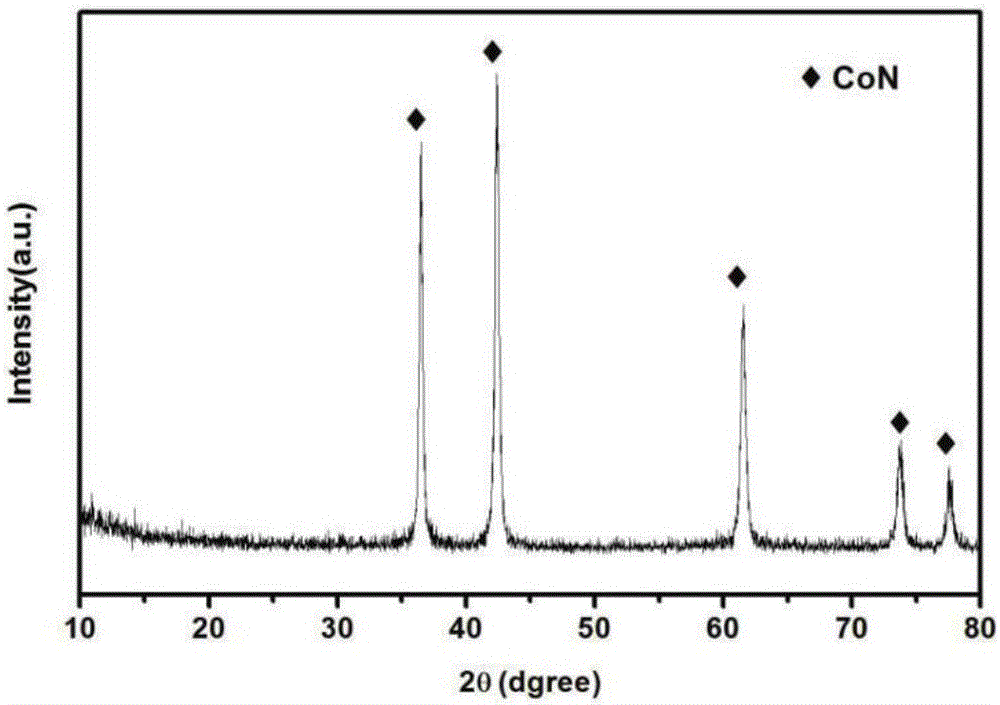

Cobalt nitride nanometer cubic-nitrogen doped carbon composite material, preparation method and application

A technology of cobalt nitride nanometer and nitrogen-doped carbon, which is applied in the direction of fuel cell type half cell and secondary cell type half cell, structural parts, electrical components, etc. problems, to achieve uniform morphology, high conductivity, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

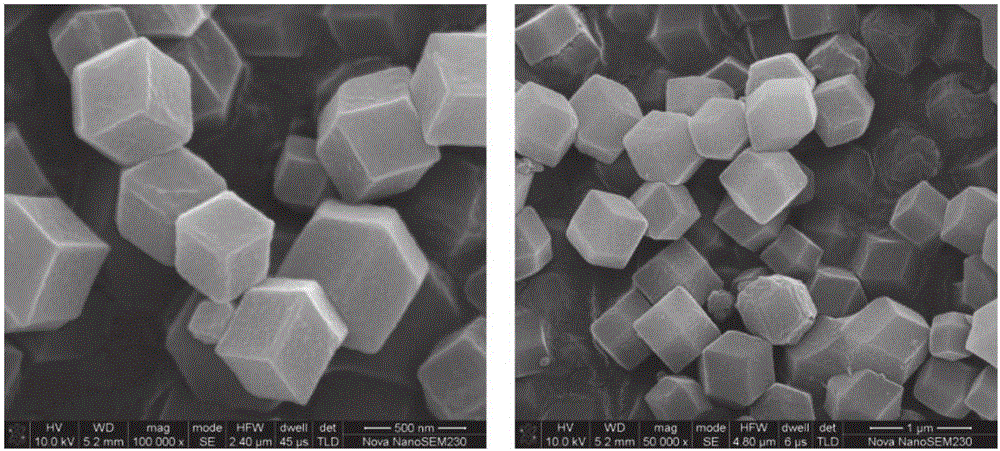

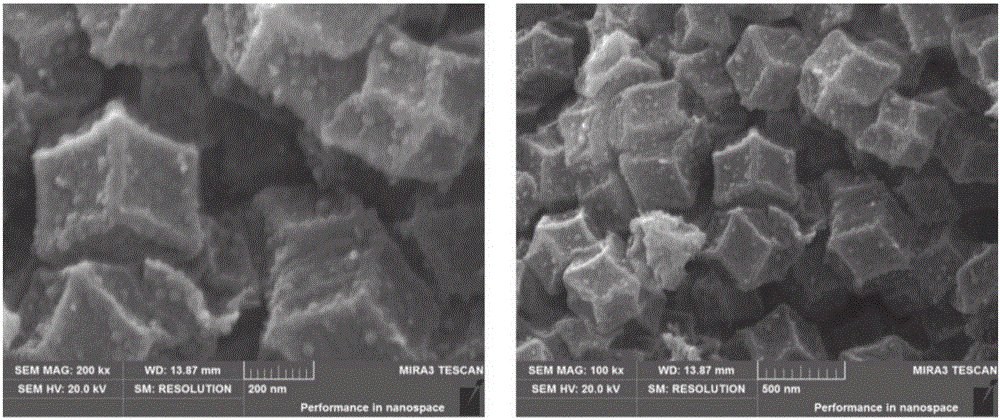

Embodiment 1

[0069] Step (1): Take 2.94g of cobalt nitrate and 0.9g of polyvinylpyrrolidone and add them into 200ml of methanol at the same time, and stir magnetically for 30min to form a dispersion. Dissolve 11.6g of 2-methylimidazole in 200ml of methanol solution, stir the same for 30min and then quickly mix the two dispersions. After magnetic stirring for 1h, a uniformly dispersed precursor solution is obtained. Stand and purify at room temperature for 24h, resulting in a purple precipitate , the product was filtered and washed alternately with methanol and deionized water for 3 times, and dried in a vacuum oven at 60°C for 24 hours to obtain a nanoscale metal-organic framework complex; the particle size of the prepared nanoscale metal-organic framework complex was 70nm , the specific surface area is 900m2 / g, and the pore volume is 0.3cm3 / g.

[0070] Step (2): After transferring the nanoscale metal-organic framework complex prepared in step (1) to a tube furnace, heat it from room tempe...

Embodiment 2

[0075] Step (1): Take 2.32g of cobalt nitrate and 0.7g of polyvinylpyrrolidone and add them into 200ml of methanol at the same time, and stir magnetically for 30min to form a dispersion. Dissolve 3.3g of 2-methylimidazole in 200ml of methanol solution, stir the same for 30min and then quickly mix the two dispersions. After magnetic stirring for 1h, a uniformly dispersed precursor solution is obtained. Stand and purify at room temperature for 18h, resulting in a purple precipitate , the product was filtered and washed alternately with methanol and deionized water for 3 times, and dried in a vacuum oven at 60°C for 24 hours to obtain a nanoscale metal-organic framework complex; the particle size of the prepared nanoscale metal-organic framework complex was 60nm, the specific surface area is 850m 2 / g, the pore volume is 0.3cm 3 / g.

[0076] Step (2): After transferring the nanoscale metal-organic framework complex prepared in step (1) to a tube furnace, heat it from room tempe...

Embodiment 3

[0081]Step (1): Take 2.94g of cobalt nitrate and 0.3g of polyvinylpyrrolidone and add them into 200ml of methanol at the same time, and stir magnetically for 30min to form a dispersion. Dissolve 8.2g of 2-methylimidazole in 200ml of methanol solution, stir for 30min and quickly mix the two dispersions. After magnetically stirring for 1h, a uniformly dispersed precursor solution is obtained. Stand and purify at room temperature for 24h, resulting in a purple precipitate , the product was filtered and washed alternately with methanol and deionized water for 3 times, and dried in a vacuum oven at 60°C for 12 hours to obtain the nanoscale metal-organic framework complex; the particle size of the obtained nanoscale metal-organic framework complex was 80nm, the specific surface area is 950m 2 / g, the pore volume is 0.35cm 3 / g.

[0082] Step (2): After transferring the nanoscale metal-organic framework complex prepared in step (1) to a tube furnace, heat it from room temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com