Preparation method and application of double-carbon-layer-coated nitrogen-doped polysulfide

A technology of polysulfide and nitrogen doping, which is applied in the preparation/purification of carbon, chemical instruments and methods, nickel compounds, etc., can solve the problems of single-line oxygen nucleophilic attack, low cycle life, large overpotential, etc. Good appearance, easy operation, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

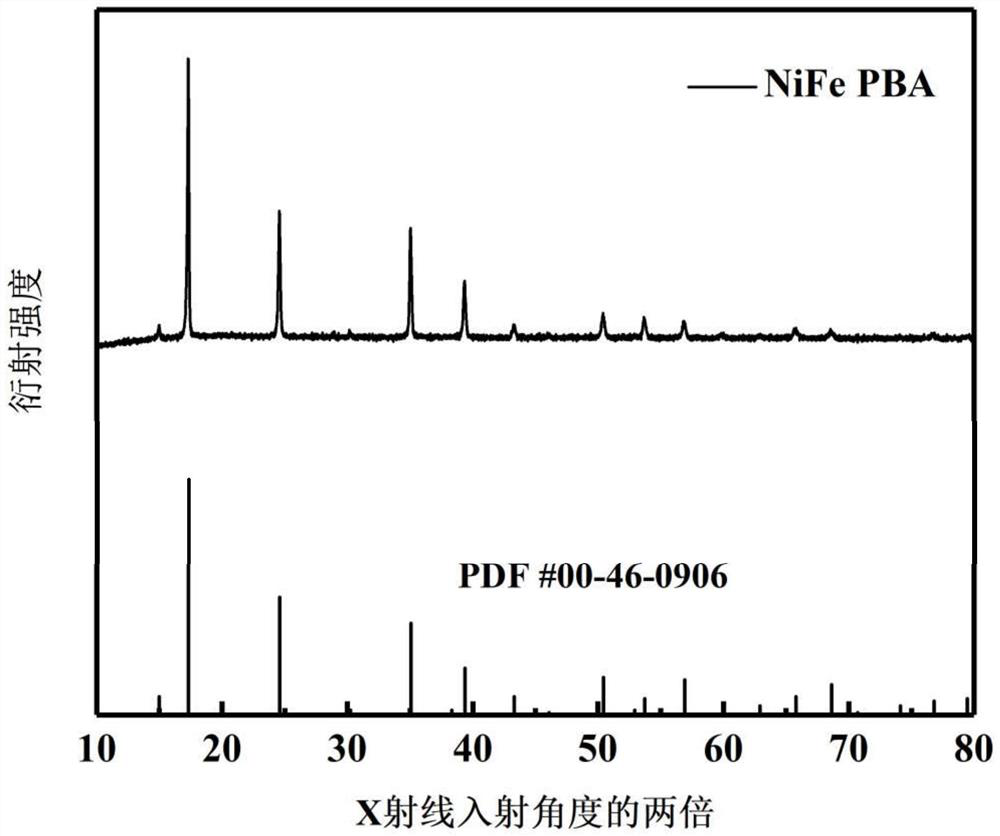

[0064] Ni-Fe-PBA cube nanocrystals with uniform size were synthesized by co-precipitation method: nickel chloride hexahydrate (3 mmol) and sodium citrate dihydrate (4.5 mmol) were dissolved in 100 mL deionized water to obtain solution A. Subsequently, the K containing 2mmol 3 Fe(CN) 6 100 mL of aqueous solution was slowly dropped into solution A, and vigorously stirred for 5 minutes. After aging at room temperature for 24 hours, the Ni-Fe-PBA nanocubes were collected by centrifugation (washed three times with deionized water and ethanol), and finally kept in an oven at 70 °C for 12 hours to obtain the precursor powder of Ni-Fe-PBA .

Embodiment 2

[0066] Take 100 mg of Ni-Fe PBA precursor powder and dissolve it uniformly in 120 ml of tris solution (pH=8) by ultrasonication for 1 hour. After stirring and sonicating for 60 minutes, 80 mg of dopamine hydrochloride was added, and the stirring was continued for 6 hours, then collected by suction filtration, and finally kept in an oven at 70°C for 12 hours to obtain the Ni-Fe PBA@PDA product.

Embodiment 3

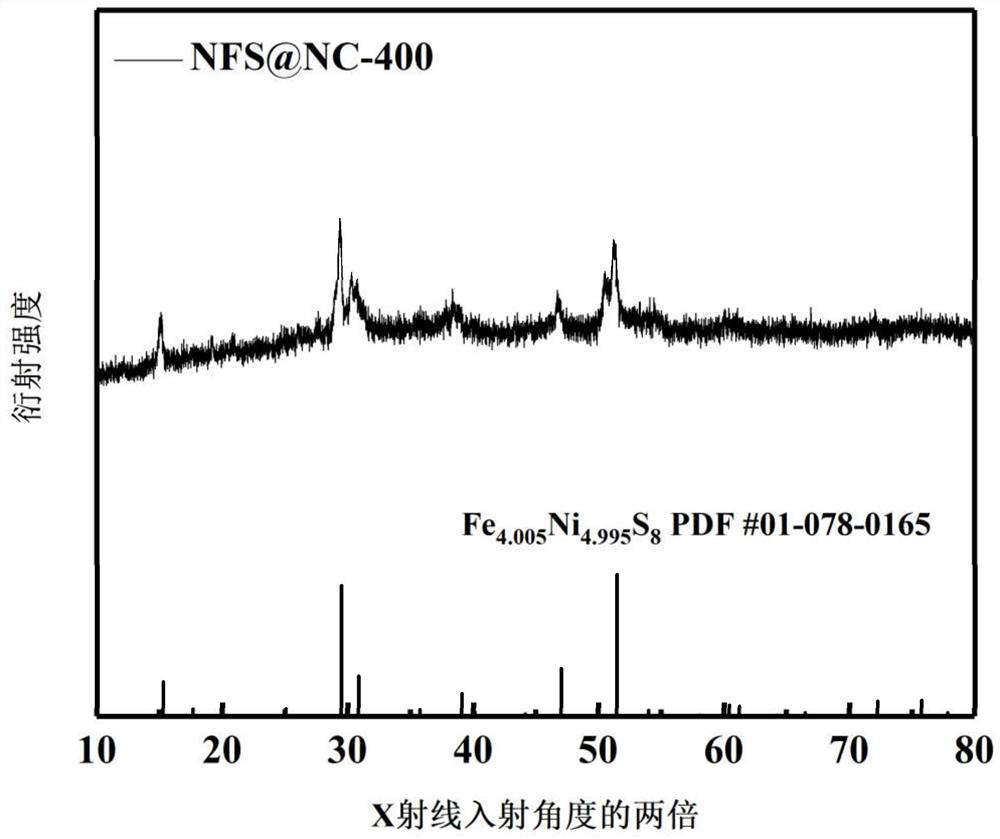

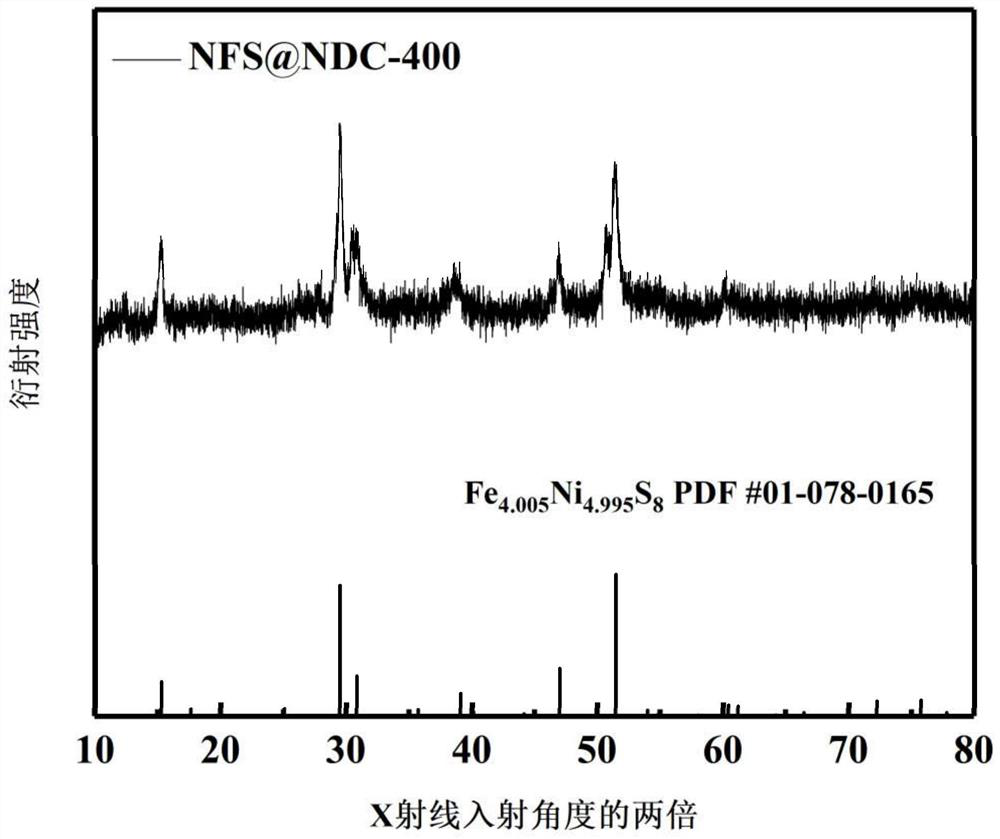

[0068] Weigh 2g of prepared Ni-Fe-PBA@PDA and 8g of sulfur powder, and grind them thoroughly. The mixture was placed in a corundum crucible. Before calcination, it is necessary to pass inert gas and hydrogen gas into the tube furnace in advance for 1 hour, initially make the tube in an inert and reducing gas environment, and then 2 / Ar(5wt%H 2 ) environment at 3C min -1 The slope was initially vulcanized at 400°C for 2h. After natural cooling to room temperature, Fe 4.005 Ni 4.995 S 8 @NDC sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com