slurry), close the feeding port, and continue to disperse and mix. Start the electric heater to heat up the temperature, wait for the temperature of the material to rise to 50°C, and maintain the temperature to continue dispersing and mixing for 15 minutes, stop heating and dispersing and mixing, and obtain an organic basic liquid fertilizer solution with a grade of [5.6-15.8-0].

[0056] (2) Open the feed valve 7 of the No. 2 deployment re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com