A carbon nanotube doped fracturing fluid system

A technology of carbon nanotubes and multi-walled carbon nanotubes, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as the reduction of the molecular weight of guar gum, the loss of viscosity of the solution system, and the low energy of glycosidic bonds. Achieve the effects of large performance improvement, high temperature resistance, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

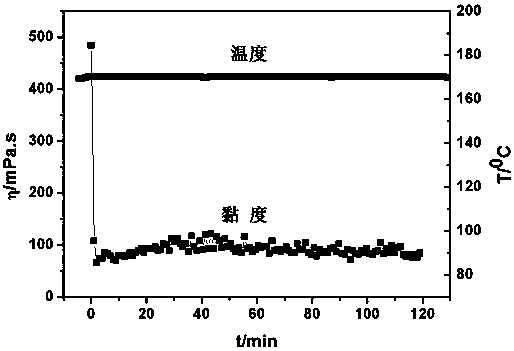

Image

Examples

Embodiment 1

[0020] The water-soluble hydroxylated carbon nanotubes and aminated carbon nanotubes were prepared according to the literature method.

[0021] In a 2L beaker, first add 985.8g of water, then add 2g of hydroxypropyl guar gum, 0.2g of hydroxylated carbon nanotubes, and 3g of drainage aid. After shearing with an emulsifying shearer for 15 minutes, a uniform solution is obtained. Add 4g slowly Borax was stirred for 3 minutes to obtain a cross-linked jelly. Finally, 5g of ammonium persulfate was added to break the gel and hydrate the fracturing fluid.

Embodiment 2

[0023] In a 2L beaker, first add 975.5g of water, then add 5g of carboxymethyl hydroxypropyl guar gum, 0.5g of aminated carbon nanotubes, and 5g of drainage aid. After cutting with an emulsifying shear for 15 minutes, a uniform solution is obtained , Slowly add 6g of boron sorbitol and stir for 3min to obtain the cross-linked jelly. Finally, add 8g of potassium persulfate to break and hydrate the fracturing fluid.

Embodiment 3

[0025] In a 2L beaker, add 957g of water, and then add 8g of hydroxypropyl guar gum, 0.4g of aminated carbon nanotubes, 0.6g of hydroxylated carbon nanotubes, and 8g of drainage aid. After cutting for 15 minutes with an emulsifying shear , To obtain a uniform solution, slowly add 6g of triethanolamine boron, stir for 3min to obtain the crosslinked jelly, and finally add 20g of ammonium persulfate to break the gel and hydrate the fracturing fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com