Nickel sulfide/graphene composite material and preparation method and application thereof

A composite material and graphene technology, applied in the field of composite materials, can solve the problems of difficulty in obtaining nickel sulfide, affecting the electrochemical performance of composite materials, etc., and achieve the effect of improving energy, cycle performance and rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

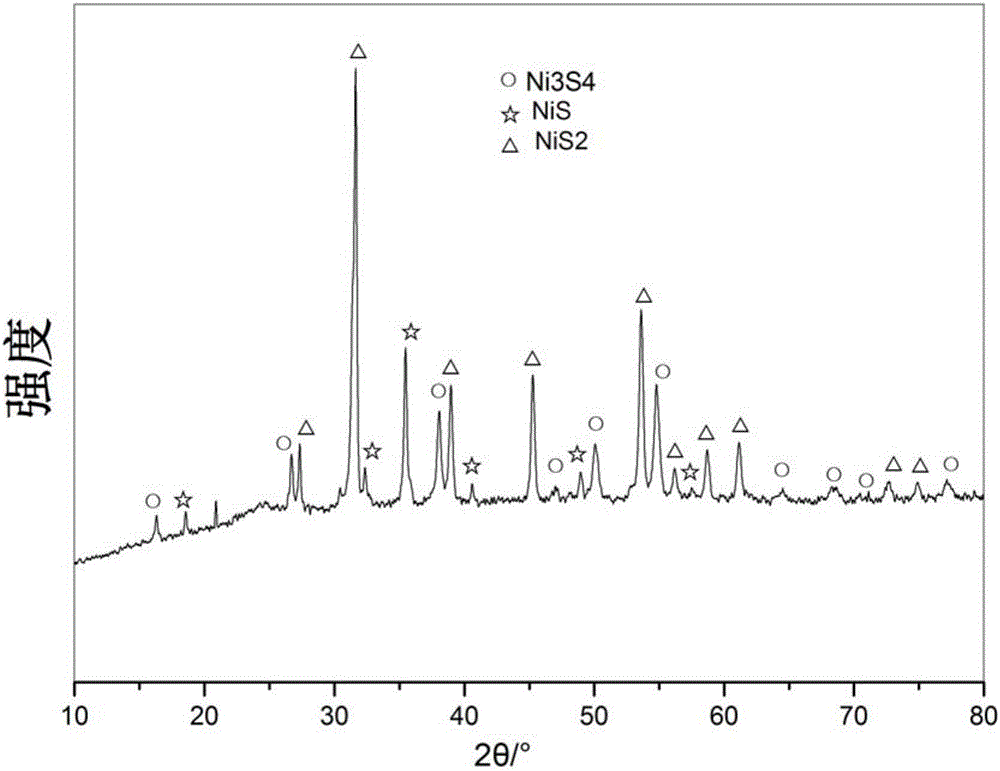

Embodiment 1

[0030] 1. Preparation method

[0031] 1. Dissolve 30mg of GO (graphene oxide) in deionized water, and sonicate for 2 hours.

[0032] 2. Take 2mmol NiSO 4 ·6H 2 O in 10mL of deionized water, stirred evenly to obtain a homogeneous solution. This solution was slowly added dropwise to the mixture in step 1, and stirred for 4h.

[0033] 3. Take 5mmolNa 2 S 2 o 3 ·5H 2 O in 10mL deionized water, stirred evenly to obtain a homogeneous solution. This solution was slowly added dropwise to the mixture in step 2, and stirred for 1 h.

[0034] 4. Transfer the mixed solution in step 3 into a reaction kettle, and react in an incubator at 160°C for 18 hours.

[0035] 5. The reactor in step 4 is naturally cooled to room temperature. The mixture was filtered and dried at 80°C for 5 hours. A black powdery substance was obtained.

[0036] 6. Put the black powder solid in step 5 in a tube furnace, and calcinate at 450° C. for 5 hours under an Ar atmosphere to obtain a composite of nic...

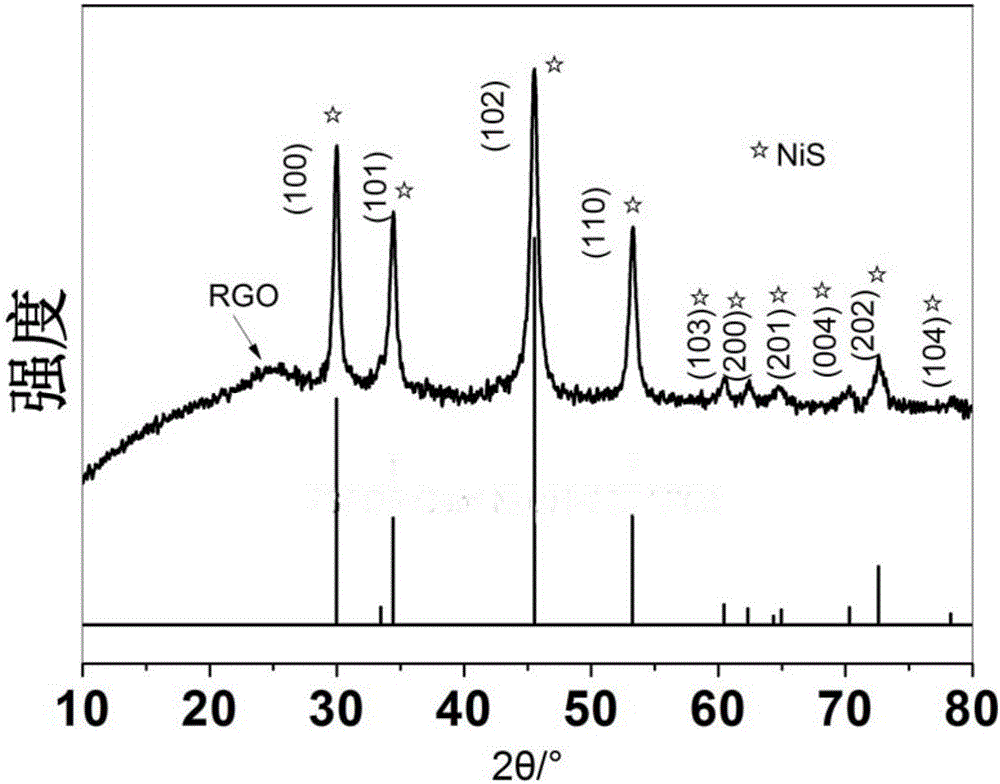

Embodiment 2

[0045] 1. Preparation method

[0046] 1. Dissolve 50mg of GO (graphene oxide) in deionized water and ultrasonicate for 2 hours.

[0047] 2. Take 2mmol NiSO 4 ·6H 2 O in 10mL of deionized water, stirred evenly to obtain a homogeneous solution. This solution was slowly added dropwise to the mixture in step 1, and stirred for 4h.

[0048] 3. Take 5mmolNa 2 S 2 o 3 ·5H 2 O in 10mL deionized water, stirred evenly to obtain a homogeneous solution. This solution was slowly added dropwise to the mixture in step 2, and stirred for 1 h.

[0049] 4. Transfer the mixed solution in step 3 into a reaction kettle, and react in an incubator at 200°C for 18 hours.

[0050] 5. The reactor in step 4 is naturally cooled to room temperature. The mixture was filtered and dried at 80°C for 5 hours. A black powdery substance was obtained.

[0051] 6. Put the black powder solid in step 5 in a tube furnace, and calcinate at 450° C. for 5 hours under an Ar atmosphere to obtain a composite of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com