Tin selenide and tin oxide composite material and preparation method and application thereof

A composite material, tin oxide technology, applied in nanotechnology for materials and surface science, electrochemical generators, electrical components, etc., can solve the problems of reducing material energy density, complex preparation process, harsh reaction conditions, etc. Excellent rate performance, simple and reliable method, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

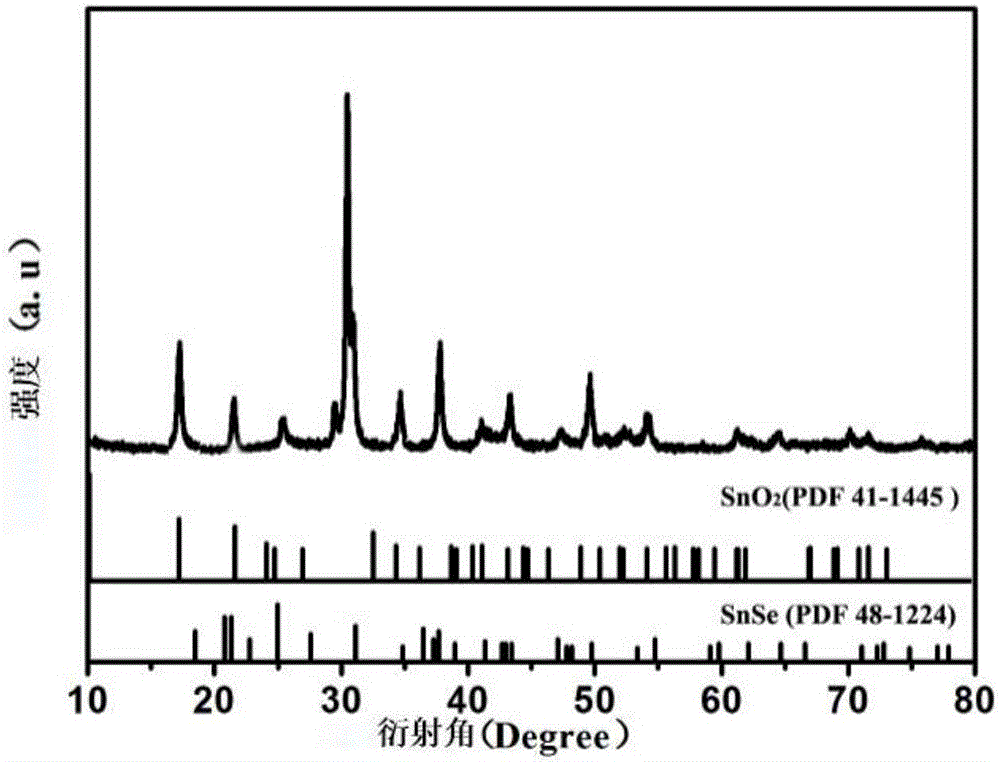

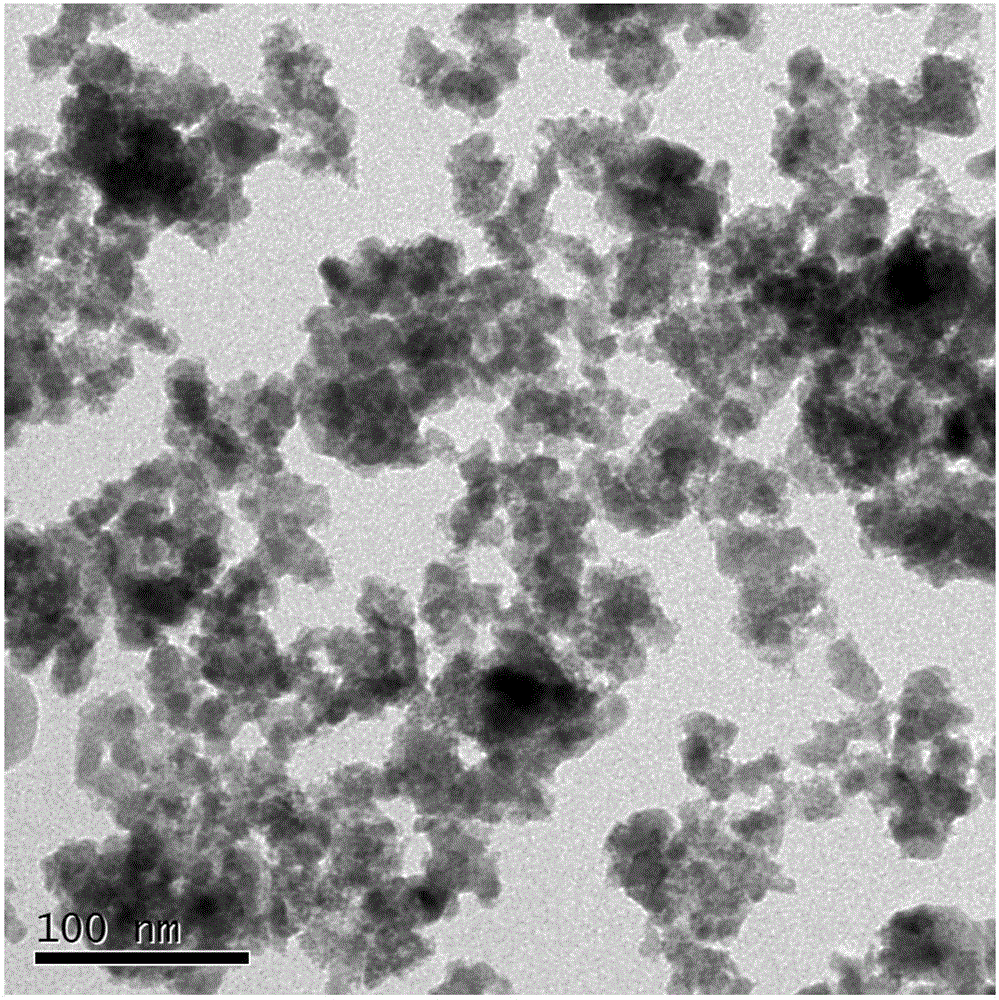

[0043] First, dissolve 0.5 mol of sodium hydroxide in 100 mL of aqueous solution, then add 0.003 mol of selenium powder, stir at 80°C to fully dissolve it, and obtain a selenium-containing alkaline solution. Dissolve 0.4 mol of citric acid in 100 mL of aqueous solution, then add 0.003 mol of tin dichloride dihydrate, stir well to dissolve it, and obtain a tin-containing acidic solution. Then the above two solutions were mixed, heated and stirred at 90°C for 8h, then the reaction precipitate was washed with water and absolute ethanol, filtered with suction, dried, and finally placed in a muffle furnace, heated at 10°C / min in an air atmosphere to 350°C, keep warm for 5 minutes, and cool naturally to obtain the tin selenide / tin oxide composite material. XRD results show that the substance is a mixed phase of tin selenide and tin dioxide. From figure 2 It can be seen that the complex is irregular nanoparticles with a particle diameter of 10-70nm.

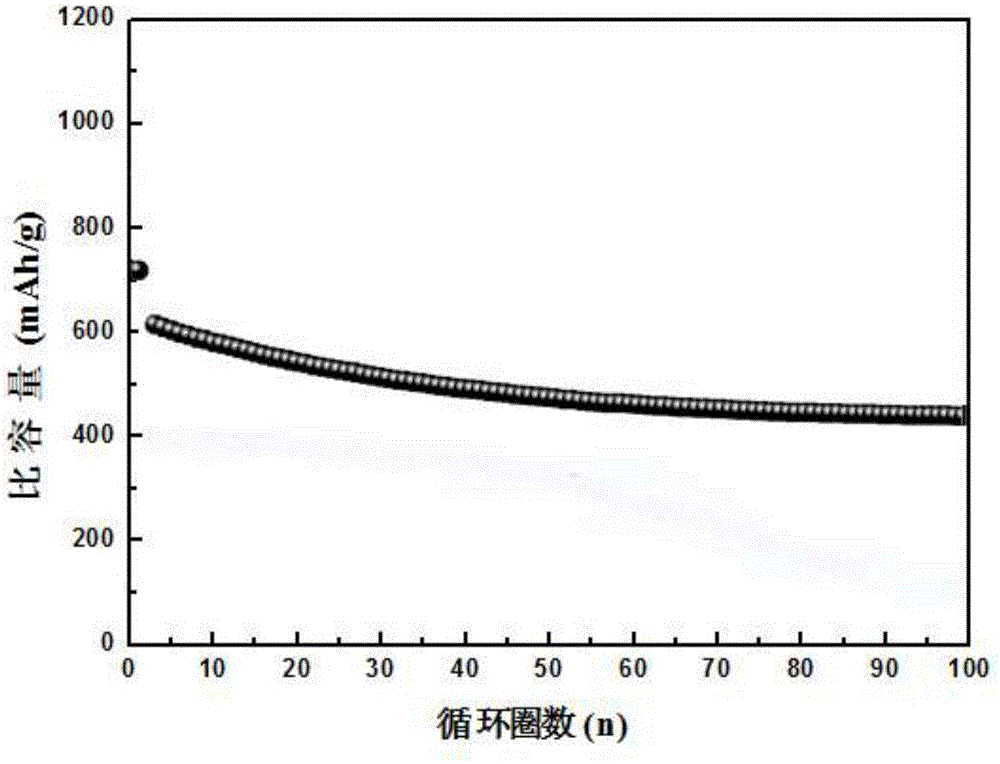

[0044] The sodium-ion half-b...

Embodiment 2

[0046] First, dissolve 0.5 mol of sodium hydroxide in 100 mL of aqueous solution, then add 0.004 mol of selenium powder, and stir at 80°C to fully dissolve it to obtain a selenium-containing alkaline solution. Dissolve 0.4 mol of citric acid in 100 mL of aqueous solution, then add 0.004 mol of tin dichloride dihydrate, stir well to dissolve it, and obtain a tin-containing acidic solution. Then the above two solutions were mixed, heated and stirred at 90°C for 10h, then the reaction precipitate was washed with water and absolute ethanol, filtered with suction, dried, and finally placed in a muffle furnace, heated at 10°C / min in an air atmosphere to 350°C, keep warm for 5 minutes, and cool naturally to obtain the tin selenide / tin oxide composite material.

[0047] The sodium-ion half-battery prepared in this example can still maintain a specific discharge capacity of 405 mAh / g after 100 cycles at a constant current discharge density of 200 mA / g. The lithium-ion half-battery pre...

Embodiment 3

[0049] First, dissolve 0.4 mol of sodium hydroxide in 100 mL of aqueous solution, then add 0.004 mol of selenium powder, stir at 80°C to fully dissolve it, and obtain an alkaline solution containing selenium. Dissolve 0.35 mol of citric acid in 100 mL of aqueous solution, then add 0.004 mol of tin dichloride dihydrate, stir well to dissolve it, and obtain a tin-containing acidic solution. Then the above two solutions were mixed, heated and stirred at 80°C for 10h, then the reaction precipitate was washed with water and absolute ethanol, filtered with suction, dried, and finally placed in a muffle furnace, heated at 10°C / min in an air atmosphere to 330°C, keep warm for 5 minutes, and cool naturally to obtain the tin selenide / tin oxide composite material.

[0050] The sodium-ion half-battery prepared in this example can still maintain a specific discharge capacity of 400 mAh / g after 100 cycles at a constant current discharge density of 200 mA / g. The lithium-ion half-battery pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com