Composite laminated perovskite solar cell and manufacturing method therefor

A technology of solar cells and composite stacking, applied in the field of solar cells, can solve the problems that restrict the process of industrialization development and the complex preparation process of multi-junction solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

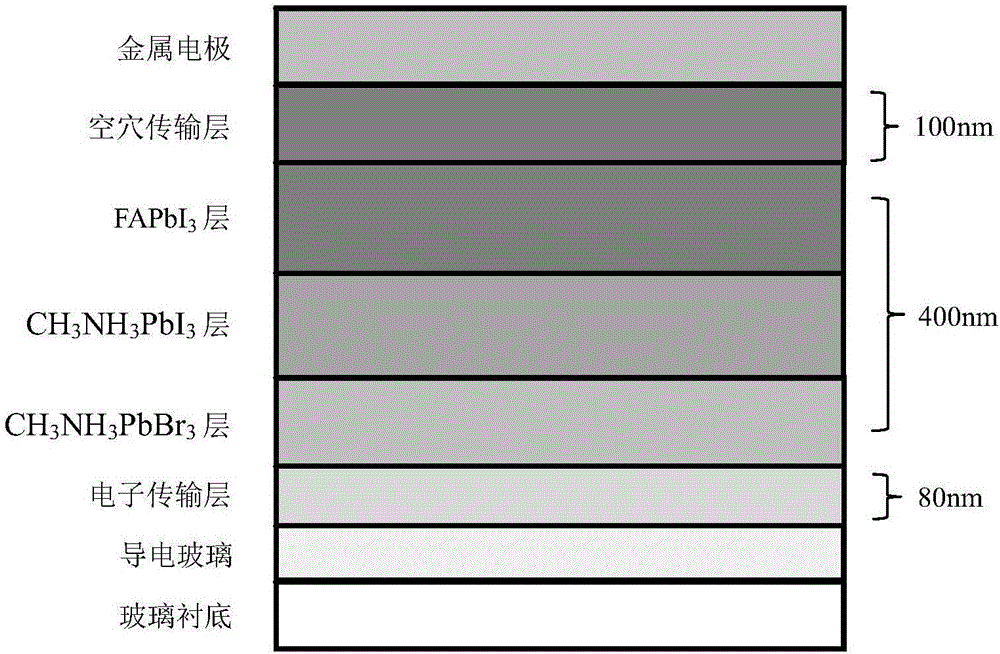

[0017] like figure 1 Shown: from bottom to top are glass substrate, conductive glass FTO, electron transport layer TiO 2 , the first perovskite light-absorbing layer CH 3 NH 3 PbBr 3 , the second perovskite light-absorbing layer CH 3 NH 3 PB 3 , the third perovskite light-absorbing layer FAPbI 3 , hole transport layer Spiro-MeOTAD and metal electrodes. The thickness of the glass substrate and conductive glass FTO is 200nm, the thickness of the electron transport layer is 80nm, the thickness of the hole transport layer is 100nm, CH 3 NH 3 PbBr 3 Layer thickness 130nm, CH 3 NH 3 PB 3 Layer thickness 130nm, FAPbI 3 The thickness of the layer is 140nm, and the total thickness of the laminated perovskite light-absorbing layer is 400nm. The metal Ag electrode has a thickness of 100 nm.

[0018] Step 1. Preparation of transparent e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com