Preparation method of photothermal self-lubricating oil gel for liquid drop remote accurate driving

A lubricating oil and photothermal technology is applied in the preparation field of photothermal self-lubricating oil gel, which can solve the problems of easy pollution of materials and high cost, and achieve the effects of low experimental condition requirements, low production cost and short preparation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

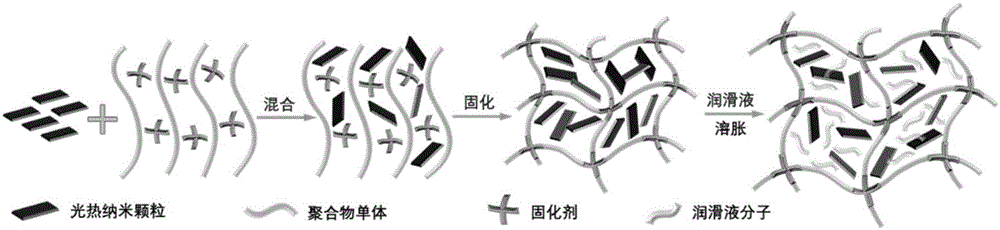

[0048] The preparation of nano-graphite sheet / polydimethylsiloxane composite photothermal self-lubricating oil gel surface, the specific steps are as follows:

[0049] The first step, the configuration of the nanographite / polydimethylsiloxane mixture:

[0050]First place the nano-graphite sheet in a vacuum drying oven at 80°C for 12 hours in a vacuum, then mix 0.579 g of nano-graphite sheet with polydimethylsiloxane (PDMS) prepolymer and its curing agent silane coupling agent in mass ratio of Mix at a ratio of 0.579:10:1, and stir mechanically at a high speed of 2200 rpm for 5 minutes to obtain a nano-graphite flake / polydimethylsiloxane mixed liquid.

[0051] In the second step, the nanographite / polydimethylsiloxane mixture is solidified:

[0052] Pour the nano-graphite flake / polydimethylsiloxane mixed solution fully mixed in the first step into the mold, and place it in a vacuum drying oven at room temperature for degassing for 30 minutes; The dimethylsiloxane mixture was c...

Embodiment 2

[0062] The preparation of the nano-ferric oxide / polydimethylsiloxane composite photothermal self-lubricating oil gel surface, the specific steps are as follows:

[0063] The first step, the configuration of nano-ferric oxide / polydimethylsiloxane mixture:

[0064] First lyophilize the oleic acid-modified nanometer iron ferric oxide alcohol dispersion for 24 hours to obtain a freeze-dried powder, then add 0.579 grams of nanometer iron ferric oxide and polydimethylsiloxane (PDMS) prepolymer and its curing agent to Mix at a mass ratio of 0.579:10:1, and stir mechanically at a high speed of 3000 rpm for 10 minutes to obtain a nano-ferric oxide / polydimethylsiloxane mixed liquid.

[0065] In the second step, the nano-ferric oxide / polydimethylsiloxane mixture is solidified:

[0066] Pour the nano-ferric oxide / polydimethylsiloxane mixed solution thoroughly mixed in the first step into a mold, and place it in a vacuum drying oven at room temperature for 1 hour for defoaming. Then, the...

Embodiment 3

[0071] The preparation of graphene / polydimethylsiloxane composite photothermal self-lubricating oil gel surface, the specific steps are:

[0072] The first step, graphene / polydimethylsiloxane mixed liquid configuration:

[0073] First place the graphene in a vacuum drying oven at 80°C for 12 hours in vacuum, then mix 0.579 grams of graphene with polydimethylsiloxane (PDMS) prepolymer and its curing agent in a mass ratio of 0.579:10:1 Proportional mixing, 2200rpm high-speed mechanical stirring for 5min, prepared graphene / polydimethylsiloxane mixed solution and solidified.

[0074] In the second step, the graphene / polydimethylsiloxane mixture is solidified:

[0075] Pour the fully mixed graphene / polydimethylsiloxane mixture into a mold, and place it in a vacuum drying oven at room temperature for vacuum defoaming for 1 hour. Then, the defoamed graphene / polydimethylsiloxane mixed solution was placed in an oven at 70° C. for 8 hours to cure.

[0076] In the third step, the cure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com