Rotary kiln with waste heat utilization system for roasting molybdenum oxide

A rotary kiln, molybdenum oxide technology, applied in waste heat treatment, rotary drum furnace, lighting and heating equipment, etc., can solve the problems of low production capacity and low work efficiency, and achieve the effect of long service life, improved efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

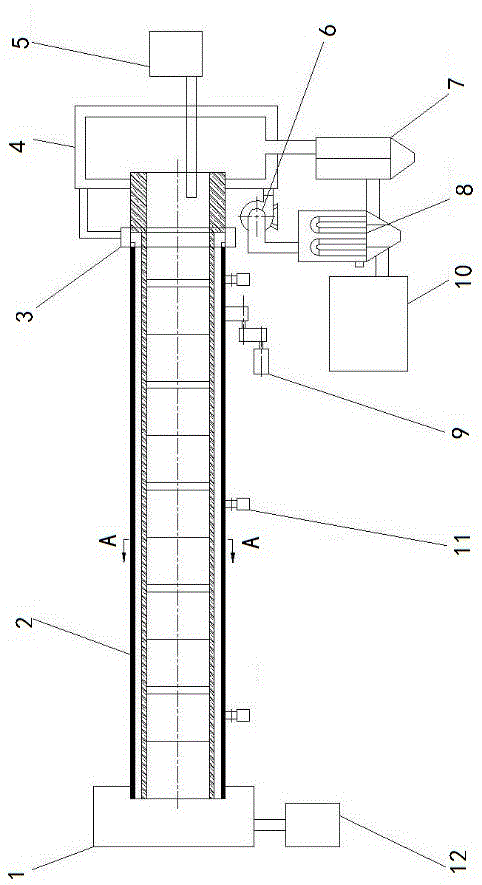

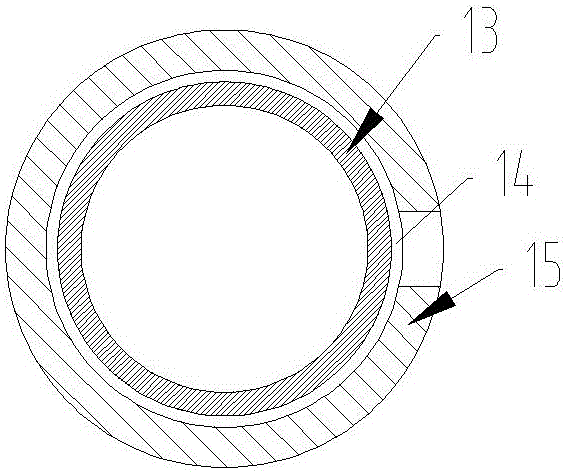

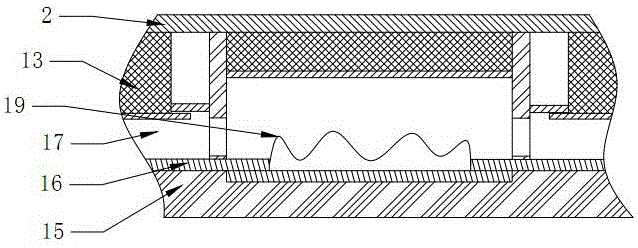

[0031] Embodiment: a kind of rotary kiln for roasting molybdenum oxide, see Figure 1 to Figure 5 The feed end is connected to the flue gas treatment system. The flue gas treatment system includes cooling equipment and dust collectors. The rotary kiln includes an insulation layer, a heat exchange layer, and a refractory layer in sequence from the outside to the inside. There is a fixing device between the insulation layer and the refractory layer. To form a heat exchange channel constituting the heat exchange layer, the air inlet of the heat exchange channel is connected to a waste heat utilization system for heat exchange with the flue gas treatment system through a rotary sealing device, and the air outlet of the heat exchange channel is connected to the inner cavity of the rotary kiln.

[0032] The reason for using two dust collectors is that the dust bag can only withstand the temperature of 200°C, so before entering the common dust collector 10, it often needs to be cooled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com