Anode dye soaking device of solar cell and dye soaking method

A technology of solar cells and dyes, applied in circuits, capacitors, photovoltaic power generation, etc., can solve problems such as high temperature sintering and unsatisfactory dye adsorption, and achieve the effects of improving soaking quality, improving material utilization, and saving dye consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a solar cell anode dye soaking device, and further provides a dye soaking method using the device to further complete battery production.

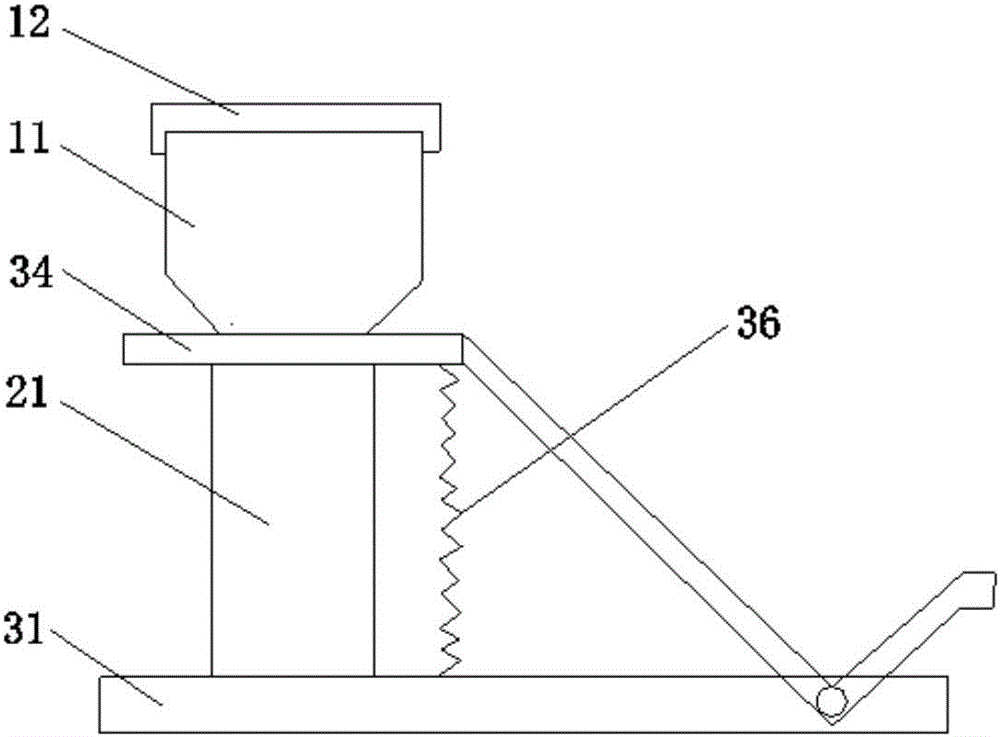

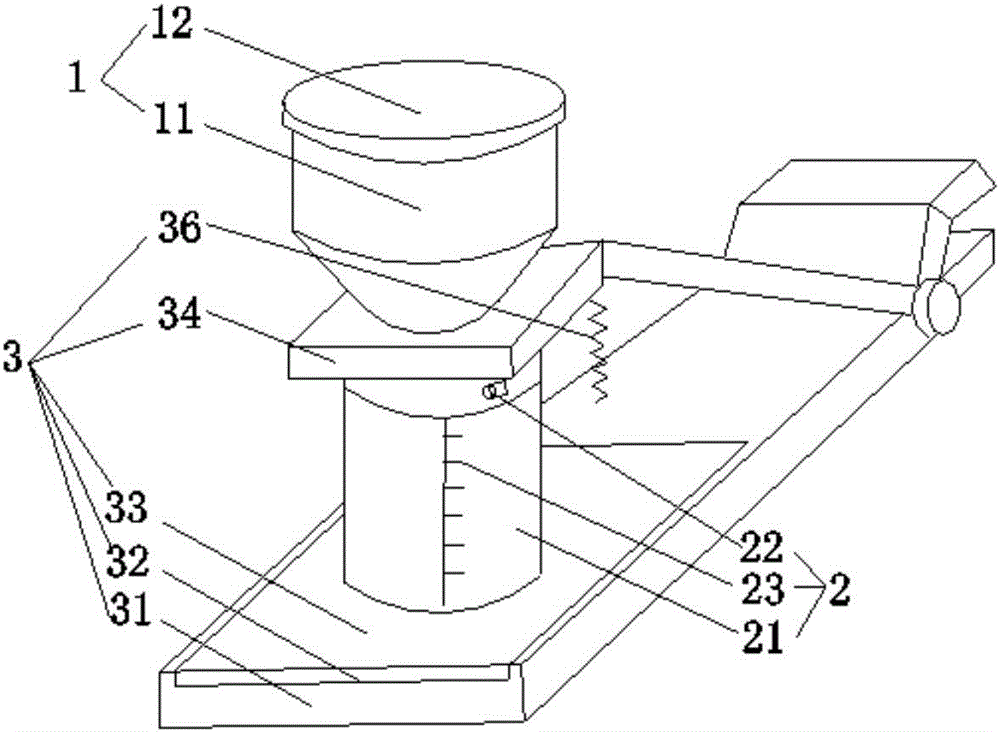

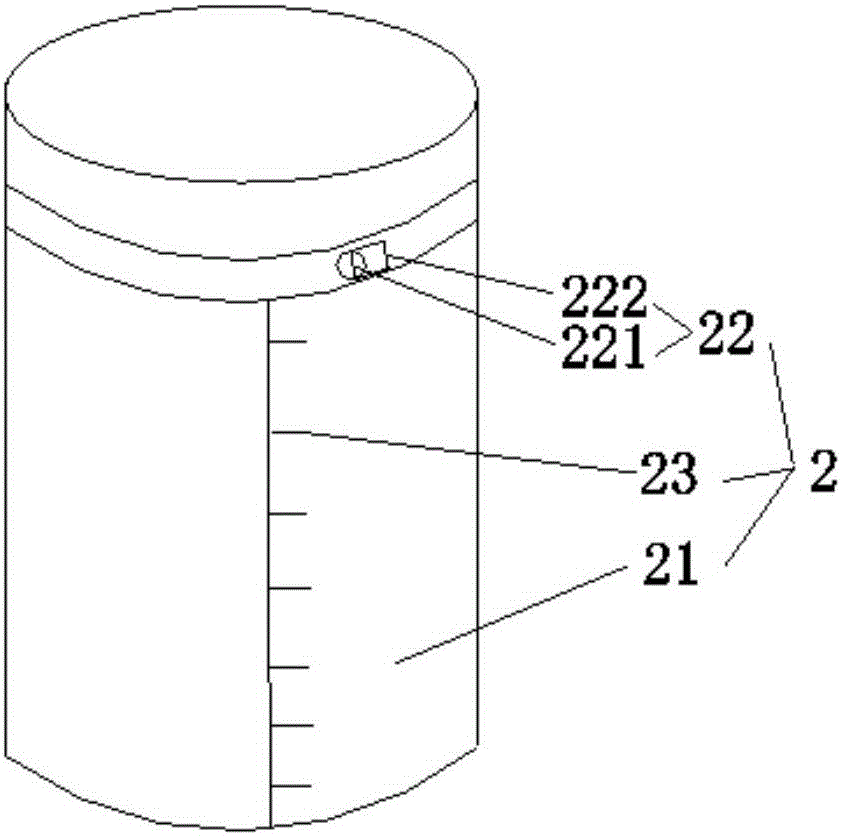

[0035] as attached figure 1 , attached figure 2 As shown, the solar cell anode dye soaking device includes a storage bin 1 , a soaking bin 2 and a base 3 which are detachably connected in sequence.

[0036] The storage bin 1 includes a storage bin body 11 with an open top, a sealing cover 12 that can cover and seal the storage bin body, the bottom of the storage bin body 11 is provided with a valve, and the internal space of the storage bin body 11 passes through the valve It communicates with the inner space of the soaking chamber 2. In this embodiment, the opening or closing of the valve is controlled by a valve switch, which is a sheet structure that can cover the valve. By adjusting the degree of cover of the valve by the sheet structure, the opening and closing of the valve and the adjustment of the ...

Embodiment 2

[0053] This embodiment provides a solar cell anode dye soaking device, and further provides a dye soaking method using the device to further complete battery production.

[0054] The solar cell anode dye soaking device used in this embodiment is the same as that in Embodiment 1, and the dye soaking method and the further method of completing the battery production using this device are different.

[0055] Specifically, the above device is used for battery production, and the production method includes:

[0056] S1. Preparation of conductive substrate: Cut the flexible conductive substrate polyethylene naphthalate (PEN) / indium tin oxide (ITO) to a suitable size, clean it with deionized water and isopropanol in sequence, and then dry it ;

[0057] S2, oxide semiconductor TiO 2 Preparation of thin film: TiO 2 The colloidal solution is prepared on the flexible substrate layer prepared in step 1 by scraping at room temperature. After drying, apply a pressure of 30Mpa with a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com