Strain for producing high-activity keratin hydrolase and application of strain

A keratin and hydrolase technology, applied in the field of bioengineering, can solve the problems of increasing the production cost of feather meal, difficult to degrade feather protein, poor digestion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] Preparation and formulation of keratinase

[0093] In the present invention, the keratinase based on the strain of the present invention and the preparation containing the keratinase are also provided.

[0094] In the present invention, a preferred keratinase preparation is the crude enzyme preparation of the strain of the present invention, that is, the solution obtained after the fermentation product of the strain of the present invention is centrifuged to remove solid impurities (including bacteria). The crude enzyme solution can be used directly as an enzyme preparation, or can be further processed (such as freeze-drying) to obtain a solid-state enzyme preparation.

[0095] In the enzyme preparation of the present invention, substances beneficial to maintaining enzyme activity, such as stabilizers, etc., may optionally be added.

[0096] Method for hydrolyzing keratin (application)

[0097] The present invention also provides a method for hydrolyzing (or enzymolyz...

Embodiment 1

[0121] Screening and mutagenesis of embodiment 1 bacterial strain

[0122] 1.1. Screening and isolation of strains

[0123] Take a certain amount of keratin accumulation (0.1-1g), add it into a 250ml Erlenmeyer flask containing 50mL enriched medium, shake and culture at 37°C and 180r / min for 5-7 days, and observe the color change of the medium.

[0124] The enriched culture solution was serially diluted, and the dilution was 10 -5 、10 -6 and 10 -7 The dilutions were spread on the feather meal screening plate respectively, and the grown single colonies were picked and cultured again on the screening plate for separation and purification to obtain single colonies. The single colonies obtained above were stored in test tubes for future use.

[0125] As a result, 27 different strains were screened, and their enzyme activities were within 300U / ml.

[0126] 1.2. Enzyme activity screening

[0127] Inoculate the strain obtained and preserved in the previous step into a 250ml Erl...

Embodiment 2

[0133] The optimization of embodiment 2 fermentation conditions

[0134] In this example, the culture conditions and medium were optimized for Deinococcus radiodurans J1 obtained in Example 1.

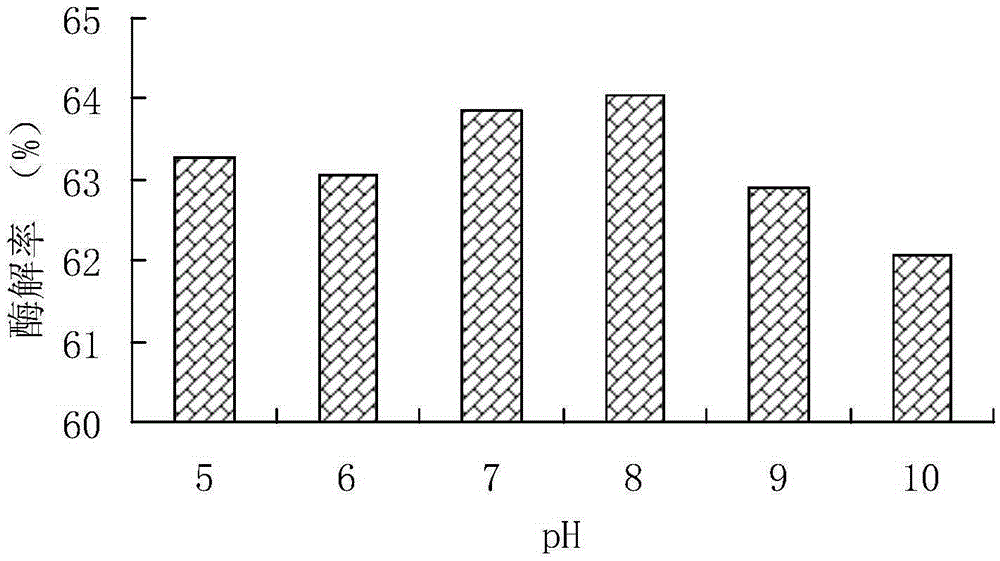

[0135] 2.1. Effect of different initial pH on enzyme production

[0136] The initial pH was set to 5, 6, 7, 8, 9, 10, and the effect of initial pH on fermentation enzyme production was investigated.

[0137] The result is as figure 2 shown. Wherein, when the pH is neutral (eg, the pH is 8), the enzymolysis rate of the feather is the highest (up to 64%), and the growth of the bacterial strain is better, which is more favorable for fermentation and enzyme production.

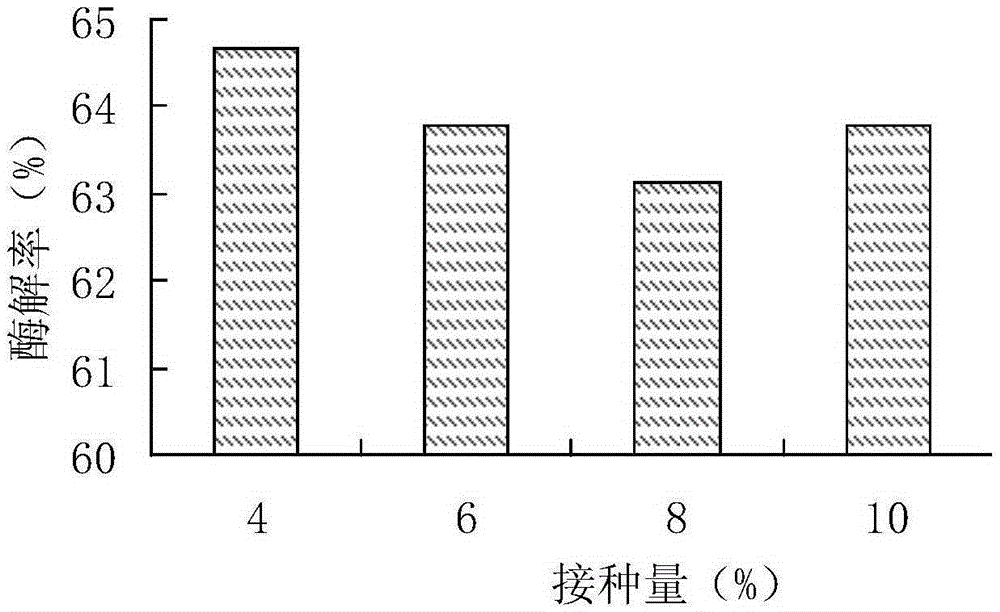

[0138] 2.2. Effect of different inoculation volumes on enzyme production

[0139] The inoculum volume was designed to be 4%, 6%, 8%, 10%, and 12%, and the influence of the inoculum volume on the growth of the strain was investigated.

[0140] The result is as image 3 shown. Among them, the enzymolysis rate of feat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com