Photo-anode of dye-sensitized solar cell and preparation method of photo-anode

A technology of solar cells and dye sensitization, which is applied in the field of dye-sensitized solar cell photoanodes and its preparation, can solve the problems of low current density, limited electron transfer speed, low conductivity, etc., achieve high photoelectric conversion efficiency, improve electronic Transfer efficiency, effect of high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

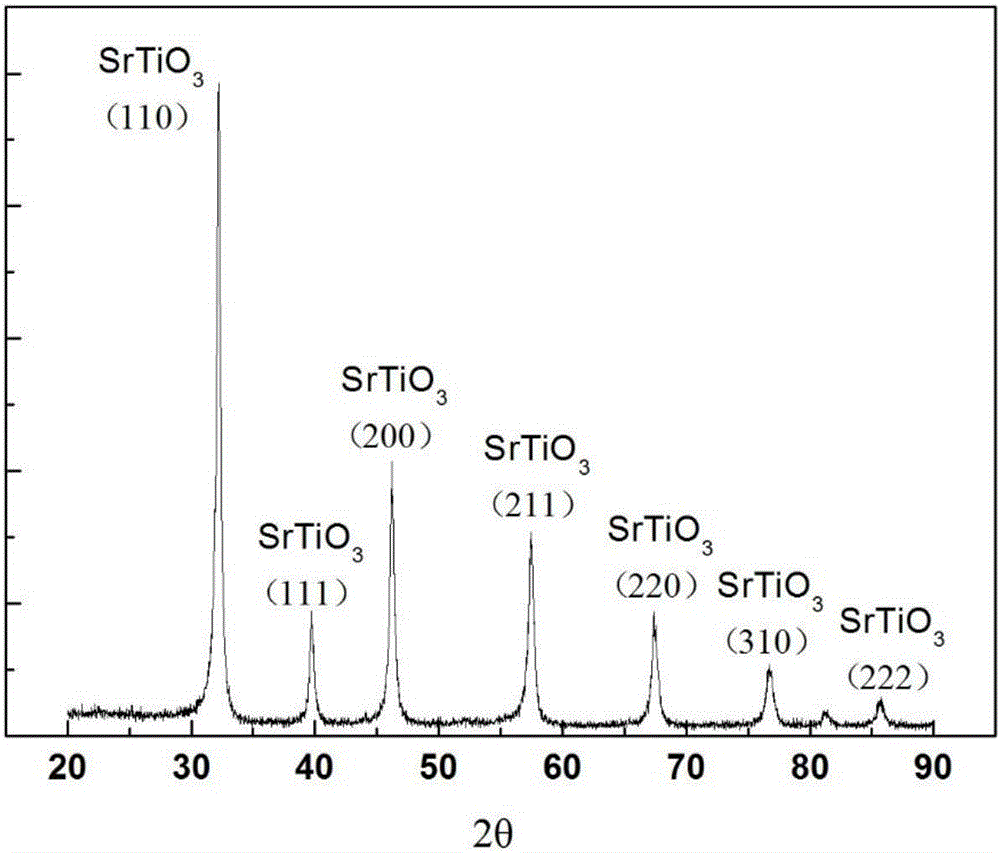

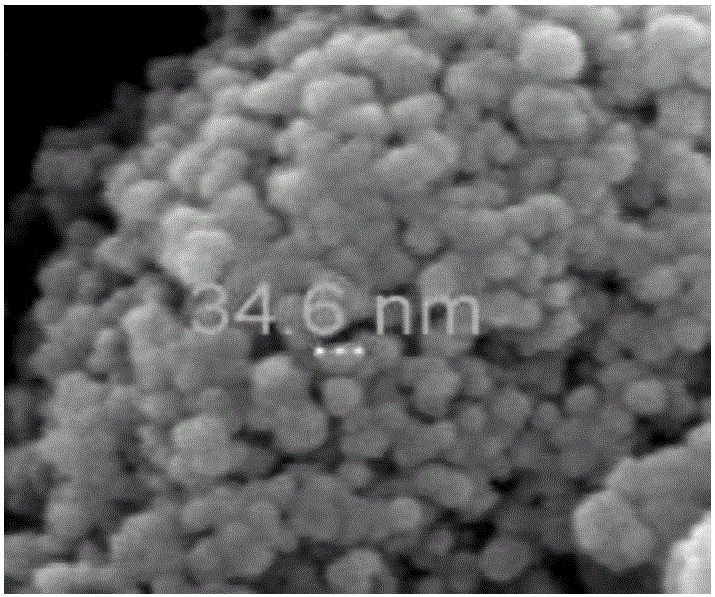

[0023] 1. Preparation of 20% Nb-doped SrTiO by hydrothermal method 3 Nano powder:

[0024] 1mmol Sr(NO 3 ) 2 and 12.5mmol of NaOH were dissolved in 10ml of deionized water to obtain solution A, 0.8mmol of tetrabutyl titanate and 0.2mmol of niobium ethoxide were dissolved in 5ml of anhydrous butanol to obtain solution B, and 2.5ml of oleic acid was dissolved in 5ml of Obtain solution C in anhydrous butanol, mix solution A, solution B, and solution C and stir until the solutions are evenly mixed, transfer the mixed solution to a 50ml reaction water heating kettle, and react at 200°C for 24 hours after sealing, after the reaction is completed Naturally cooled to room temperature, centrifuged and washed 4 times with deionized water, and finally baked at 80 °C for 48 hours to obtain Nb-doped SrTiO 3 Nano powder.

[0025] 2. Preparation of composite slurry:

[0026] Weigh 0.002g of Nb-doped SrTiO prepared in step 1 3 Nanopowder, and 0.398g of titanium dioxide to mix the two, N...

Embodiment 2

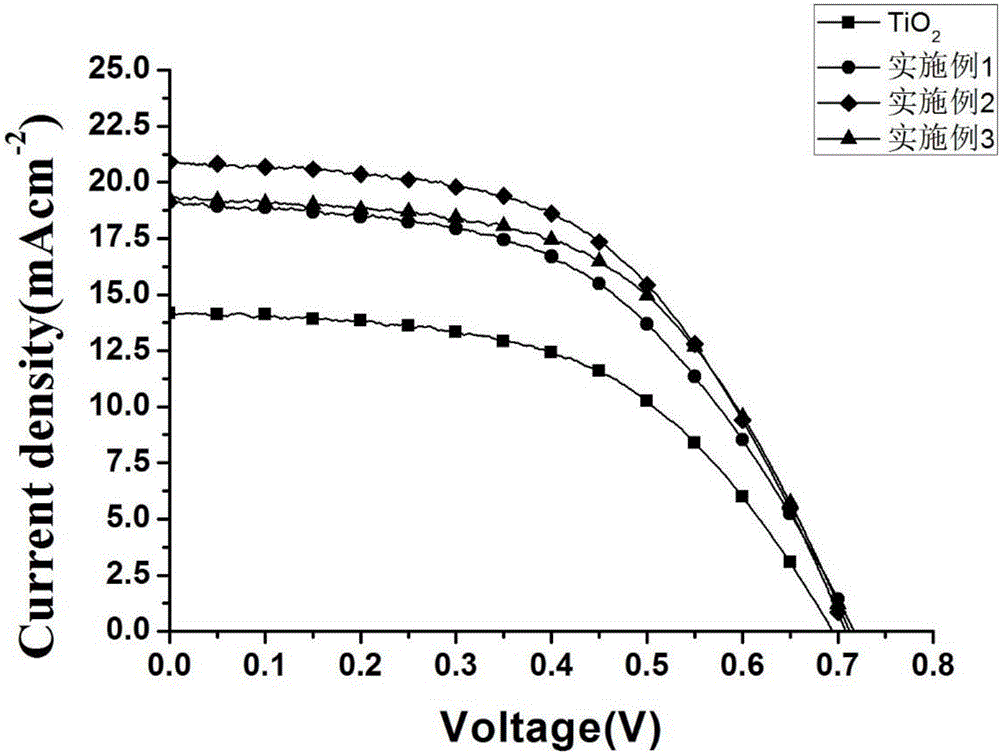

[0032] This example discloses a method for preparing a composite photoanode, the preparation process of which is the same as that of Example 1, the only difference being that in the preparation of the composite slurry in step 2, the Nb-doped SrTiO 3 The mass of nanopowder is 0.004g, and the mass of titanium dioxide is 0.398g. After the two are mixed, Nb-doped SrTiO 3 The nano-powder accounts for 1% of the total mass of the mixed powder, and titanium dioxide accounts for 99%. The photoelectric test is carried out on the photoanode, and the test results are as follows: open circuit voltage: 0.709V, short-circuit current density: 20.90mA / cm 2 , fill factor: 0.53, photoelectric conversion efficiency: 7.855%.

Embodiment 3

[0034] This example discloses a method for preparing a composite photoanode, the preparation process of which is the same as that of Example 1, the only difference being that in the preparation of the composite slurry in step 2, the Nb-doped SrTiO 3 The mass of nano powder is 0.02g, the mass of titanium dioxide is 0.38g, and the Nb-doped SrTiO 3 The nano powder accounts for 5% of the total mass of the mixed powder, and titanium dioxide accounts for 95%. The photoelectric test is carried out on the photoanode, and the test results are as follows: open circuit voltage: 0.713V, short circuit density: 19.26mA / cm 2 , fill factor: 0.55, photoelectric conversion efficiency: 7.523%.

[0035] attached by image 3 It can be seen that the Nb-doped SrTiO prepared by the present invention 3Compared with the traditional titanium dioxide photoanode, the current density of the photoanode with different proportions of nano powder and titanium dioxide is better than that of the traditional ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com